Intelligent re-checking type lithium battery surface defect detection device

A defect detection and lithium battery technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low intelligence and integration, automation, low integration, and increased production costs , to achieve the effect of facilitating lifting control and horizontal movement control, improving production efficiency and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

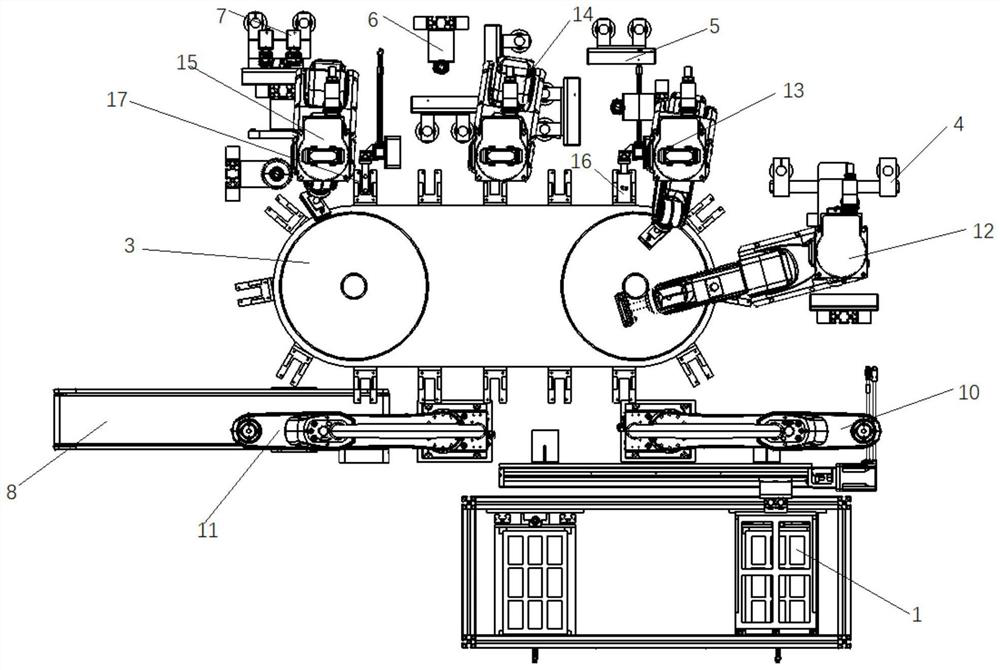

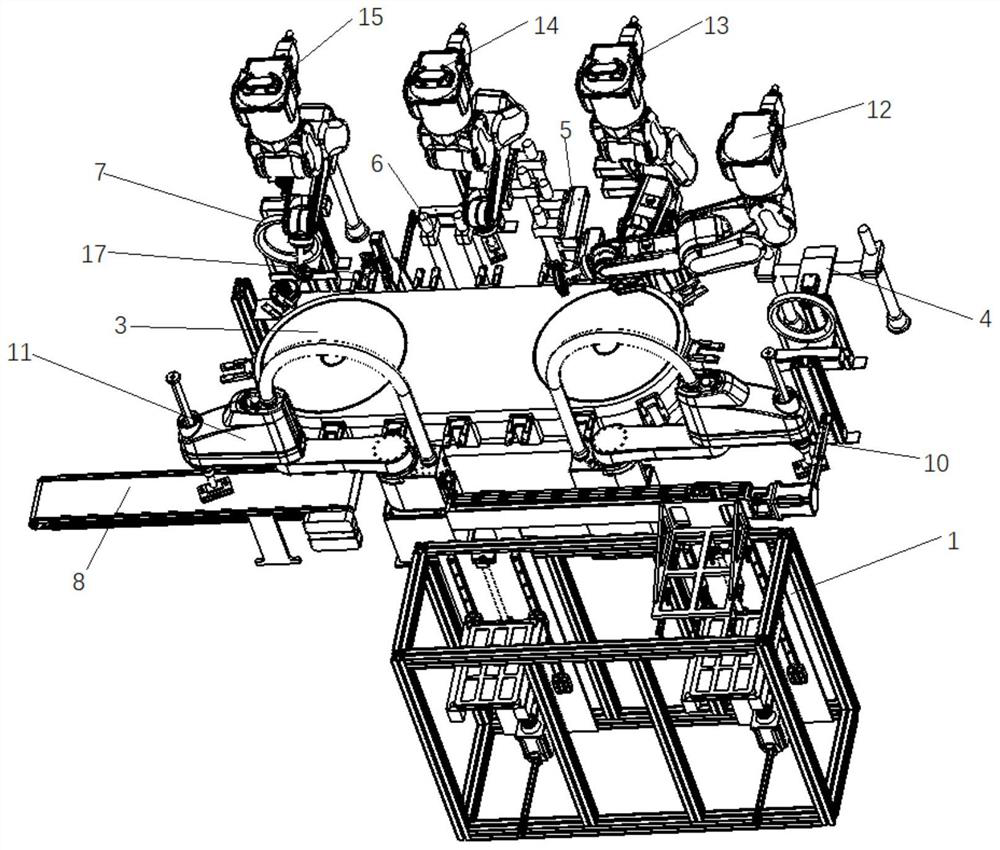

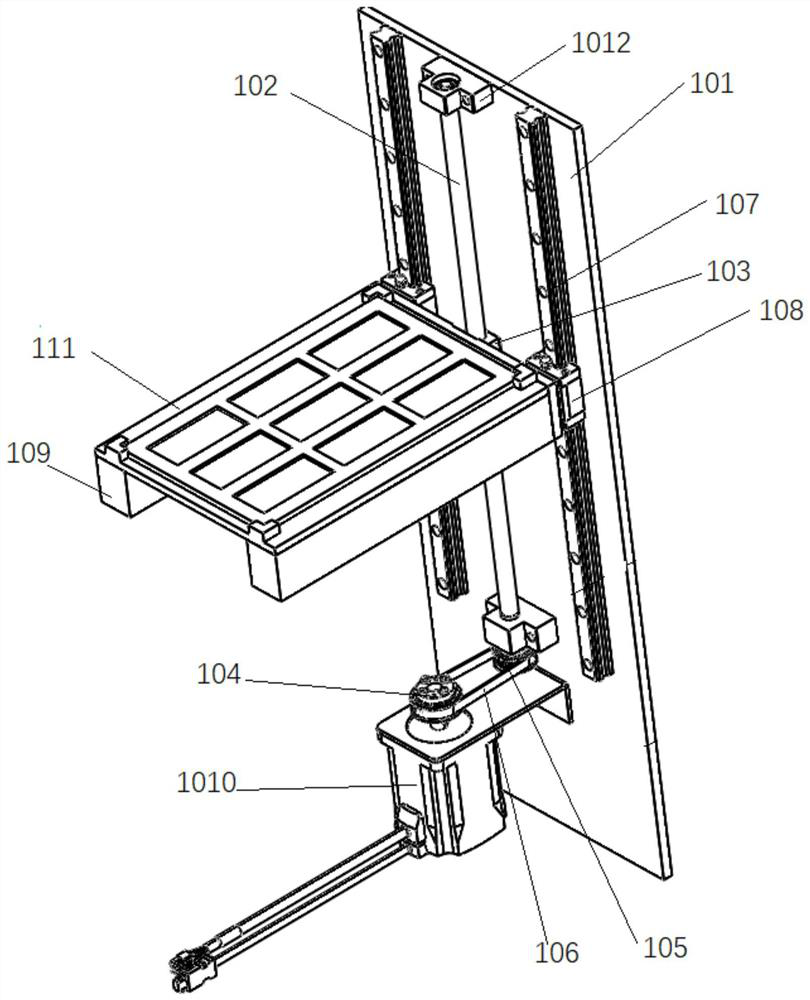

[0035] Such as Figure 1 to Figure 15 As shown, an intelligent double-check type lithium battery surface defect detection device includes a rotating device 3, a side image capturing device 4, a front image capturing device 5, a reverse image capturing device 6, a two-way image capturing device 7, an upper The material manipulator 10 and the blanking manipulator 11, the material loading manipulator 10, the side image capturing device 4, the front phase capturing device 5, the reverse phase capturing device 6, the two-way phase capturing device 7 and the blanking device 11 rotate along the The direction of rotation of the device 3 is arranged at intervals successively, and one side of the side face-taking photographing device 4 is provided with a first transfer manipulator 12, and one side of the front face-taking photographing device 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com