Self-compensation adjusting mechanism and method for new energy battery module welding

A battery module and adjustment mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding efficiency, high labor intensity, time-consuming and labor-intensive, etc., to improve positioning accuracy, Improve adjustment accuracy and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

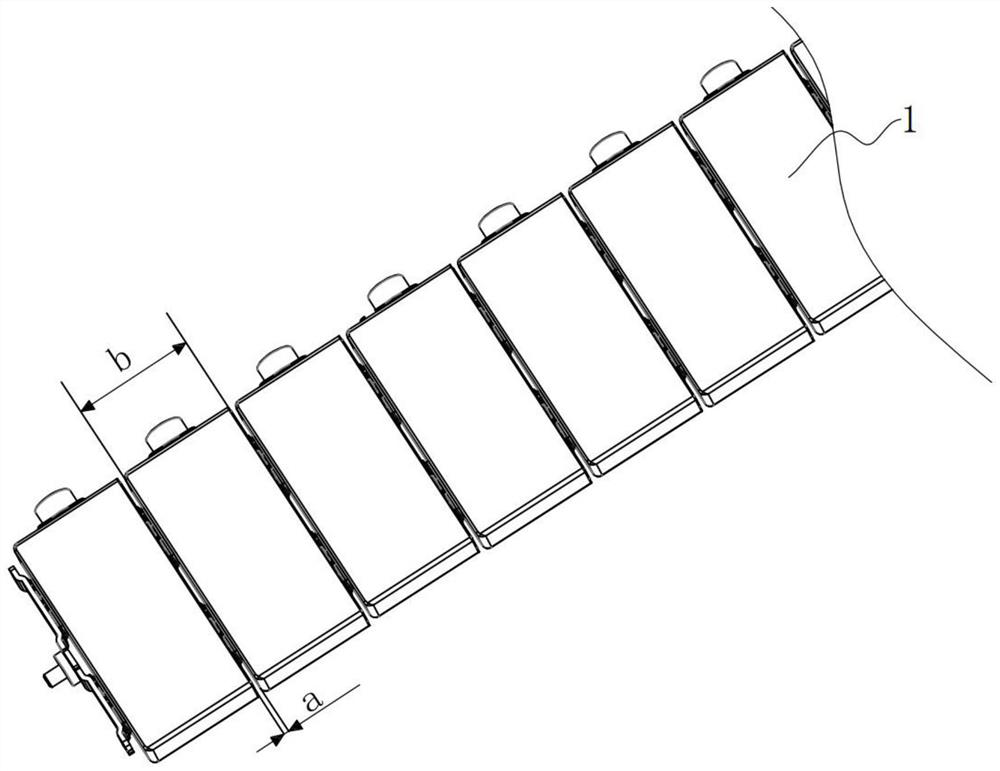

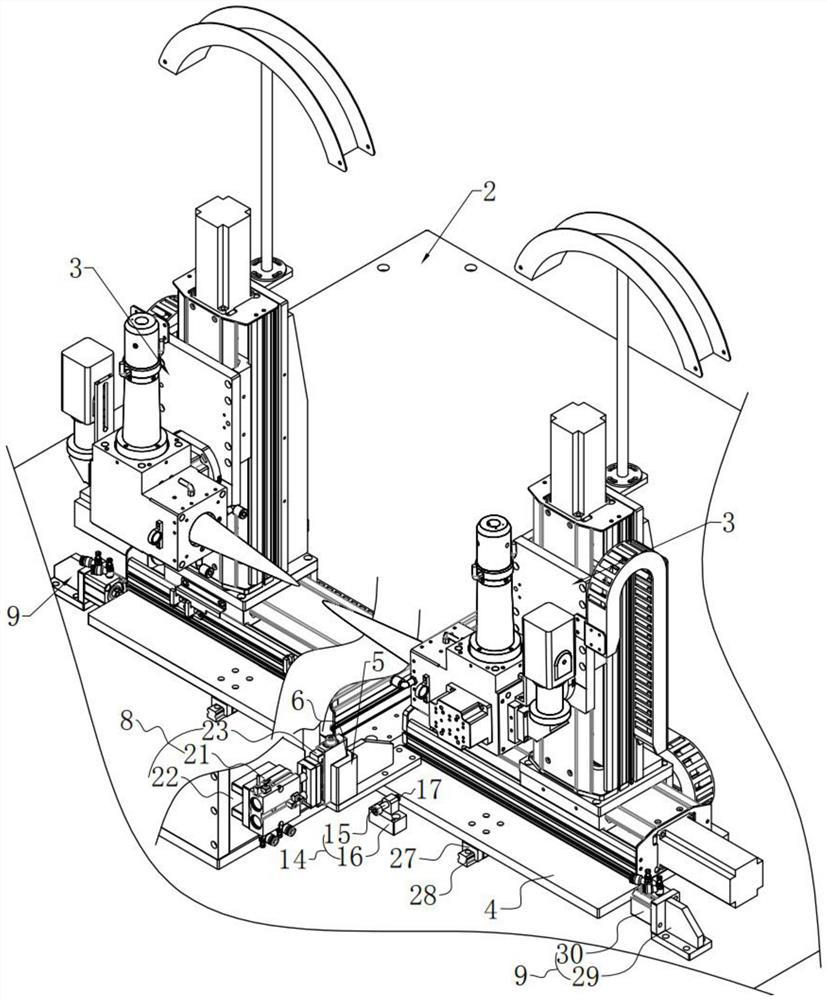

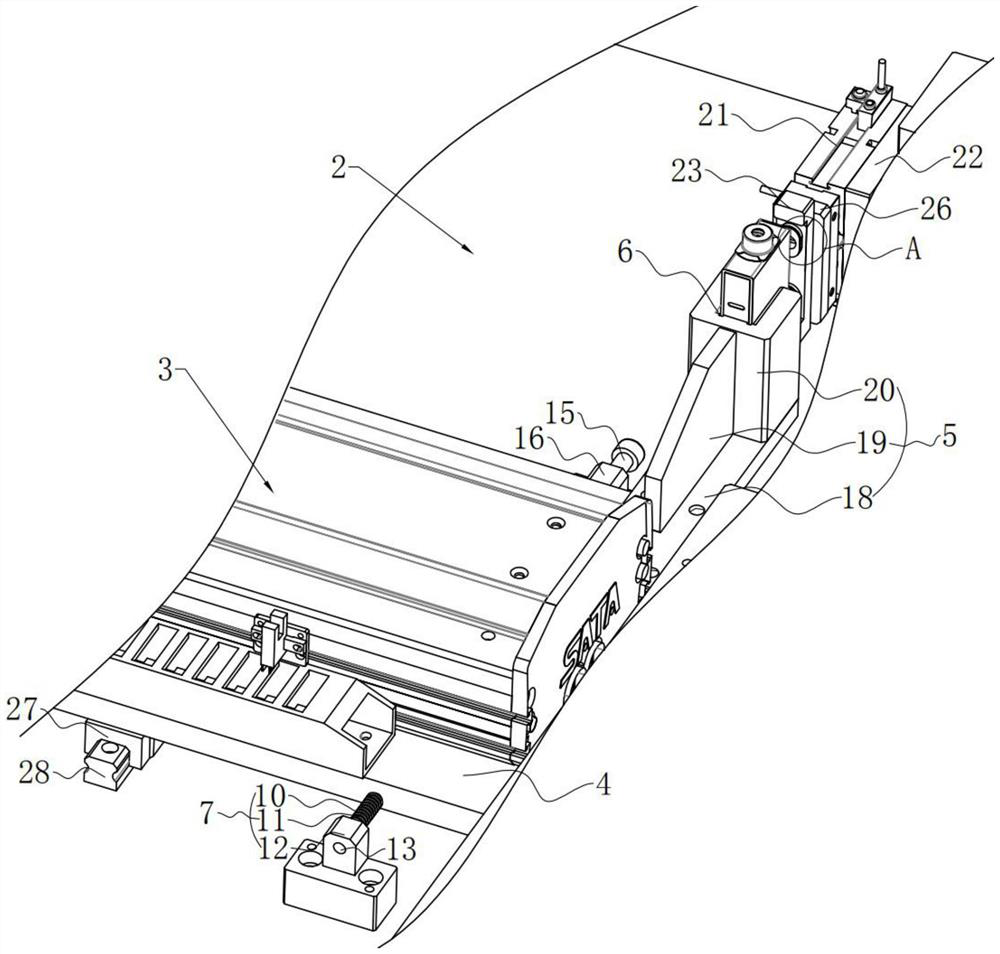

[0029] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings. It should be noted that the words "upper" and "lower" used in the following description refer to the attached figure 2 In the direction, the words "bottom" and "top" refer to the direction towards the geometric center of a specific component; the "width direction of the battery under test" in this paper is figure 1 In the direction of the width b of the battery, the "direction of the wiring on both sides of the welding torch mechanism" in this article is the same as figure 1 The width b direction of the battery in is parallel.

[0030]The most critical idea of the present invention is: through the measuring seat 5 and the through groove 6, the effect of fixing the battery to be tested is realized; The side connection direction is slidingly connected to the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com