A board drying production line

A production line and plate technology, applied in the field of plate drying production line, can solve the problems of large space, low space utilization rate, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] This section will describe in detail the specific embodiments of the present invention, the preferred embodiments of which are shown in the accompanying drawings.

[0045] In the description of the present invention, it should be understood that orientation descriptions are involved, such as up, down, front, back, left, right, etc.

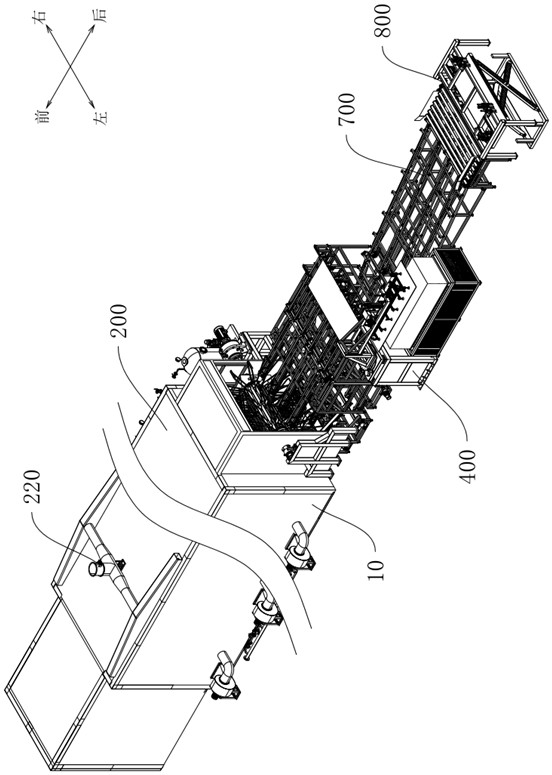

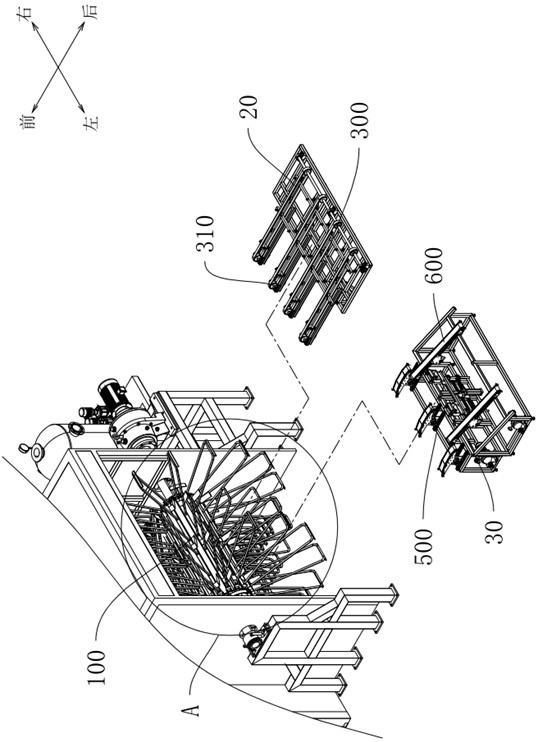

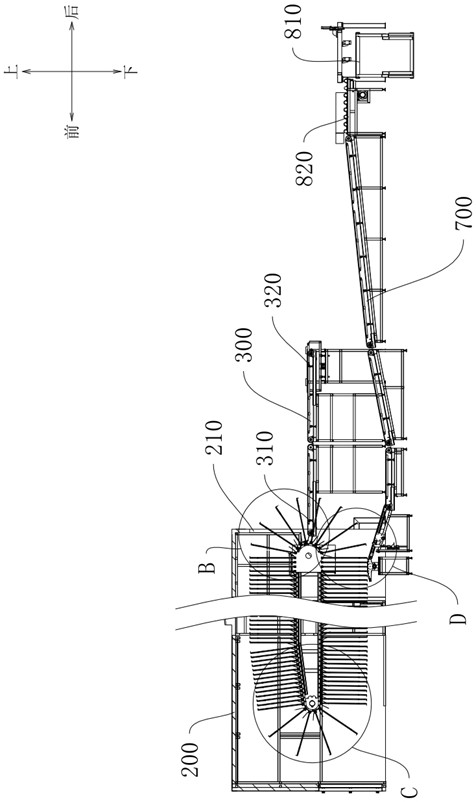

[0049] A plate drying production line, comprising: a circulating dryer 10, a plate feeding device 20, and a plate unloading device 30.

[0050] The plate feeding device 20 and the plate unloading device 30 are both arranged at the rear of the circulating dryer 10.

[0051] The circulating dryer 10 includes: a circulating conveying device 100 and an oven device 200.

[0052] The endless conveying device 100 includes a conveying driving member 110 and a plurality of belt plate members 120. a plurality of the strips

[0053] The circulation track includes the end-to-end feeding section, the upper drying section, the flap section, the lower drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com