Micro-channel heat exchanger virtual simulation experiment platform for measuring data

A micro-channel heat exchanger and virtual simulation technology, applied in the field of micro-channel heat exchanger virtual simulation experiment platform, can solve problems such as external force collision, display screen protection, heat exchanger damage, etc., to ensure stable lifting and stable support , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

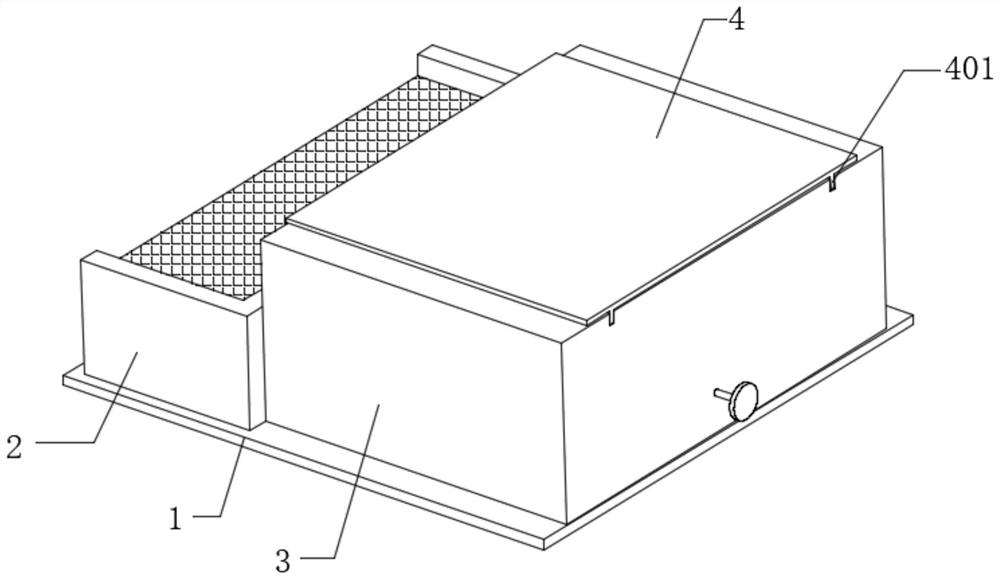

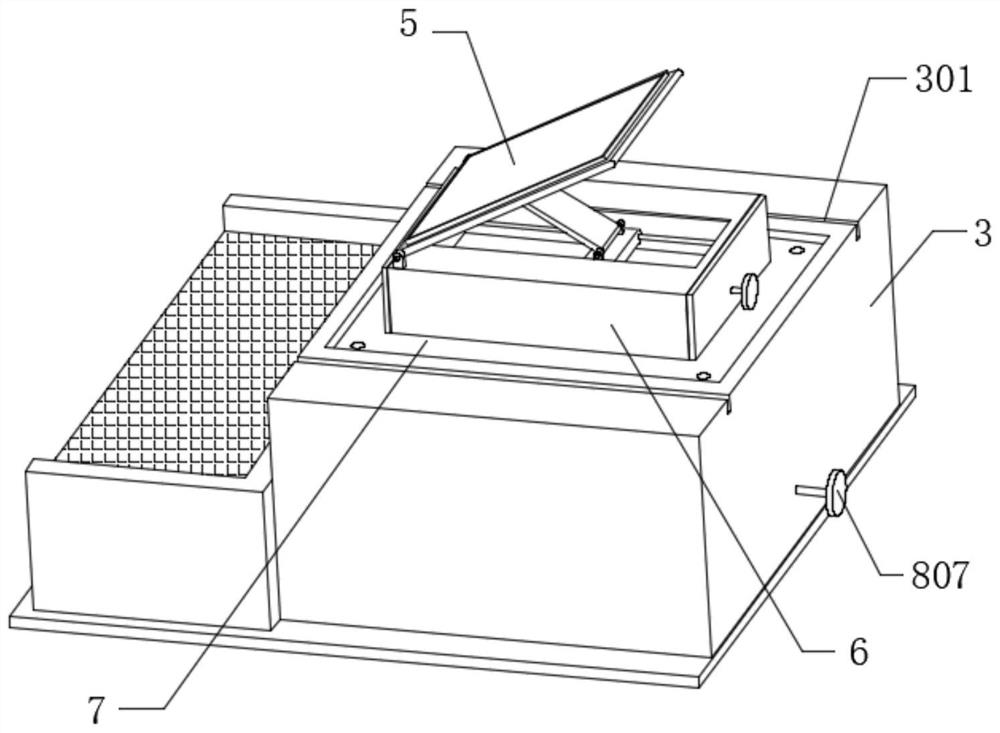

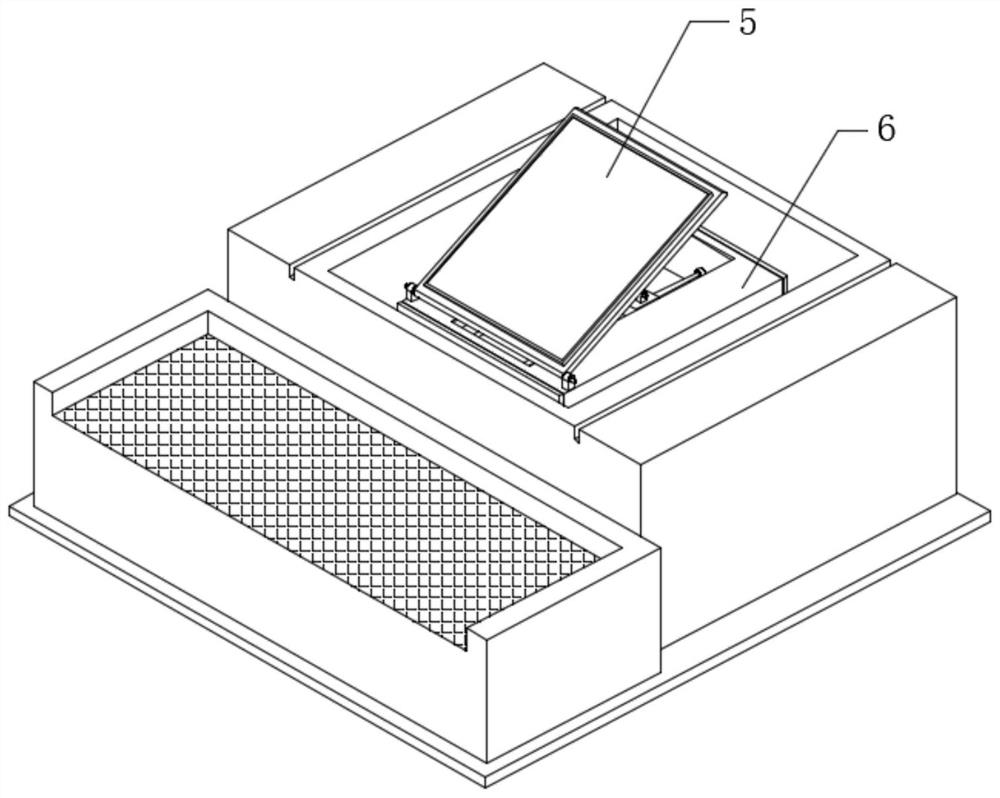

[0031] see Figure 1-7 As shown, a virtual simulation experiment platform for microchannel heat exchangers for measuring data, including the bottom of the device supporting the fixed plate 1, the main body of the display screen 5, the lifting control mechanism 8 and the turning mechanism 9, the bottom of the device supports the top of the fixed plate 1 The operation console 2 and the display screen protective box 3 are fixedly connected, and the top of the display screen protective box 3 is movably connected with the protective cover body 4. In the inner cavity of the box body 3;

[0032] The lifting control mechanism 8 includes a lifting load base plate 7, which is slidably connected to the inner cavity of the display screen protection box 3, and the bottom of the lift load base plate 7 is provided with a first fixed gear 8021, a second fixed gear 8022, and a worm body 8032 And lifting position control rack 804;

[0033] The overturning mechanism 9 includes a display screen...

Embodiment 2

[0048] see Figure 1-7 As shown, a virtual simulation experiment platform for microchannel heat exchangers for measuring data, including the bottom of the device supporting the fixed plate 1, the main body of the display screen 5, the lifting control mechanism 8 and the turning mechanism 9, the bottom of the device supports the top of the fixed plate 1 The operation console 2 and the display screen protective box 3 are fixedly connected, and the top of the display screen protective box 3 is movably connected with the protective cover body 4. In the inner cavity of the box body 3;

[0049] The lifting control mechanism 8 includes a lifting load base plate 7, which is slidably connected to the inner cavity of the display screen protection box 3, and the bottom of the lift load base plate 7 is provided with a first fixed gear 8021, a second fixed gear 8022, and a worm body 8032 And lifting position control rack 804;

[0050] The overturning mechanism 9 includes a display screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com