Sintering constant-temperature box for manufacturing thermistor

A technology of thermistor and constant temperature box, which is applied in the direction of resistance manufacturing, resistors, resistors with positive temperature coefficient, etc., can solve the problem of affecting the sintering quality of the thermistor green body, and can not improve the sintering of the thermistor green body. Efficiency, cracking of the green body of the thermistor, etc., to achieve the effect of easy promotion, simple structure, and improved sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

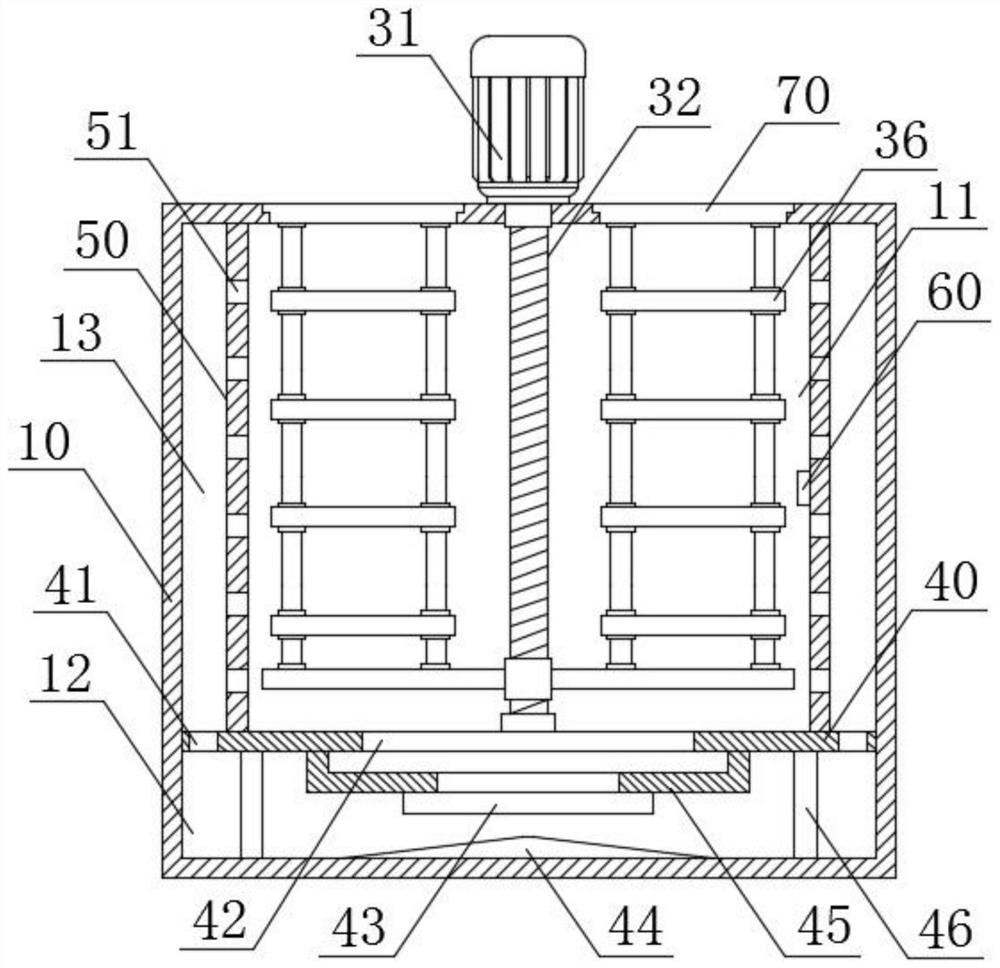

[0036] see Figure 1-6 , The present invention provides a technical solution: a sintered constant temperature box for manufacturing thermistors, comprising: a box body 10 and a lifting mechanism 30 .

[0037] In this embodiment, specifically, the box body 10 is a cylindrical structure.

[0038] Wherein, the inside of the box body 10 is fixedly installed with a horizontal partition 40 and a vertical partition 50, the bottom of the vertical partition 50 is fixedly connected to the top of the horizontal partition 40, and the top of the vertical partition 50 is fixedly connected to the box body. 10, the horizontal partition 40 divides the interior of the box 10 from top to bottom into a sintering chamber 11 and a heating chamber 12, and a circulating air duct is formed between the outer wall of the vertical partition 50 and the inner wall of the box 10 13. The bottom end of the transverse partition 40 is fixedly installed on the fan 43 through the fixing bracket 45, and the botto...

Embodiment 2

[0059] see Figure 1-6 , The present invention provides a technical solution: a sintered constant temperature box for manufacturing thermistors, comprising: a box body 10 and a lifting mechanism 30 .

[0060] In this embodiment, specifically, the top of the box body 10 is provided with a notch for the storage platform 36 to pass through.

[0061] Wherein, the lifting mechanism 30 includes a drive motor 31 whose power output end runs through the box body 10 and is fixedly connected with a threaded screw rod 32, and the outside of the threaded screw rod 32 is slidably installed with a sliding nut 33, and the outside of the sliding nut 33 is fixedly installed with a Lifting plate 34, the top surface of the lifting plate 34 is fixedly equipped with support rods 35, and the support rods 35 are provided with several pieces, and the outside of the support rods 35 is fixedly installed with a storage table 36, and several storage tables 36 are provided.

[0062] Further, the driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com