High-speed emulsifying device applied to polyurethane coating

A polyurethane coating and emulsifying device technology, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inconvenient disassembly and cleaning, reduced emulsifying effect, material splashing, etc., and achieves easy installation, disassembly, and use. The effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

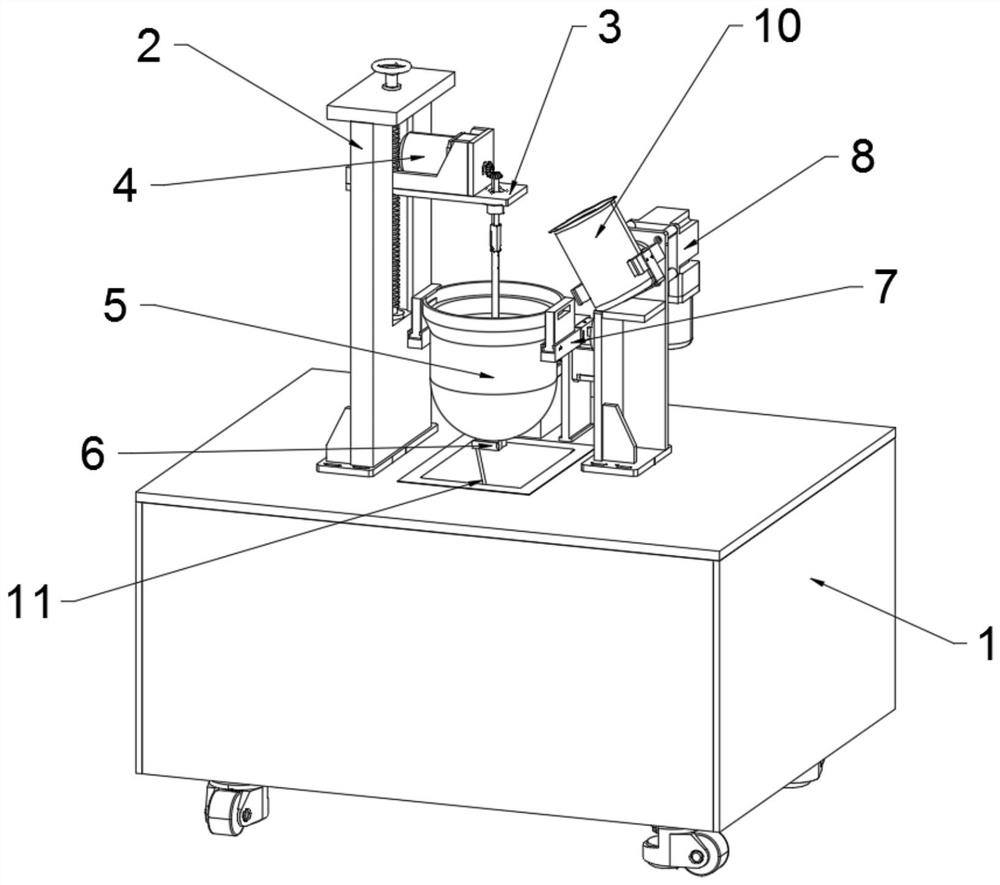

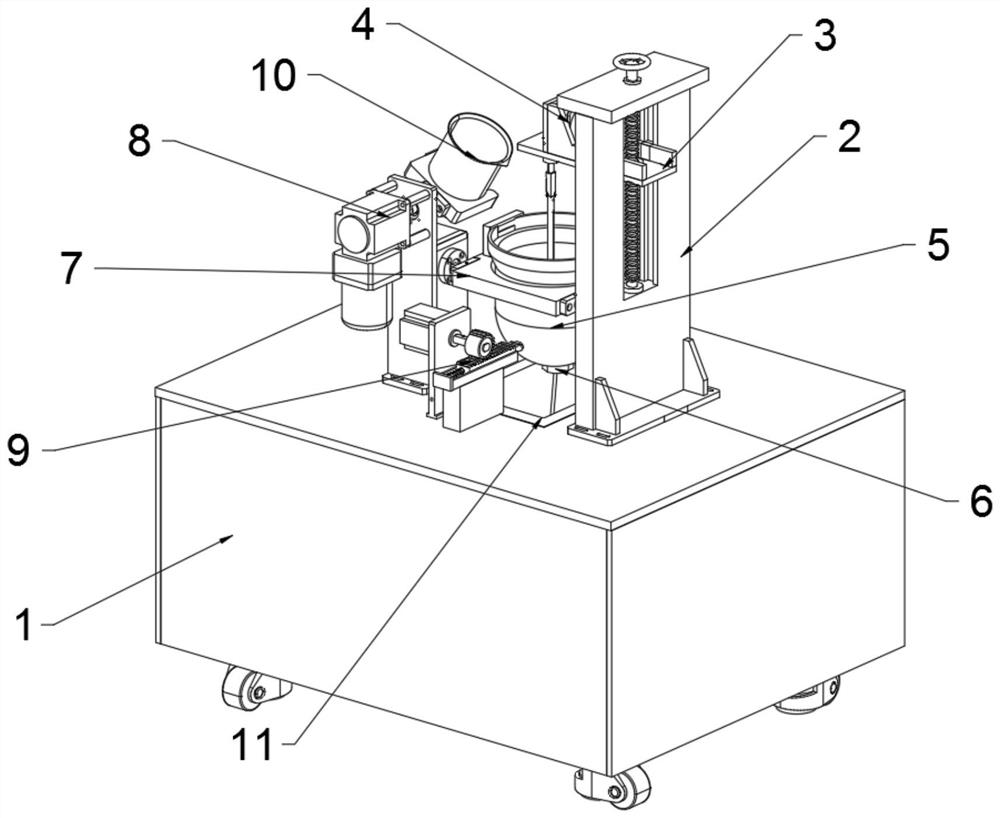

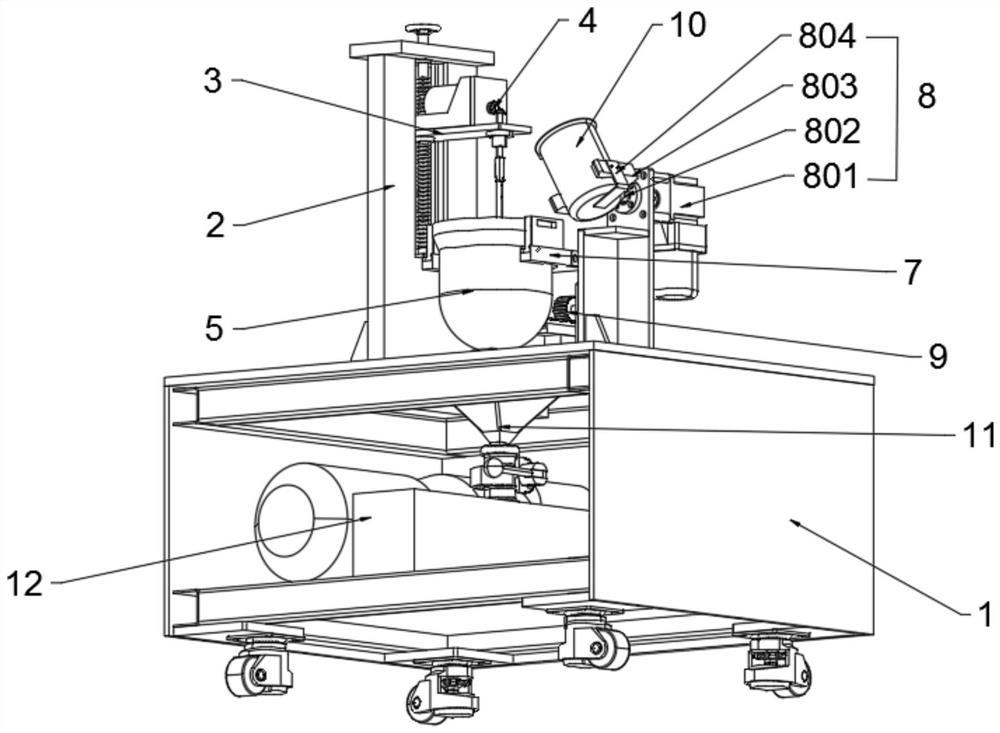

[0033] as attached figure 1 To attach Figure 7 Shown:

[0034] The invention provides a high-speed emulsification device applied to polyurethane coatings, comprising a base 1, the base 1 is a rectangular through-cavity structure, and an emulsification tank 12 is arranged in the cavity of the base 1; a collection tank 11 is arranged in the middle of the top of the base 1, and The collection tank 11 communicates with the emulsification tank 12; the top of the base 1 is provided with an adjustment frame 2, and the adjustment frame 2 is arranged on the left side of the collection tank 11; 2 There is a first chute 201 in the middle position, and a screw rod 202 is arranged in the first chute 201, and a hand wheel 203 is arranged on the top of the screw rod 202, and the screw rod 202 is rotatably connected with the adjustment frame 2 through a bearing; the top end of the base 1 A fixed frame 13 is provided, and the fixed frame 13 is located on the right side of the collecting tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com