Laser cutting machine facilitating waste treatment

A laser cutting machine and waste material technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficult collection of smoke and slag, injury to staff, waste generation, etc., to ensure work effect and protect the environment , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] Such as Figure 1-12 As shown, this application provides:

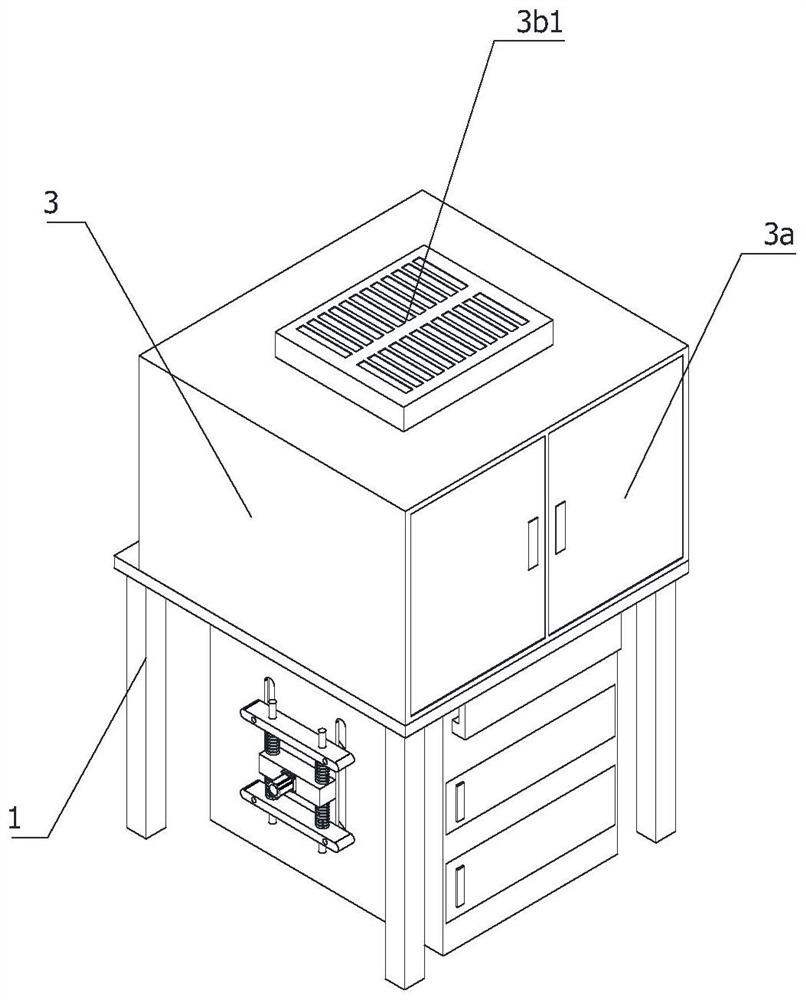

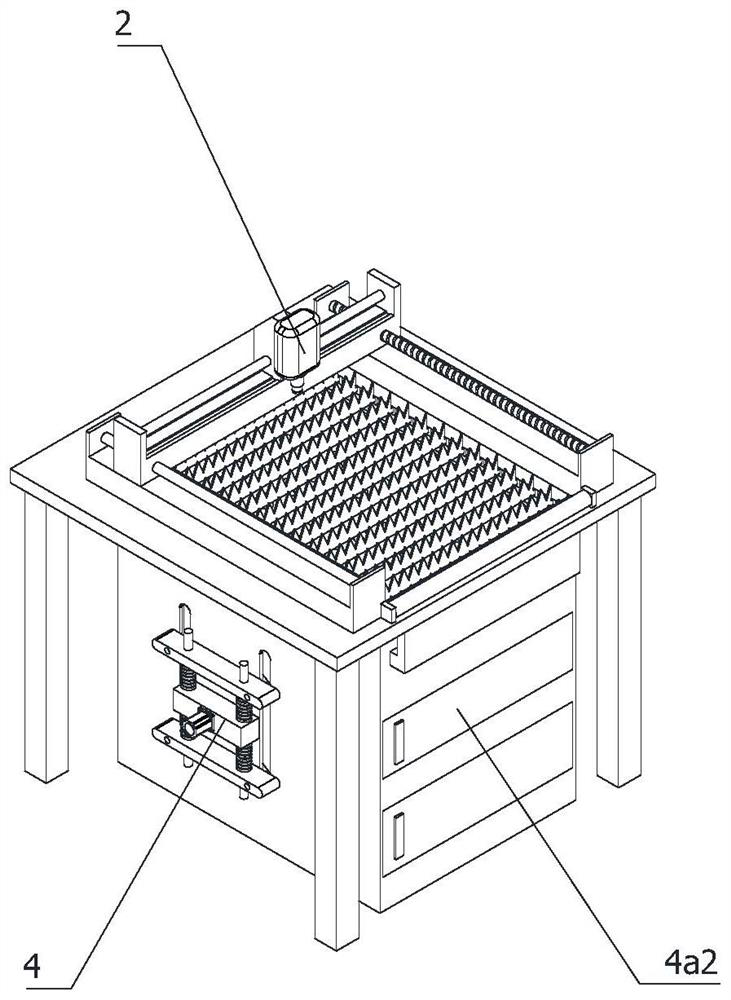

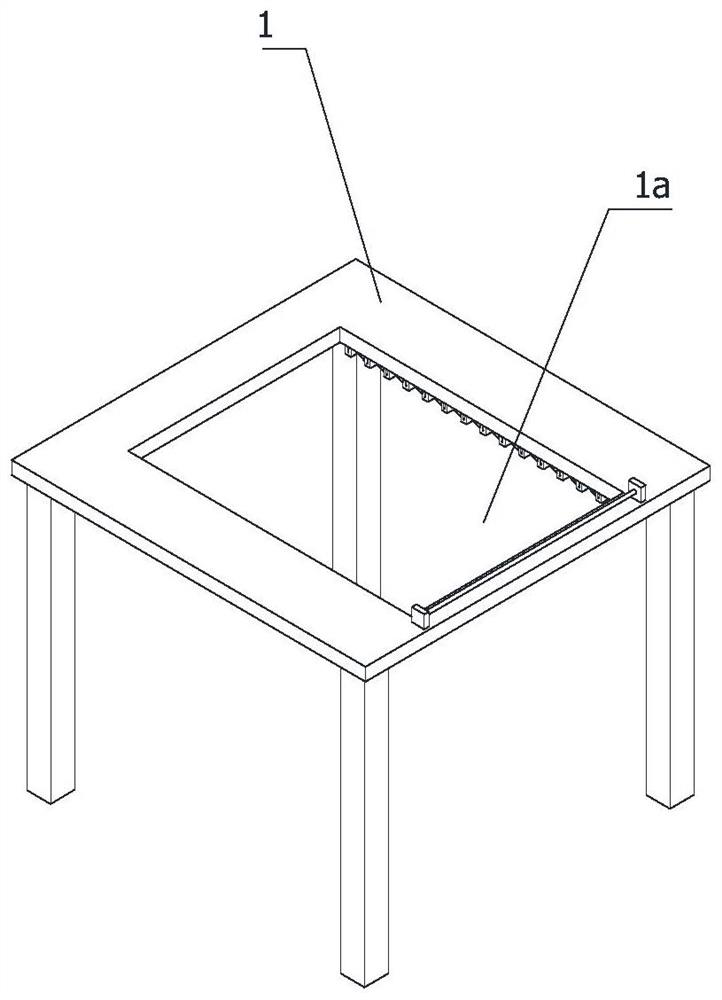

[0046] A kind of laser cutting machine that is convenient to process waste, comprises workbench 1 and cutting assembly 2, and described cutting assembly 2 is positioned at the top of workbench 1, and the center of workbench 1 is provided with blanking groove 1a, and workbench 1 is provided with The sealing cover 3, the fresh air assembly 3b, the collection mechanism 4 for screening waste materials and finished products, and the adjustment assembly 5 for adjusting the size of the blanking chute 1a, the sealing cover 3 is located above the workbench 1, and the fresh air assembly 3b is located at the sealing On the cover 3, the collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com