High-braking-performance truck wheel set and design method thereof

A kind of freight wheel and performance technology, which is applied in the direction of wheels, wheels characterized by track running parts, and wheel-axle combinations, etc., can solve the complex and unreasonable structure of the wheelset end, the low qualification rate of wheelset assembly, and the impact on the service life of the wheelset. and other problems, to achieve the effect of improving axial movement, small axial displacement and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

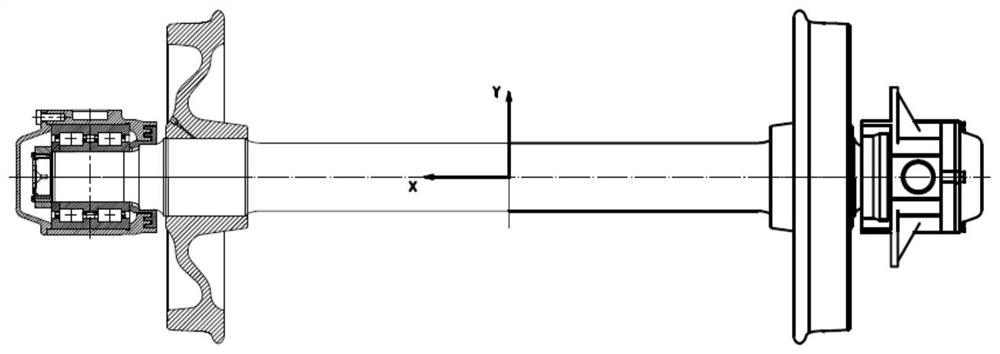

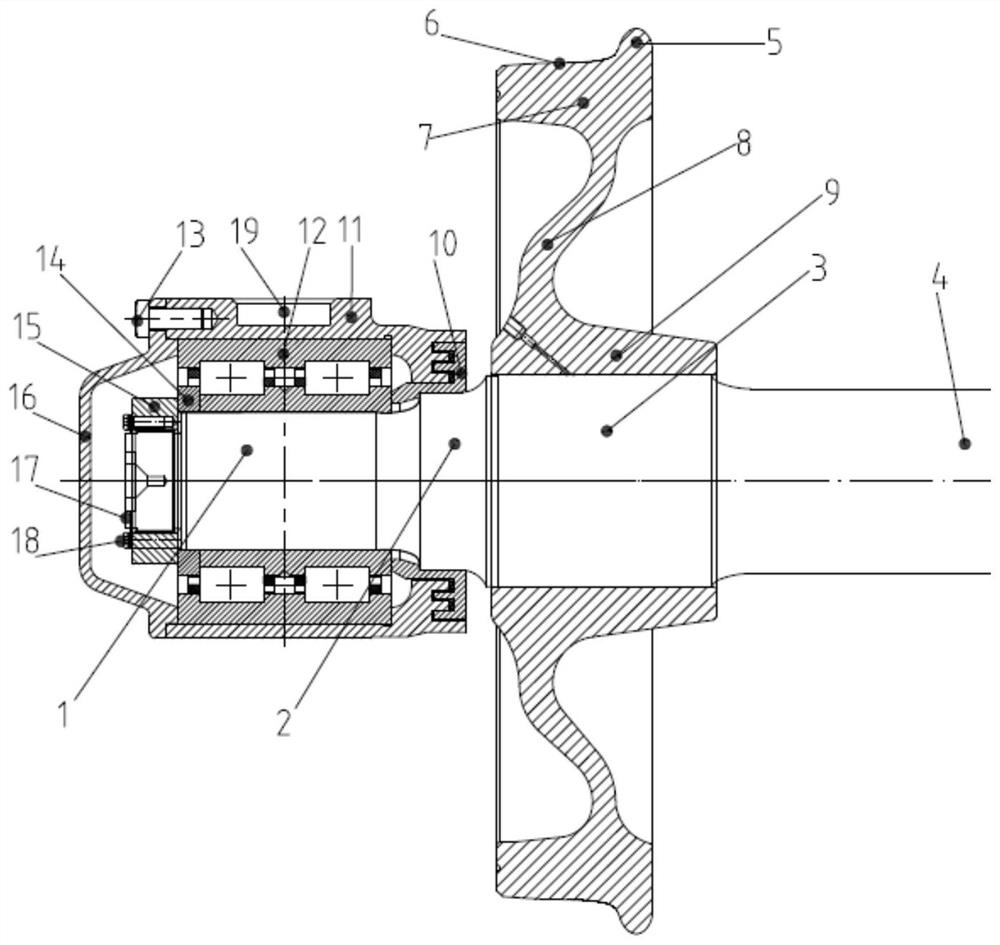

[0043]The high-braking performance freight wheel set includes an axle, a wheel, and an axle box. The axle is a symmetrical cylindrical structure, and is mainly divided into four parts: a journal portion 23, a dustproof seat 24, a wheel seat portion 26, and an axle body portion 27; The wheel is composed of rim 5, tread 6, rim 7, spoke plate 8 and hub 9; the axle and wheel are connected through interference fit, and the left and right ends of the axle are connected with the axle box structure, which is composed of labyrinth rings, bearings, Bearing retaining ring, lock nut, lock washer, lock bolt, axle box, end cover and end cover bolt 13, etc., the axle box structure is provided with a cylindrical groove connected with the bogie damping spring.

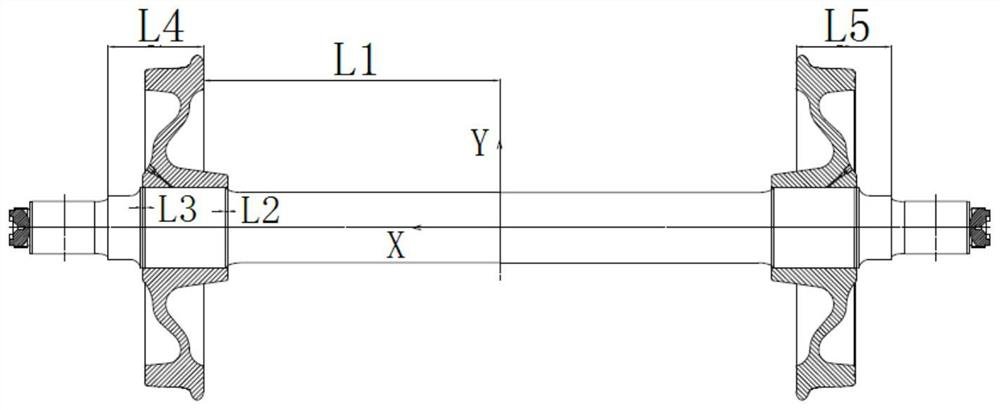

[0044] The axle includes keyway, bearing positioning thread, journal, dustproof seat, wheel seat and axle body, each structure is symmetrically distributed along the vertical center line of the axle, the keyway and bearing positioning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com