Blasting vibration simulation impact device for shear rheological test

A blasting vibration and impact device technology, which is used in the direction of testing material strength, measuring devices, flow characteristics, etc. by using one-time impact force, can solve the problem of reducing the service life of horizontally dead-loaded electric cylinders, not suitable for small laboratories, and safety hazards of bullet launching paths To achieve the effect of maintaining the test accuracy and service life and improving the ability to resist risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

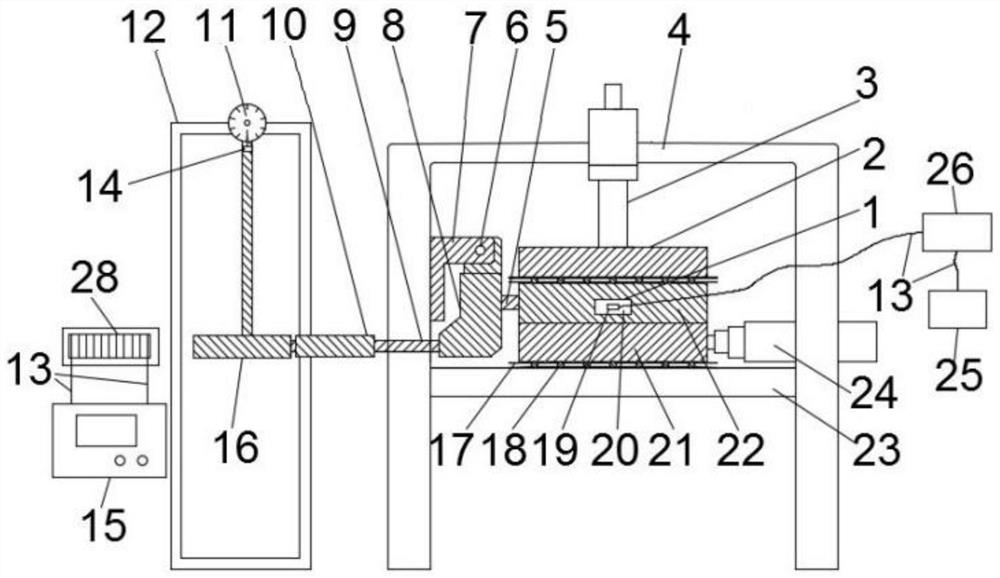

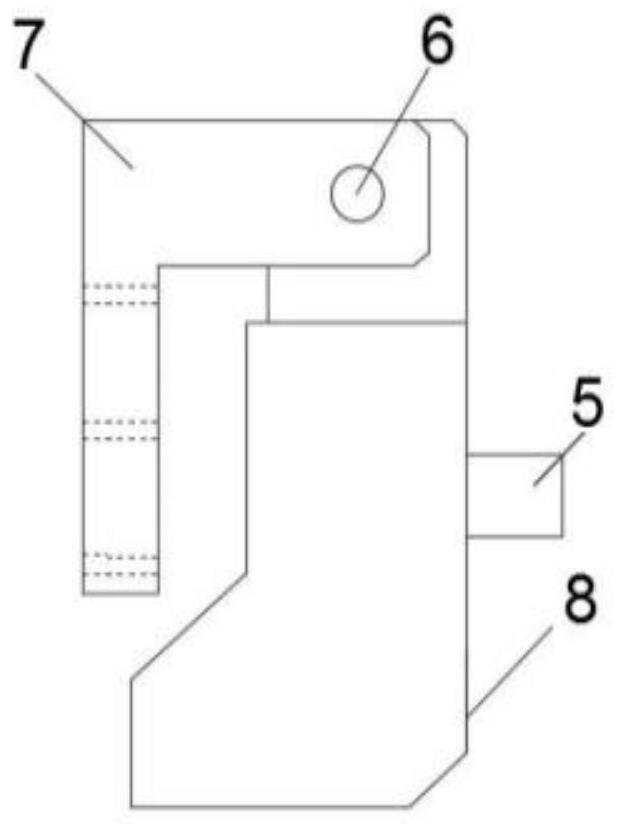

[0031] Embodiment 1: the present invention provides a kind of blasting vibration simulation impact device for shear rheological test, its structure is as follows figure 1 As shown, including the impact load generation mechanism, transmission mechanism, strain recording mechanism and receiving mechanism.

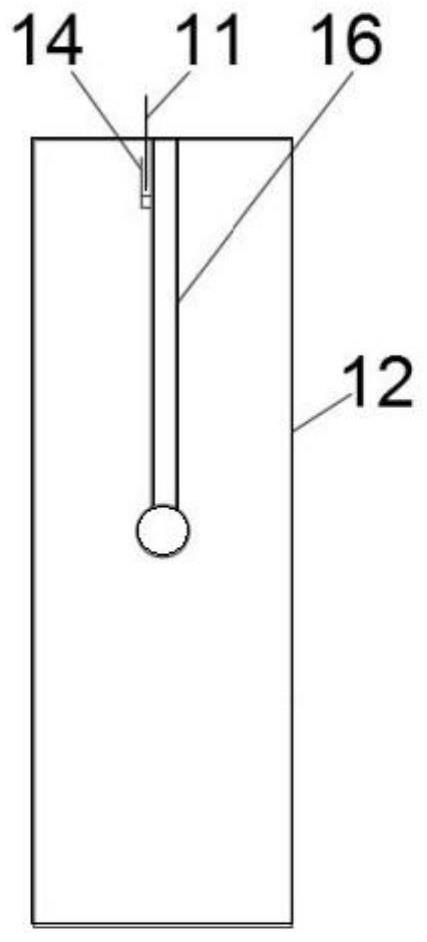

[0032] The generating mechanism of described impact load is impact load generating mechanism, is provided with pendulum 16, steel frame 12, current controller 15, lead 13, coil 28, pointer 14 and angle dial 11; The top is suspended, and the current controller is connected to the coil through wires. The current controller makes the coil generate magnetic fields of different strengths according to the input current value, and controls the swing of the pendulum through the magnetic force; see figure 2 , the steel frame is fixed with an angle dial, the angle dial is installed in front of the pendulum, the pointer is installed on the upper part of the pendulum and extends to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com