Induction heating type aerosol forming device and application thereof

An induction heating and aerosol technology, which is applied to tobacco and other fields, can solve the problems of high process difficulty coefficient, easily damaged conductive lines, and many manufacturing process links, and achieve the effects of slow heating, enhanced efficiency, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

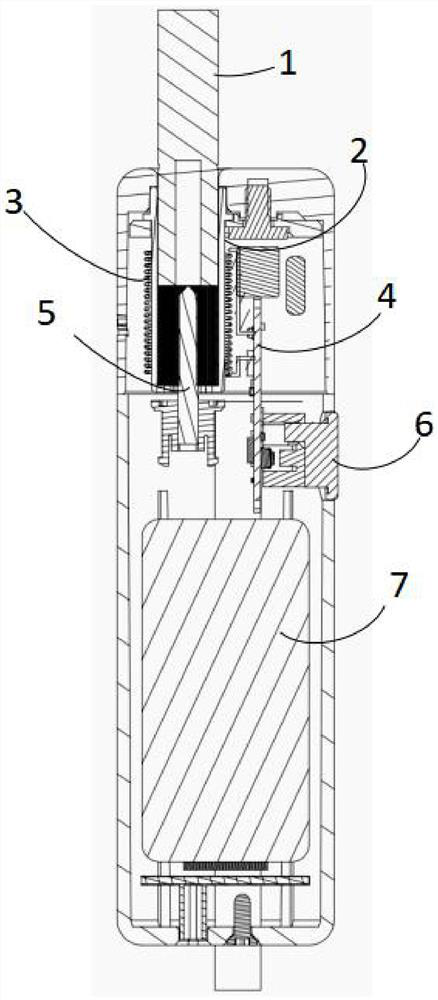

[0059] Such as figure 1 , an electromagnetic induction heating aerosol forming device, the aerosol forming device comprises: a housing. The shell is provided with a heating element 5, a cigarette cup 2, a magnetic induction coil 3, a button 6, an electric core 7, a PCB board 4, and the like. The upper part of the aerosol forming device such as figure 1 shown, others not shown.

[0060] Wherein, the cigarette cup 2 is used to accommodate the cigarette 1 . The bottom of the cigarette cup 2 has a cup hole for inserting the heating element 5 .

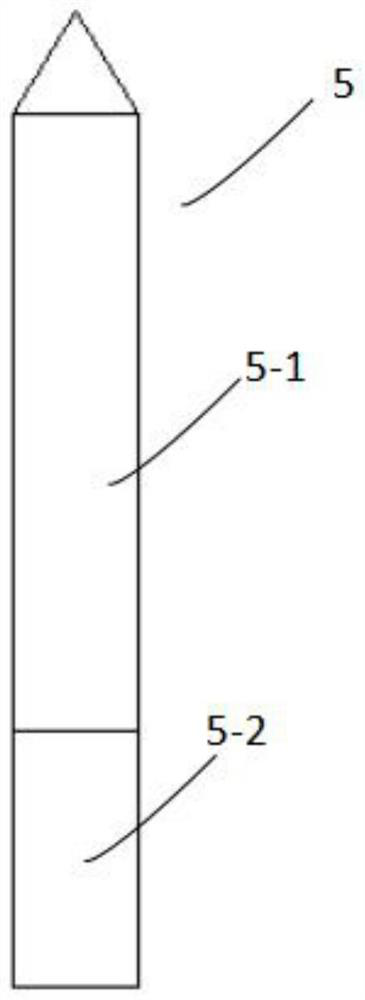

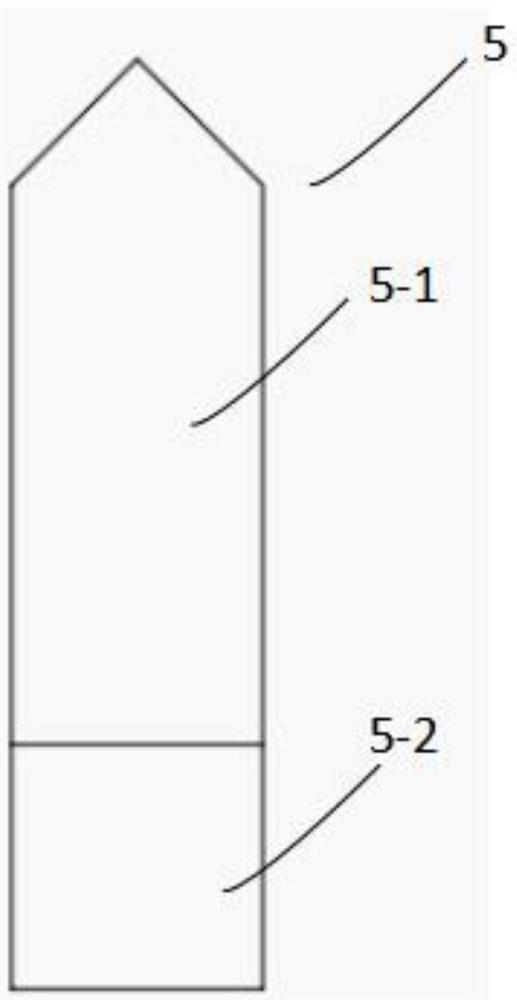

[0061] Such as figure 2 , the heating element 5 is a needle-shaped structure, and is used for centrally heating the cigarette 1 . The heating body 5 is composed of a heating body upper section 5-1 and a heating body lower section 5-2. At least the upper section 5 - 1 of the heating element and a part of the lower section 5 - 2 of the heating element are located in the tobacco cup 2 . The bottom of the heating element lower section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com