Construction method for high-pressure jet grouting based on slurry return conductivity data

A technology of high-pressure rotary spraying and construction method, which is applied in the direction of foundation structure engineering, foundation structure test, sheet pile wall, etc., and can solve the problems of unable to dynamically monitor the pile diameter, difficult to take remedial measures, unable to make up for material waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

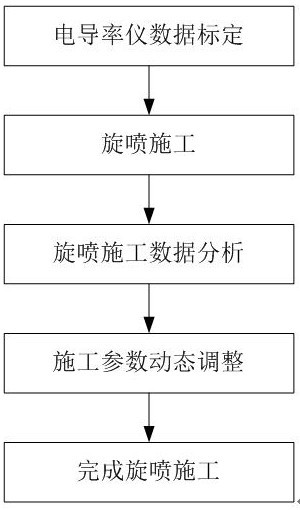

[0033] Such as figure 1 As shown, when the construction is carried out on the site where the standard penetration number N is 20, the following technical scheme is adopted.

[0034] A construction method for high-pressure rotary spraying based on the conductivity data of returned slurry, based on a high-pressure rotary spray test system, the high-pressure rotary spray test system includes a conductivity meter, a return slurry flow meter, a rotary jet drill, a pilot hole drill, and a high-pressure mud Pumps, air compressors, information platforms; conductivity meters, return slurry flow meters, rotary jet drilling rigs, pilot hole drilling rigs, high-pressure mud pumps, air compressors and other equipment are connected to the information platform through wires or untrusted signals. The relevant parameters are displayed and stored on the information platform. The specific construction method is as follows:

[0035] Step 1: Conductivity meter data calibration;

[0036] Mix spec...

Embodiment 2

[0056] Such as figure 1 As shown, when the standard penetration number N is 40, the following technical scheme is adopted for construction.

[0057] A construction method for high-pressure jet spraying based on the conductivity data of returned slurry, characterized in that it is based on a high-pressure jet spray test system, and the high-pressure jet spray test system includes a conductivity meter, a returned slurry flowmeter, a jet jet drill, and a pilot hole Drilling rigs, high-pressure mud pumps, air compressors, and information platforms; conductivity meters, slurry return flow meters, rotary jet drilling rigs, pilot hole drilling rigs, high-pressure mud pumps, air compressors, and other equipment communicate with information platforms through wires or untrusted signals The relevant parameters of the above equipment are displayed and stored on the information platform. The specific construction method is as follows:

[0058] Step 1: Conductivity meter data calibration; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com