High-performance bridge structure based on UHPC and FRP materials

A bridge structure, high-performance technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of stagnant leaves and impurities in plastic bottles in expansion grooves, and achieve the effect of good protection and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

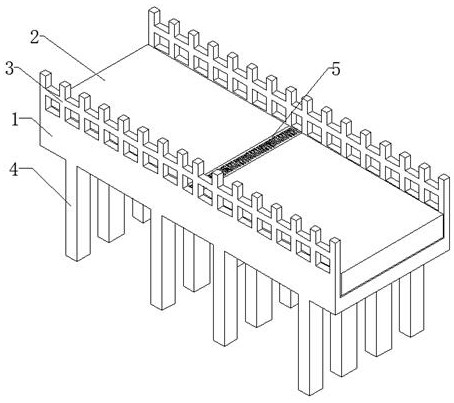

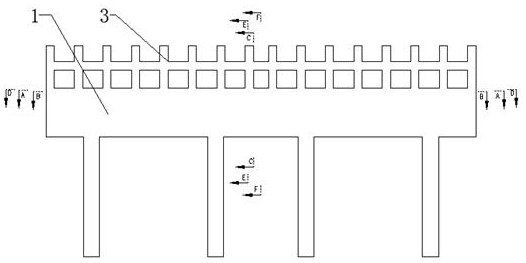

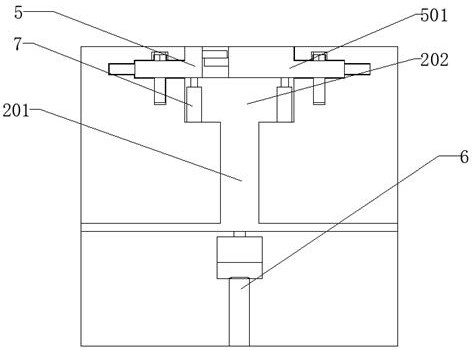

[0037] Such as Figure 1-13 As shown, a high-performance bridge structure based on UHPC and FRP materials includes a base 1, the upper surface of the base 1 is provided with a bridge deck 2, the upper surface of the bridge deck 2 is provided with an expansion joint 201, and the inner upper end of the expansion joint 201 There is a placement slit 202, and the inner end of the placement slit 202 is provided with a telescopic guide mechanism 5. The telescopic guide mechanism 5 includes a plurality of support plates 501, and the ends of each support plate 501 that are far away from each other run through the inner two sides of the placement slit 202 and are connected to each other. And it is connected to each other with the bridge deck 2. The inner lower end of the placement slot 202 is provided with a number of shock-absorbing buffer mechanisms 7. The upper end of each shock-absorbing buffer mechanism 7 is connected to each other between the telescopic guide mechanisms 5. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com