Passenger car front area floor mounting structure and assembling method

An installation structure and front area technology, which is applied in the field of floor installation structure and assembly in the front area of passenger cars, can solve problems such as poor consistency, poor appearance quality, and poor accuracy of the engine compartment, so as to improve the riding environment, tidy overall layout, and noise reduction effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

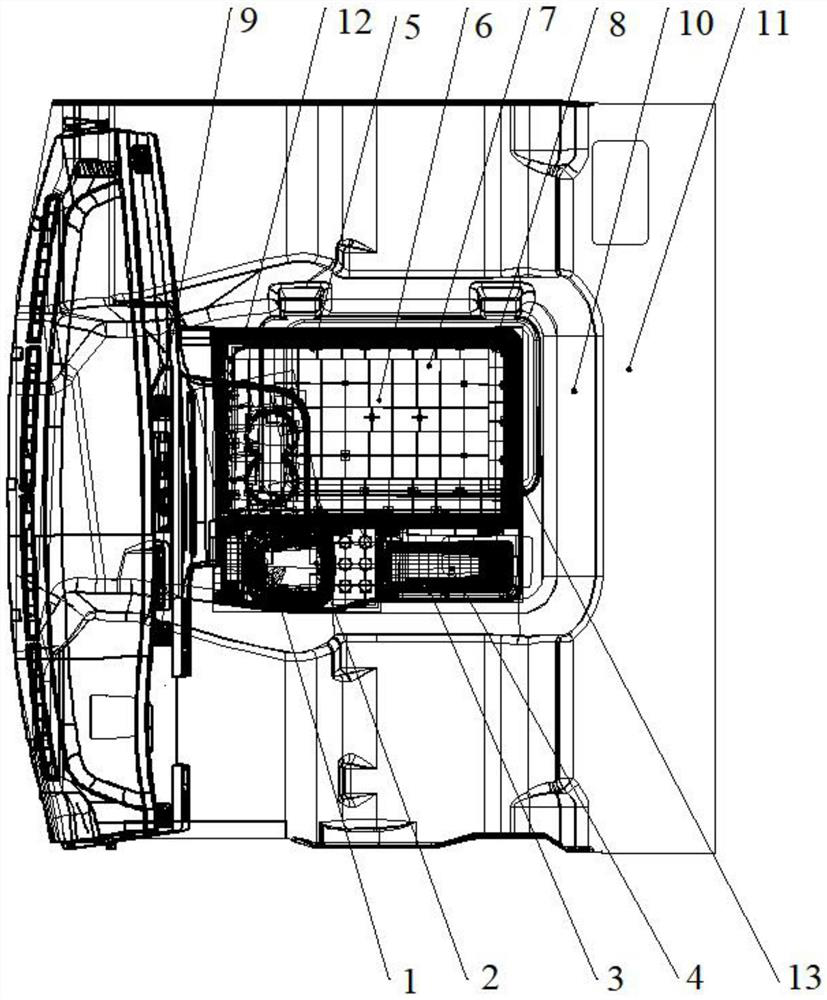

[0032] see figure 1 As shown, the present invention is a floor installation structure in the front area of a passenger car, including a gear shield assembly, a hand brake shield assembly, a hood assembly, an instrument panel sub-panel assembly, a front carpet assembly and an engine compartment assembly; the gear shield assembly It is arranged side by side with the hand brake cover assembly, and they are all located on one side of the hood assembly. The instrument panel sub-panel assembly is arranged in front of the hood assembly, the engine compartment assembly is provided with a hood assembly, the gear guard assembly, the hand Brake guard assembly, hood assembly, instrument panel sub-panel assembly and engine compartment assembly are located above the front carpet assembly;

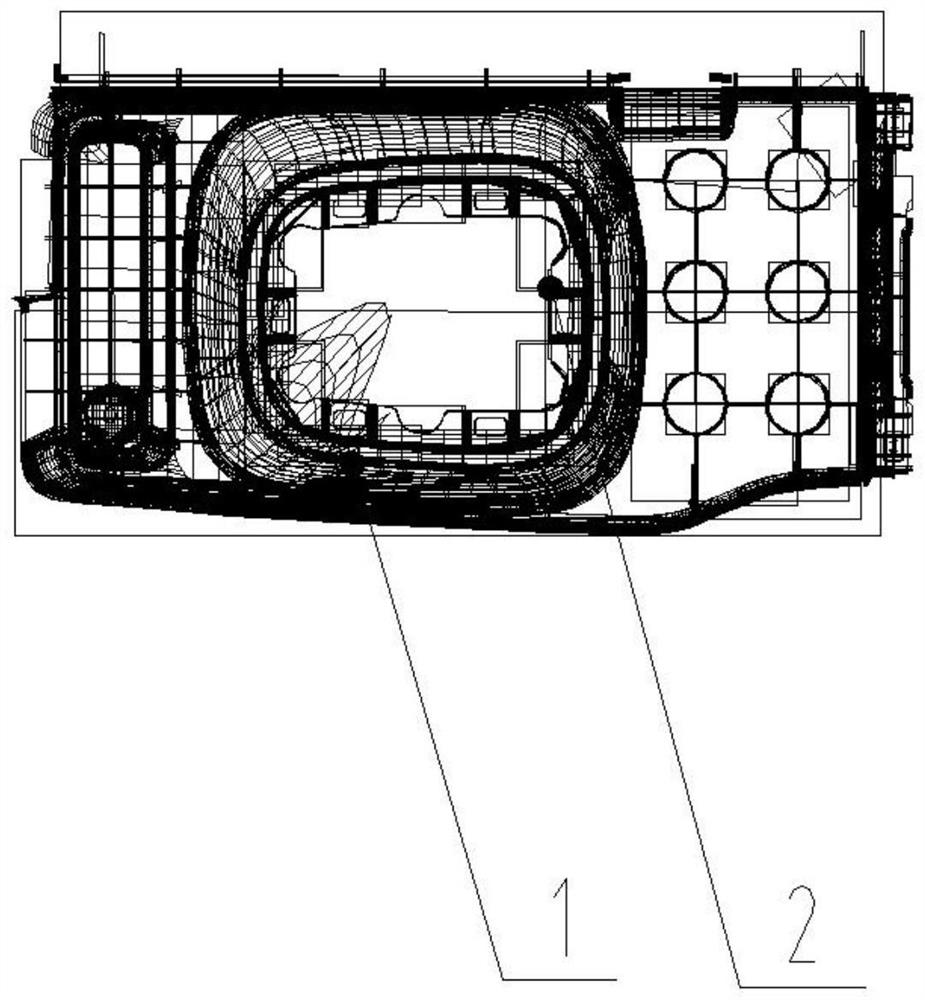

[0033] see figure 2 As shown, the gear cover assembly includes a gear cover base 1 and a gear cover 2; the gear cover base 1 is an independent base structure and is arranged on the engine compartment...

Embodiment 2

[0048] A passenger car front area floor installation structure, the assembly method of the passenger car front area floor installation structure specifically includes the following steps:

[0049] Step 1: Install the engine compartment sheet metal 12 of the engine compartment assembly on the engine compartment opening by means of interference fit;

[0050] Step 2: Fix the front carpet 10 of the front carpet assembly on the top of the engine compartment sheet metal 12 by gluing, and lay the front area sound insulation and heat insulation board 11 in the car near the engine compartment;

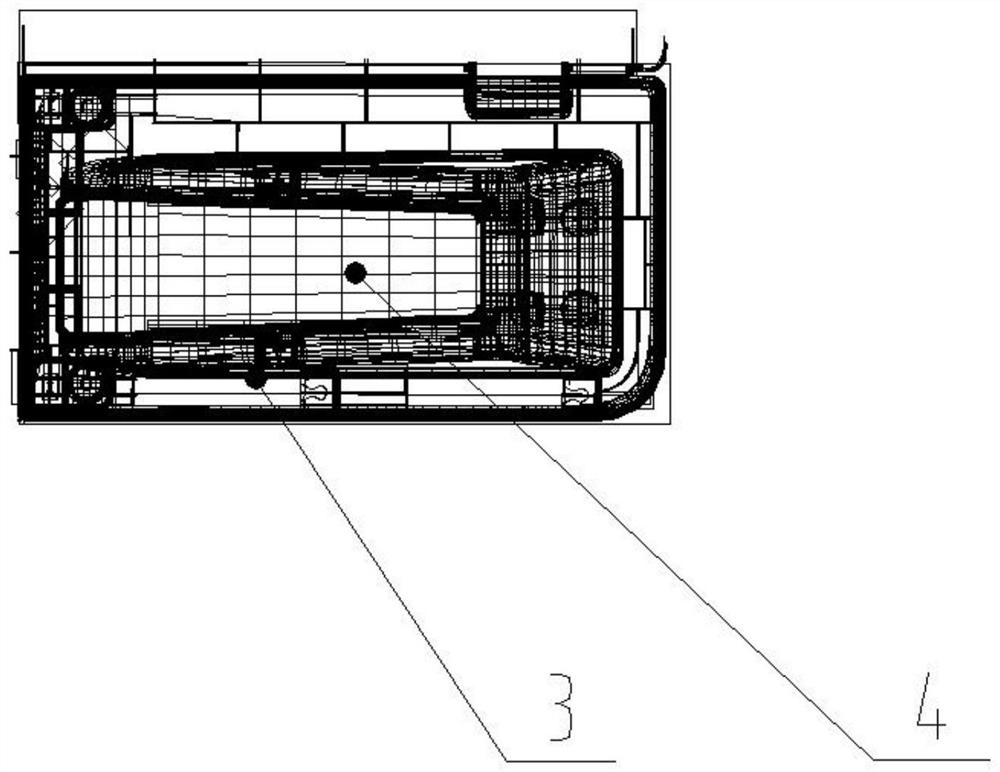

[0051] Step 3: Fix the gear cover base 1 and the gear cover 2 with self-tapping screws to form a gear cover assembly, and install it on the gear;

[0052] Step 4: Fix the hand brake base 3 and the hand brake cover 4 with self-tapping screws to form a hand brake cover assembly, and install it on the hand brake;

[0053] Step 5: Fix the hood cover 5, sound insulation material 6, hood base 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com