Rapid loading system for rocket launcher

A rocket launcher and loading technology, which is applied in the direction of weapon accessories, ammunition supply, offensive equipment, etc., can solve the problems of affecting flexibility, long loading time, and increasing the load of the whole vehicle, so as to achieve strong safety and reliability, shorten loading time, and improve The effect of loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

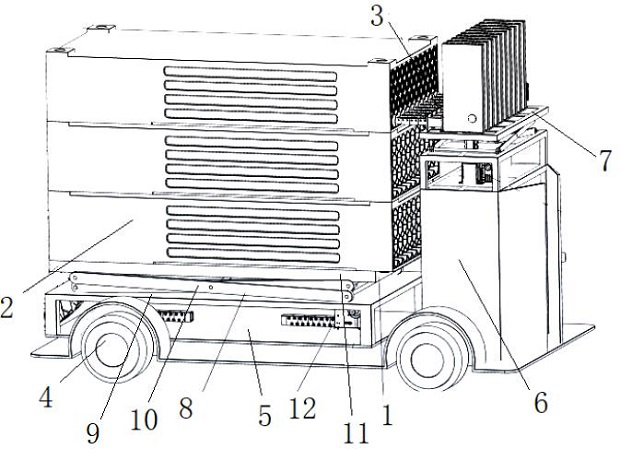

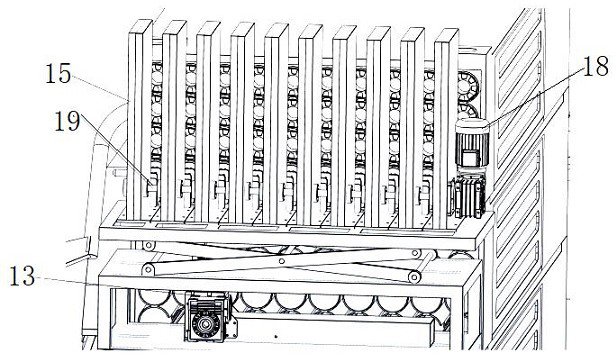

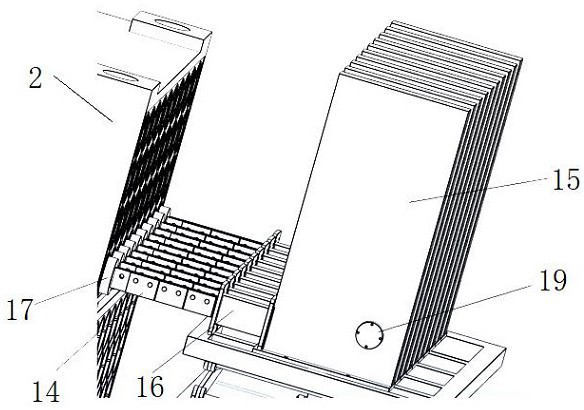

[0032] see Figure 1 to Figure 3 , The present invention relates to a rocket launcher rapid loading system, which is mainly composed of a loading vehicle 1, a loading box 2 and a pushing mechanism 3.

[0033] The loading vehicle 1 is located at the rear side of the rocket carrier vehicle. The bottom of the loading vehicle 1 is provided with wheels 4, which move the loading vehicle 1 through the wheels 4, and the wheels 4 are equipped with locking mechanisms. When the loading vehicle 1 is positioned The trolley can be locked with a locking mechanism to prevent it from moving. The front end of the top of the loading trolley 1 is a platform 5, on which a filling box lifting mechanism 8 is fixed, and the top and rear end of the filling trolley 1 is provided with a box body 6. Various control electrical appliances are placed inside the box body 6 to control the transmission system. The top of the box body 6 is a holding platform 7, and the pushing mechanism 3 is placed on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com