Product manufacturing intelligent production scheduling system

A product manufacturing and production system technology, applied in the field of intelligent production scheduling systems for product manufacturing, can solve problems such as low work efficiency and chaotic production scheduling, and achieve the effect of avoiding production scheduling chaos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

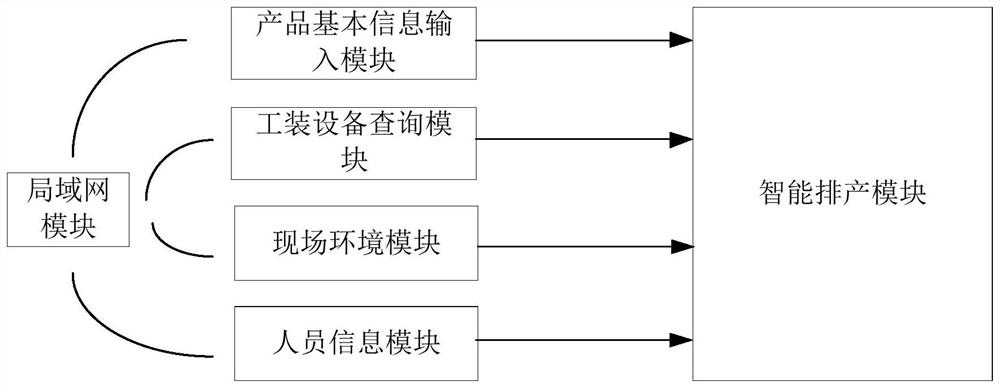

[0035] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a product manufacturing intelligent production scheduling system described in this embodiment, it includes:

[0036] The basic product information input module is used to input, query and modify the product name, station and operator information, station tooling equipment and station material information, and the entered information forms a database file;

[0037] The tooling equipment query module is used to query the type, quantity and status of the tooling equipment required for the product, and is used to query how many production lines the tooling equipment can meet;

[0038] The on-site environment module is used to enter the configuration information of the production line, and the entered information forms a database file;

[0039] The personnel information module is used to enter and query personnel information and personnel functions;

[0040] The intelligent produ...

specific Embodiment approach 2

[0053] Embodiment 2: This embodiment further explains Embodiment 1, and it also includes a permission module, which is used to set the user permissions of the system.

specific Embodiment approach 3

[0054] Specific implementation mode three: the following combination figure 1 Describe this embodiment, this embodiment will further explain the specific embodiment one, it also includes a local area network module, used to realize the basic product information input module, tooling equipment query module, on-site environment module, personnel information module and intelligent production scheduling module for data transfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com