Skid-mounted hydrogen refueling station

A hydrogen refueling station, skid-mounted technology, applied in the field of hydrogen refueling equipment, can solve problems such as inconvenience, and achieve the effects of reducing costs, not easy to fall off naturally, and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

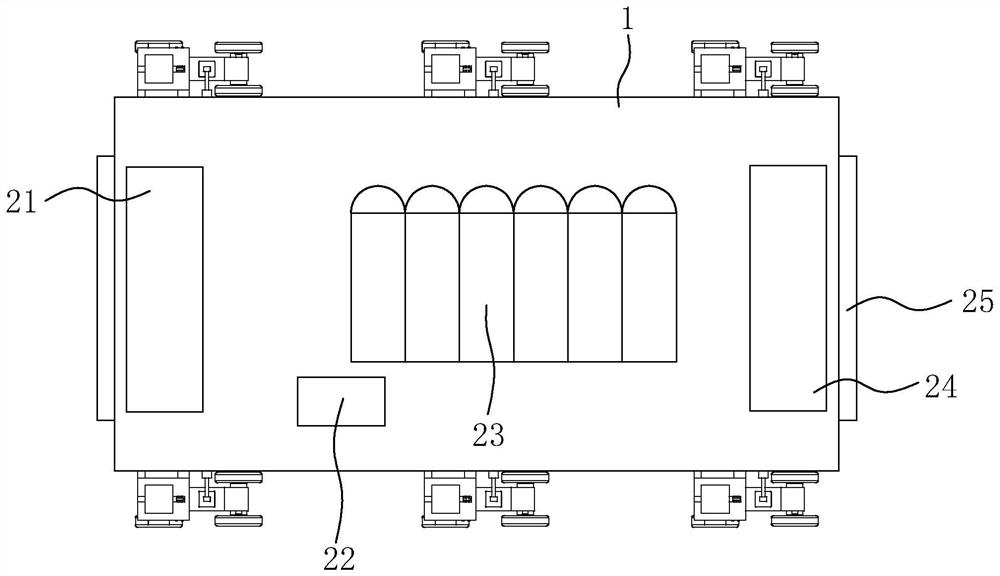

[0048] refer to figure 1, the skid-mounted hydrogen refueling station includes a chassis 1, an unloading column 21, a compressor 22, a hydrogen storage tank 23, and a filling machine 24. Both ends of the chassis 1 are equipped with electric rolling doors 25, an unloading column 21, and a compressor 22. , the hydrogen storage tank 23 and the filling machine 24 are all arranged in the cabinet 1, and the unloading column 21 and the filling machine 24 are respectively located at both ends of the cabinet 1, the unloading column 21, the compressor 22, the hydrogen storage tank 23 and the filling Machines 24 are connected in turn by pipelines.

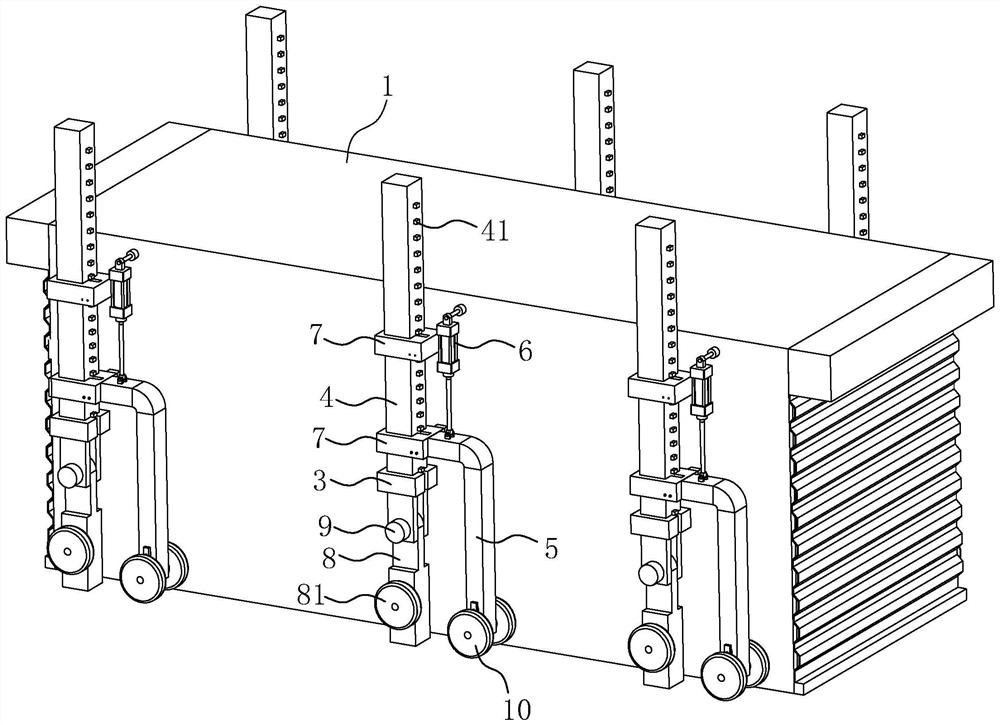

[0049] refer to figure 2 The skid-mounted hydrogen refueling station also includes at least three lifting systems installed outside the chassis 1. In this embodiment, there are six lifting systems, and the six lifting systems are evenly distributed on both sides of the chassis 1.

[0050] refer to figure 2 , the lifting system includes a...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is: refer to Figure 10 The limit pin 73 includes a pin rod 731, a button 732 fixedly connected to one end of the pin rod 731, a locking bar 733 arranged at the other end of the pin rod 731, and a second spring 734 sleeved on the pin rod 731. The pin rod 731 One end away from the button 732 is provided with a mounting groove, the locking bar 733 is arranged in the mounting groove and the middle part of the locking bar 733 is rotationally connected with the pin rod 731; the locking bar 733 can be accommodated in the mounting groove by rotation, or both ends Protrude out of the mounting slot.

[0067] The implementation principle of the second embodiment is: when it is necessary to install the limit pin 73 on the connecting seat 71, first rotate the locking bar 733, and store the locking bar 733 in the installation groove; then pass the pin bar 731 through the first The latch hole 75 or the second latch hole 76, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com