Wire aerodyne

A wire and roller mechanism technology, applied in the field of wire speeding, can solve the problems of cumbersome operation and danger, and achieve the effect of stable center of gravity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

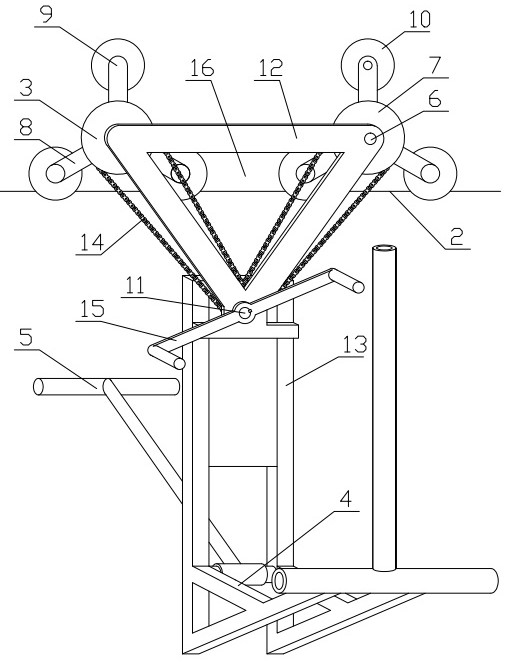

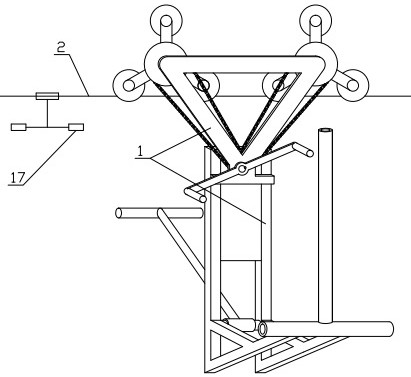

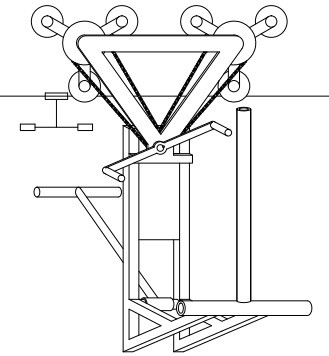

[0035] Such as Figure 1-7 As shown, the purpose of this embodiment is to provide a wire flying car, including at least two sets of roller mechanisms 3 connected to the top of the bracket 1. The bracket 1 includes an upper frame 12 and a lower frame 13. The upper frame 12 is an inverted triangle, and the two bottom corners are respectively connected. The roller mechanism 3, the top angle is connected to the conveyor belt 14 by driving the tower wheel, and the conveyor belt 14 is connected with the roller mechanism 3; The group of roller mechanisms 3 moves synchronously along the direction of the wire, so that the roller mechanism 3 swings along the direction of the wire with the axis of one group of rollers 10 as the center of a circle to achieve obstacle surmounting.

[0036] specific:

[0037] In this embodiment, the "front" guides the line flying car along the forward direction of the guide wire movement, and the "rear" guides the line flying car along the retreating direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com