Subway tunnel anti-collapse structure and corresponding construction method thereof

A technology for tunnels and subways, used in earth-moving drilling, mining equipment, pillars/supports, etc., can solve problems such as labor-intensive, inconvenient use, inability to adjust the height of the support plate as needed, and achieve the effect of avoiding cumbersome and labor losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

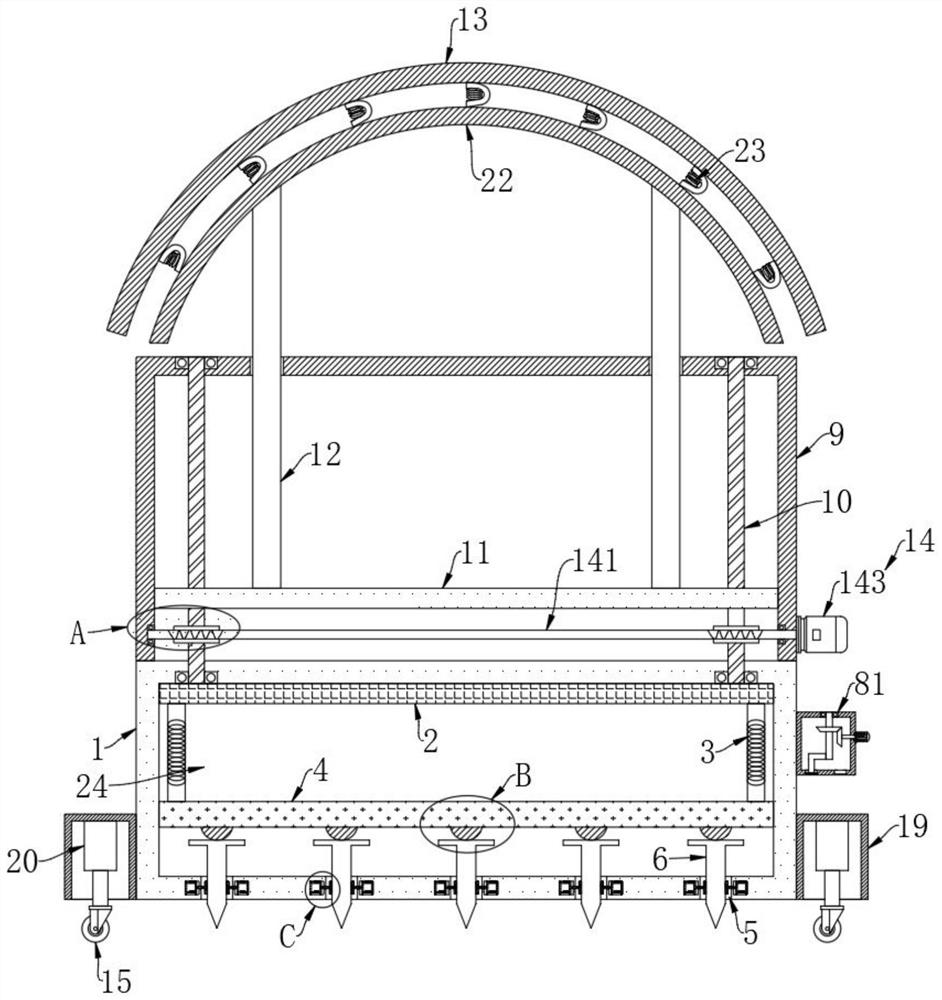

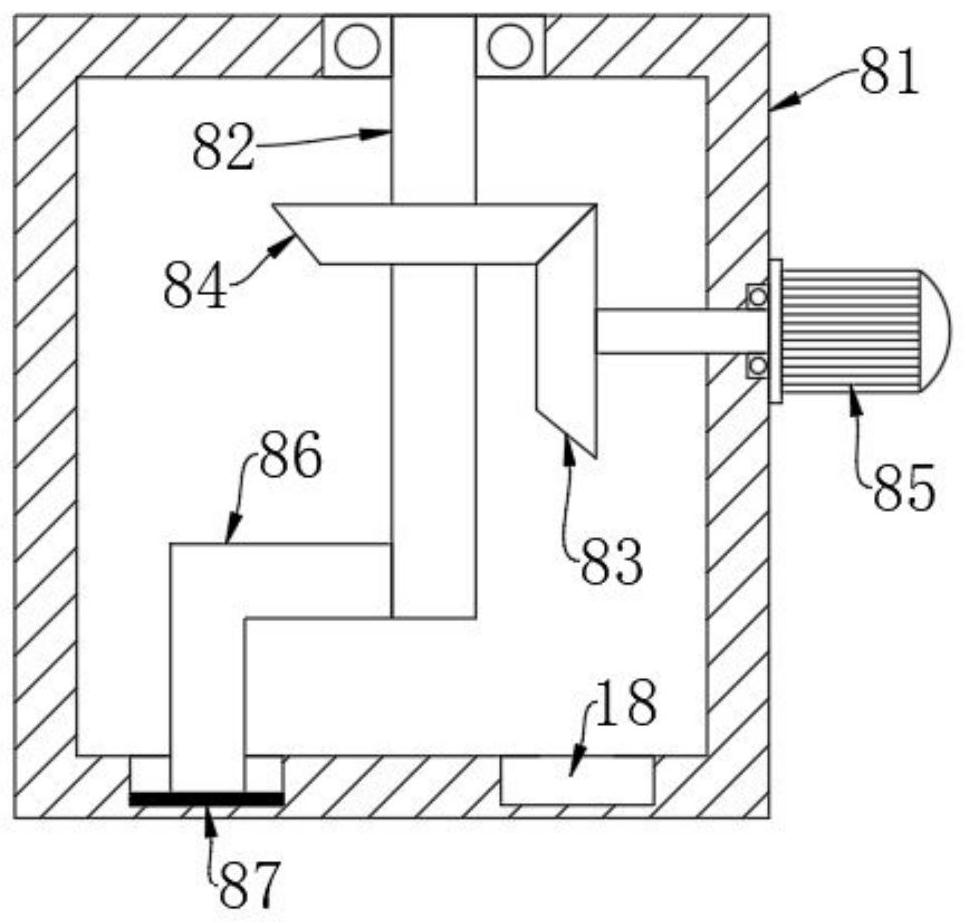

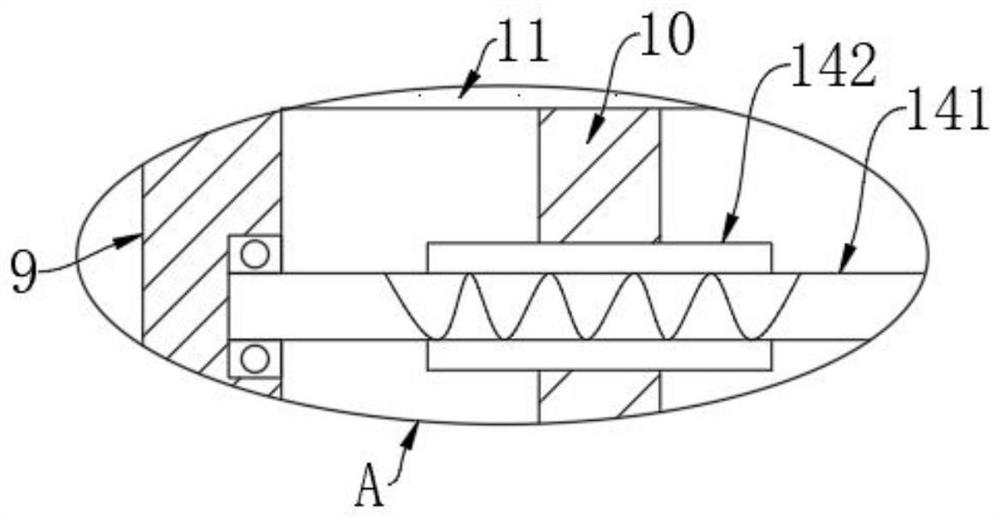

[0027] Such as Figure 1-5 As shown, a subway tunnel anti-collapse structure includes a base 1, a cavity 24 is opened on the base 1, and an electromagnetic plate 2 is embedded in the cavity 24, and the electromagnetic plate 2 is fixedly connected with a permanent magnet through a plurality of return springs 3 Pressing plate 4, and permanent magnet pressing plate 4 is slidably connected with cavity 24, and the lower end of base 1 is provided with a plurality of sliding cavities 5, and in sliding cavity 5, inserting rod 6 matched with permanent magnetic pressing plate 4 is slidably connected, and permanent magnetic pressing plate The lower end of 4 is fixedly connected with the projection 21 corresponding to the insertion rod 6, and the projection 21 is in contact with the top of the insertion rod 6. The setting of the projection 21 can reduce the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com