Locking mechanism

A locking mechanism and connecting rod technology, applied in structural parts, electric vehicles, electrical components, etc., can solve the problems of poor compatibility of the height error of the pressing force direction, small driving force amplification effect, and small driving force amplification ratio. Achieve the effect of small space path requirements, improved stability, and compact locking mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] With the development of new energy technology, the application of new energy batteries is becoming more and more extensive. However, the existing new energy batteries are faced with the problems of short cruising range and slow charging, so a battery replacement technology is proposed to solve the above problems through fast battery replacement. In order to improve the efficiency of battery replacement and maintain the stability of the battery pack, a locking mechanism is generally provided between the battery pack and the vehicle frame to fix the battery pack.

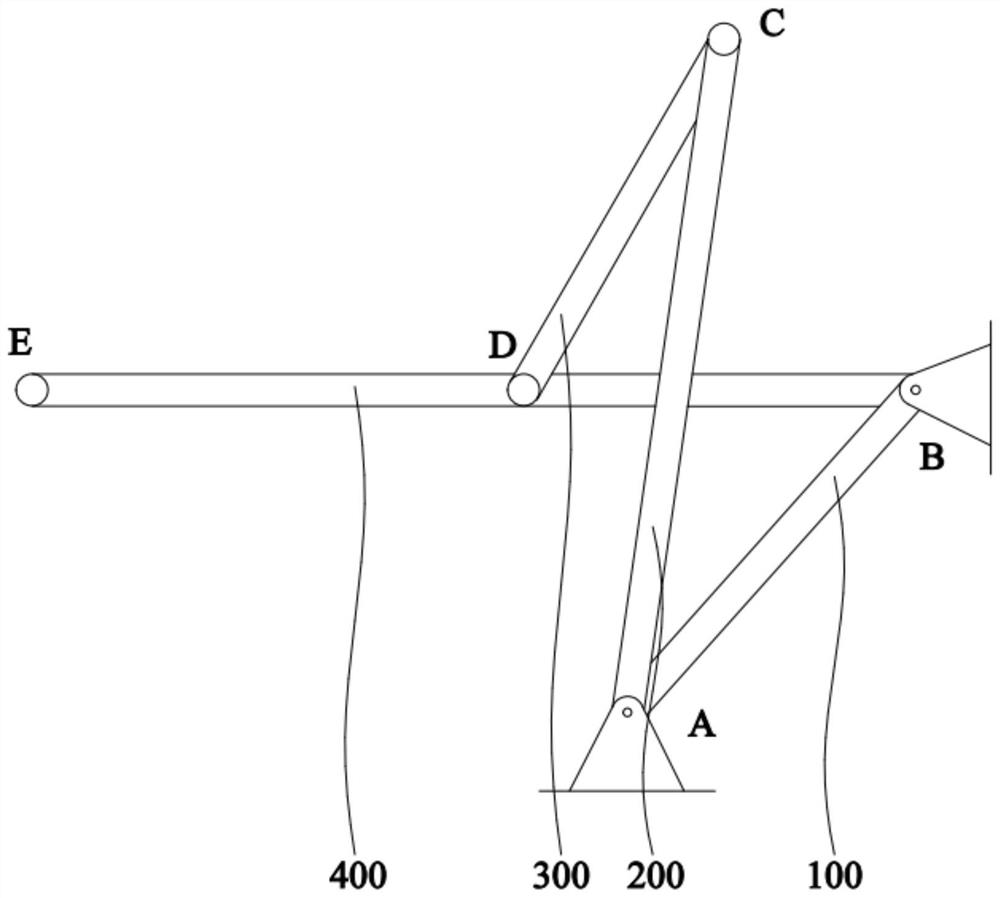

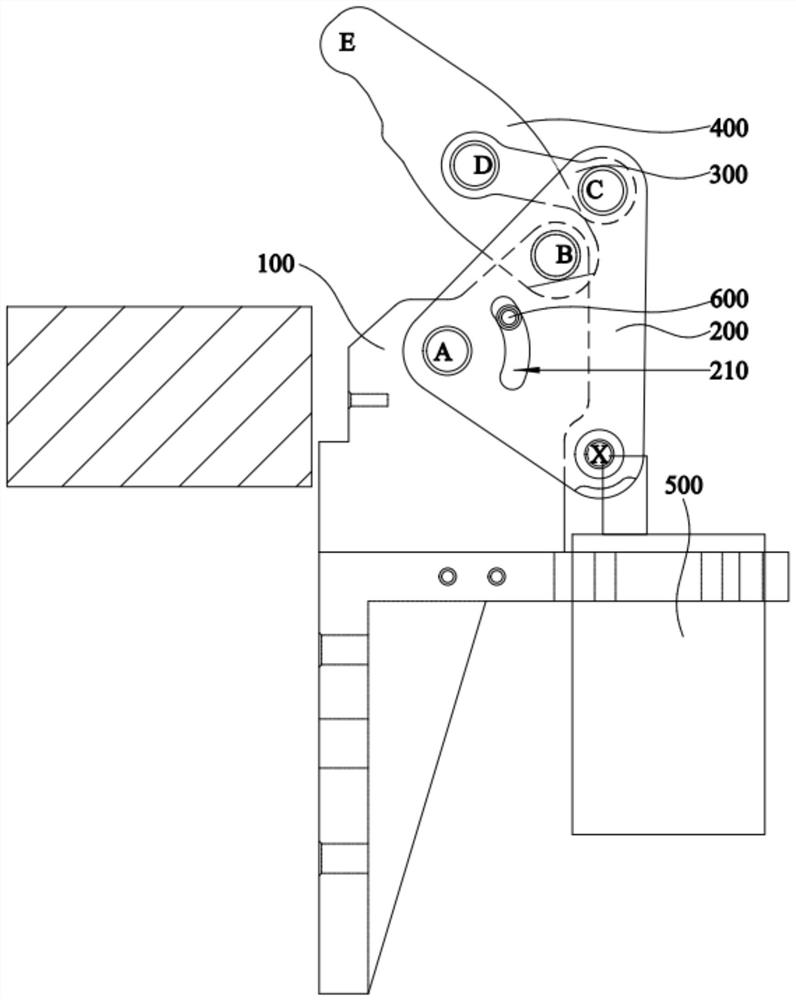

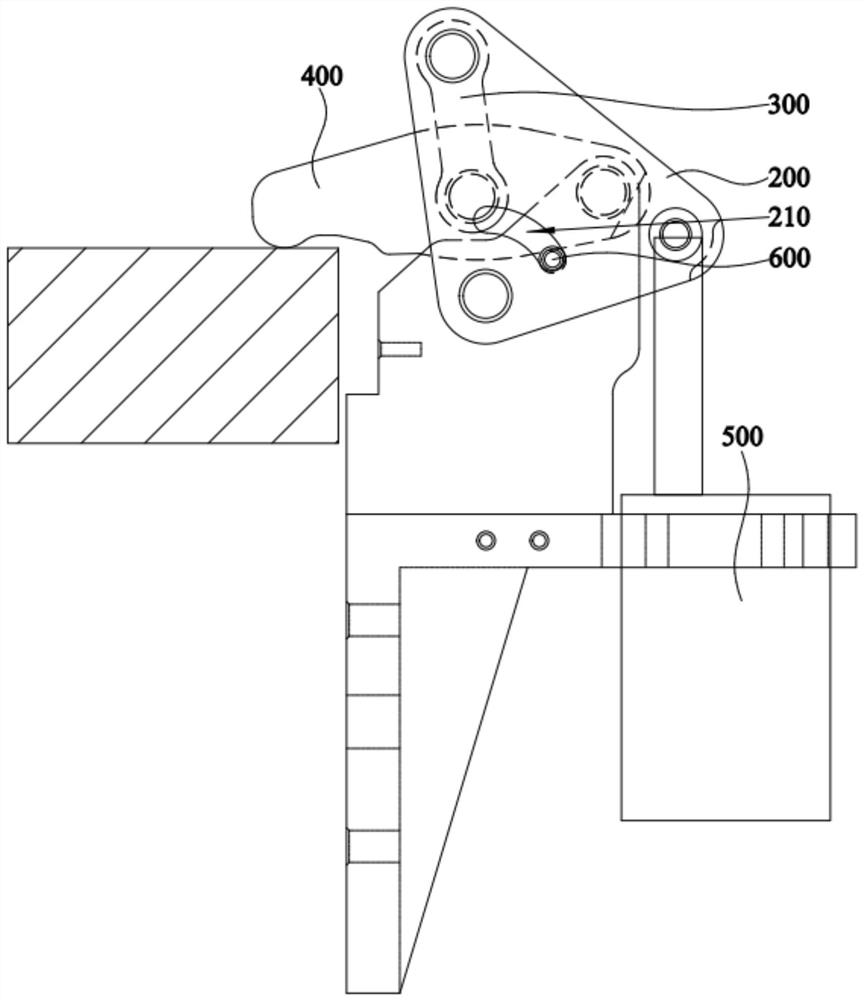

[0042] like figure 1 and figure 2 As shown, the present embodiment provides a locking mechanism, which includes a first link 100 , a second link 200 , a third link 300 , a fourth link 400 and a driving member 500 . The first connecting rod 100 is fixed, the second connecting rod 200 and the first connecting rod 100 are hinged at the pivot point A, the third connecting rod 300 and the second connecting rod 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com