Automatic cover opening and closing assembly convenient to operate

A technology with automatic opening and closing and convenient operation. It is applied in the direction of closing, packaging, transportation and packaging, etc. It can solve the problems of container overturning, waste, easy spillage and outflow of products in the inner cavity of the container, and achieve good sealing and large take-out effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

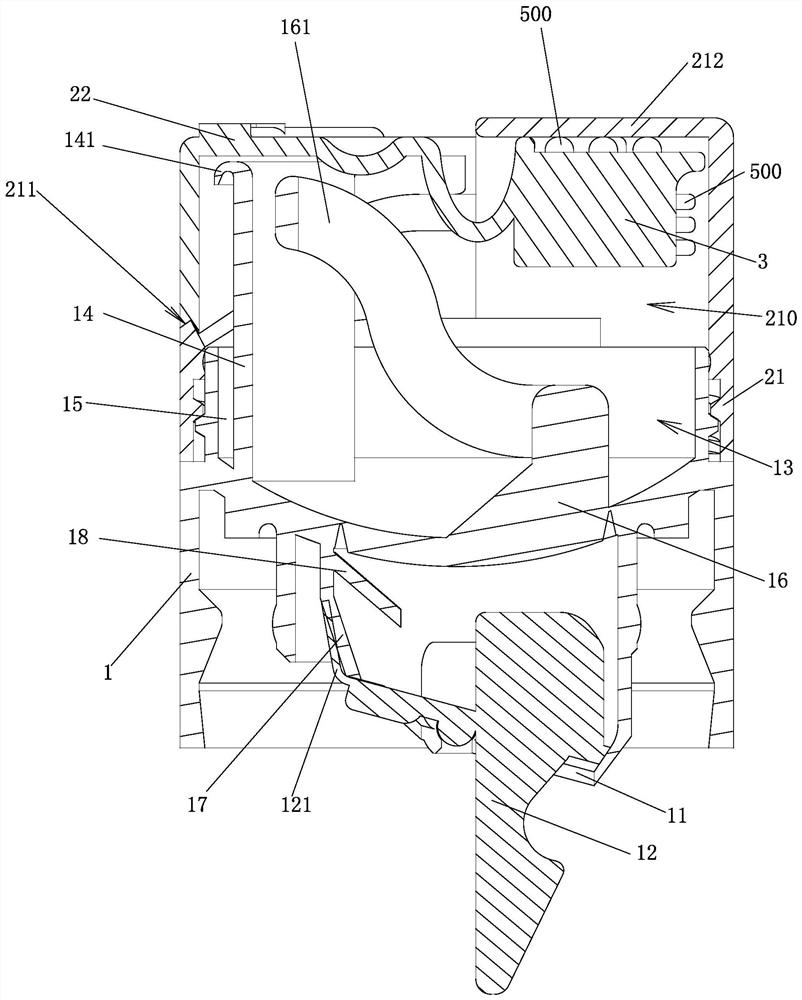

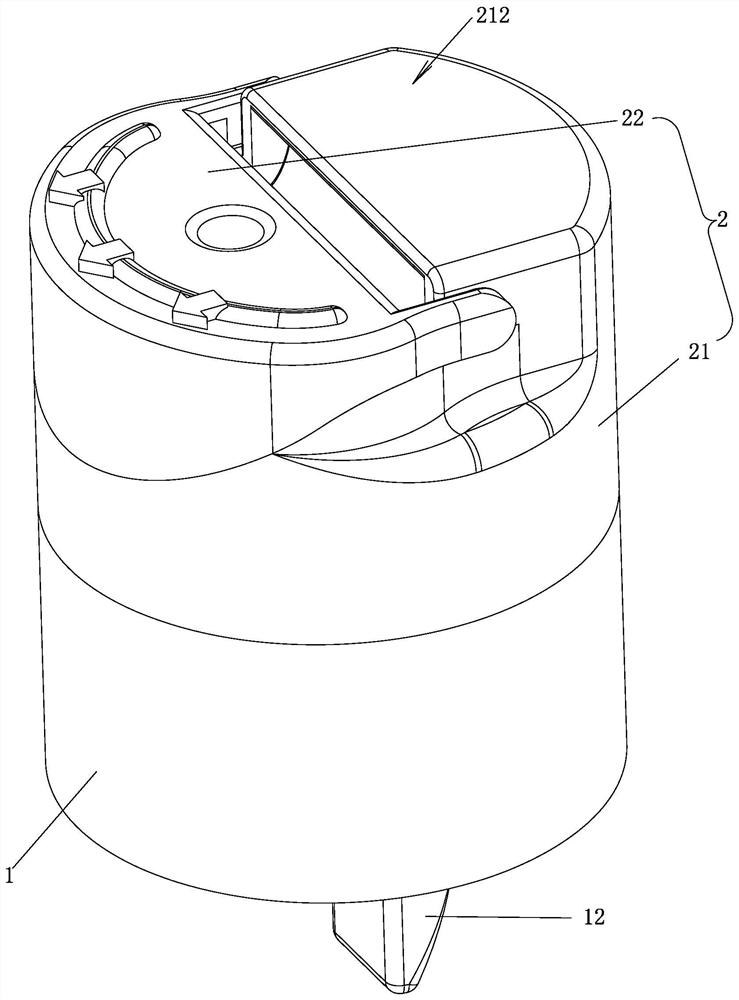

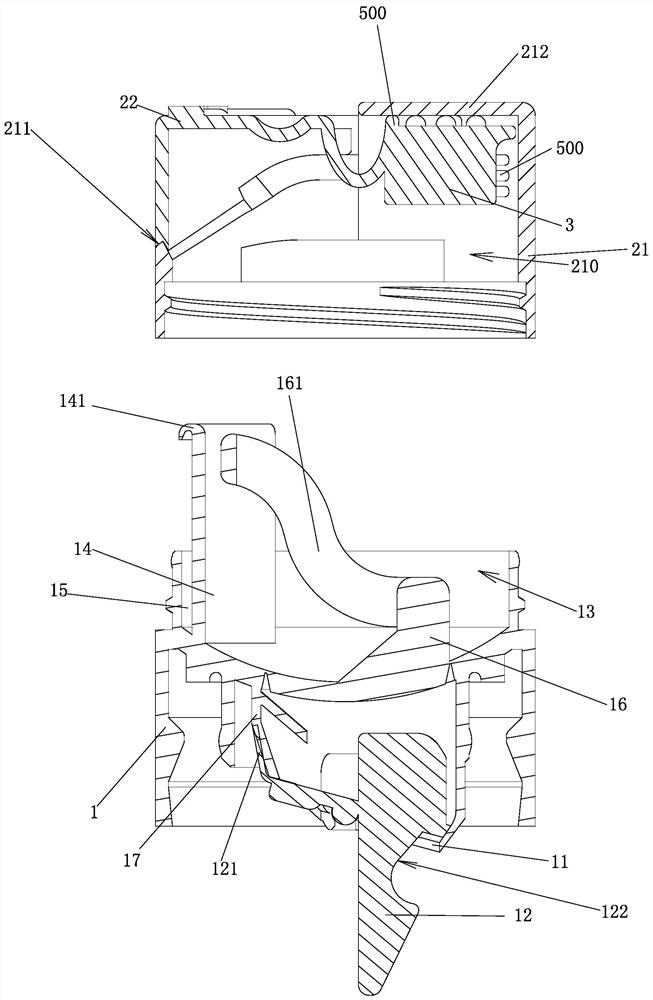

[0041] Embodiment 1: as Figures 1 to 9As shown, the present invention provides an easy-to-operate automatic opening and closing lid assembly, which includes a housing 1 and a lid 2 connected to the housing 1, and the housing 1 is provided with a lower lid that can be connected to the mouth of the container. Mouth 11, the cover 2 includes a middle cover 21 detachably connected to the housing 1, and the middle cover 21 is provided with an upper mouth 211 communicating with the lower mouth 11 and used for liquid outlet The middle cover 21 is provided with an upper cover 22 that can open or close the upper mouth 211 when it is rotated relative to it, and the housing 1 is provided with a closure 12 that can open or close the lower mouth 11 when it is rotated relative to it. , the casing 1 is also provided with a seal 16 that can communicate with the upper mouth 211 and the lower mouth 11 after being torn. When in use, it is necessary to remove the middle cover 21 from the casing ...

Embodiment 2

[0053] Embodiment 2: as Figure 10 As shown, the difference between the present embodiment and the first embodiment is that a rough surface 400 is provided on the side of the gravity block 3 opposite to the inner wall of the accommodating chamber 210 . By setting the rough surface 400 on the inner wall of the gravity block 3 or the accommodation cavity 210, it can be avoided that when the sticky product sticks between the gravity block 3 and the inner wall of the accommodation cavity 210, the gravity block 3 cannot be returned. If the rough surface 400 is provided, Then the liquid cannot cling to the outer wall of the gravity block 3 and the inner wall of the accommodating cavity 210 , thereby affecting the rotation of the gravity block 3 relative to the middle cover 21 .

Embodiment 3

[0054] Embodiment 3: as Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the middle cover 21 is reversibly connected to the housing 1 through a folding bar or a pivot pin. The body 1 is turned over, and then the closure 12 is removed. By observing the direction of the upper mouth 211 or the liquid baffle 18, the direction of pouring liquid can be judged, and the liquid will not be poured in reverse and poured on the upper cover 22 to prevent pollution. Cover 22, causing hygienic problems, and compared with the past, directly inserting fingers into the bottle cap to take out the seal, now the middle cover 21 is turned over relative to the shell 1, and then the seal is removed, and the middle cover 21 is relative to the shell 1 After turning over, there is a larger take-out space, and fingers will not come into contact with the upper cover 22, which will pollute the upper cover 22 and cause hygienic problems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com