Full-automatic after-needle pasting sheet taking machine

A fully automatic, rotary-driven technology, applied in the fields of medical science, bandages, sending objects, etc., can solve the problems of cumbersome operation of changing rolls, easy to contaminate needles and sticking coils, and it is difficult to ensure aseptic operation during the operation process. Aseptic operation, fast and convenient replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

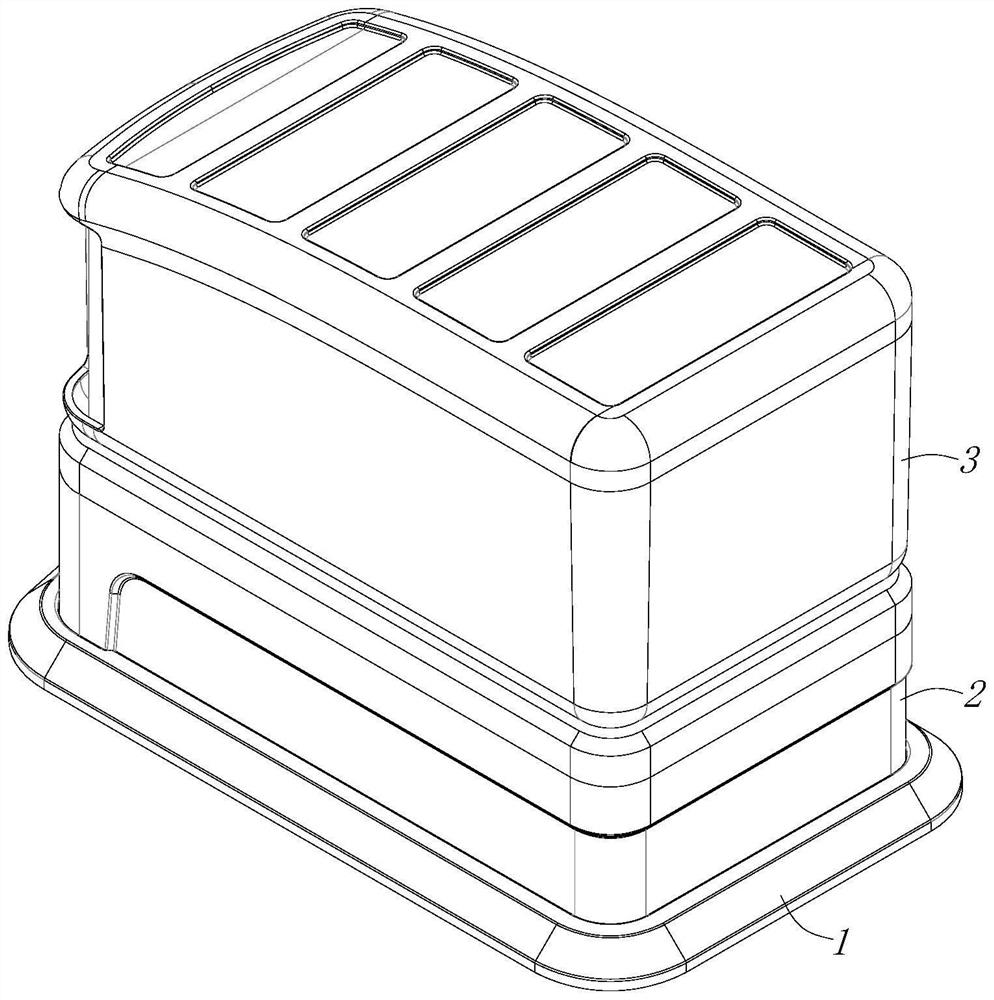

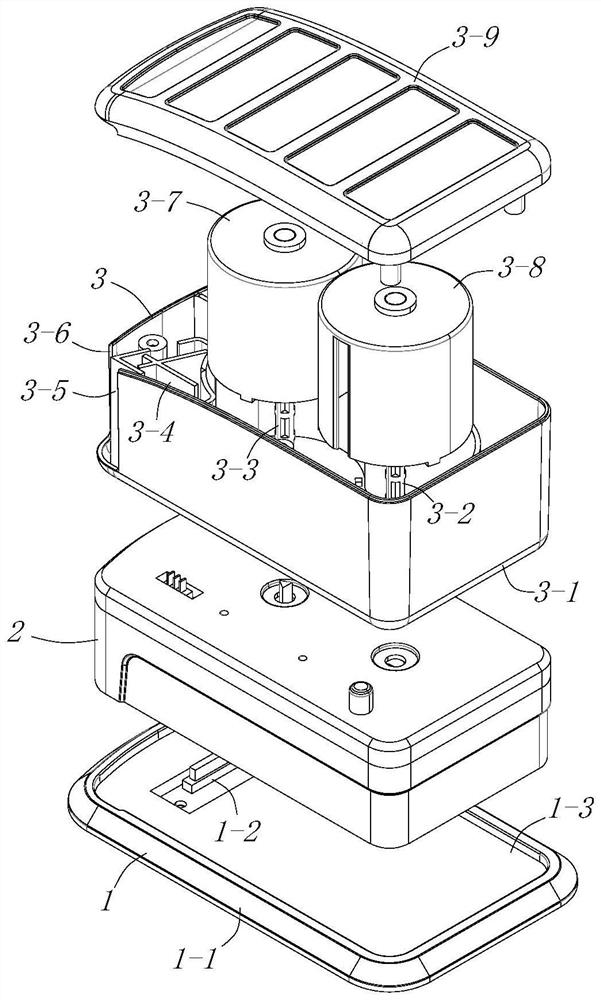

[0023] See figure 1 , the automatic post-needle post-attaching and taking-off machine of the present invention includes a base device 1 connected to a power source, and a rotating drive device 2 electrically connected to the base device 1 is plugged in.

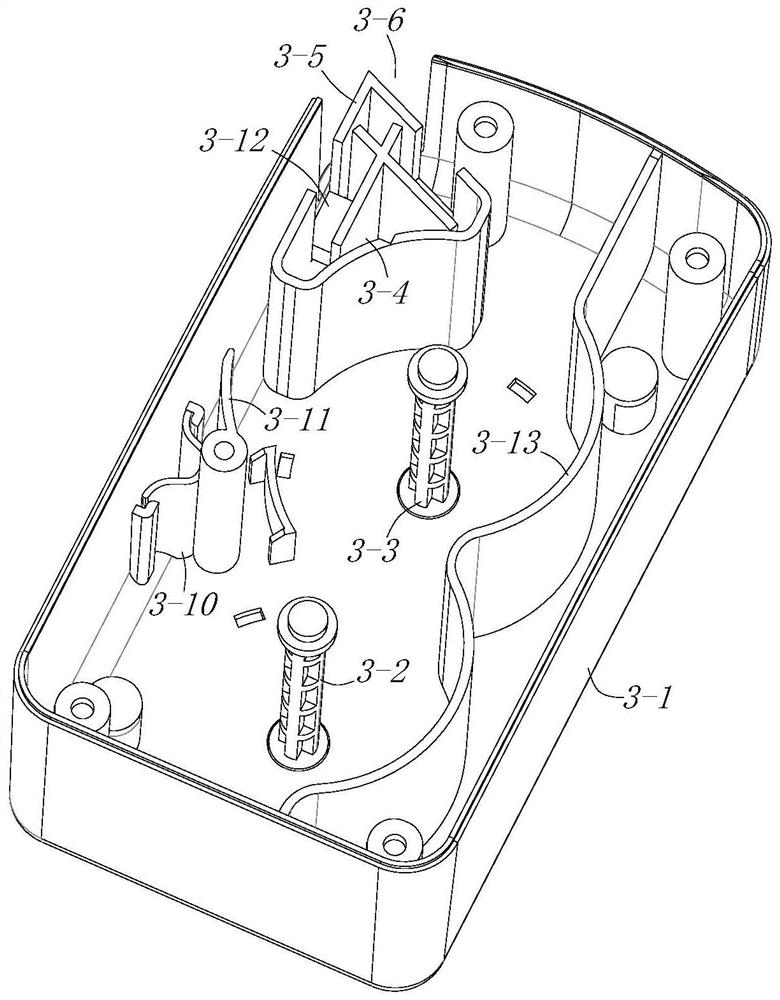

[0024] see further figure 2 , in this embodiment, the base device 1 includes a socket base 1-1, a rectangular socket slot 1-3 is arranged on the top of the socket base 1-1, and the lower part of the rotating drive device 2 is inserted in the socket Inside slots 1-3. The base device 1 also includes a first connection terminal 1-2 installed on the socket base 1-1 to be electrically connected to a power source, and the rotation driving device 2 is electrically connected to the base device 1 through the first connection terminal 1-2. Further, the first conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com