Low-conductivity cooling liquid and preparation method thereof

A low-conductivity, coolant technology, applied in the field of coolant, can solve problems such as equipment damage, equipment series electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of low-conductivity coolant, comprising the following steps:

[0034] A. Prepare deionized water, test its conductivity to ensure that it meets the requirements of first-grade water, mix qualified deionized water with ethylene glycol at 20-60°C, and stir for 10-30 minutes to form solution 1;

[0035] B: Mix the polyether, polytricarboxylic acid and dicarboxylic acid in the multi-effect composite preservative according to a certain ratio at 50-70°C, and stir for 30-60 minutes;

[0036] C: At 50-70°C, add multi-effect compound preservative and defoamer to solution 1 and stir for 30-60 minutes to form solution 3;

[0037] D: Filter solution 3 through a cation exchange resin to obtain the product.

Embodiment 1

[0039] Embodiment 1, a kind of low-conductivity cooling liquid, comprises the raw material of following parts by weight (this embodiment is in gram):

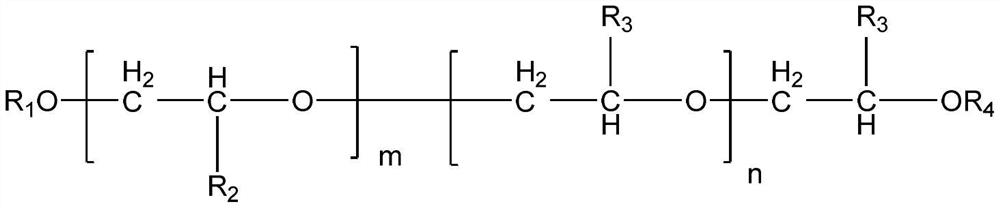

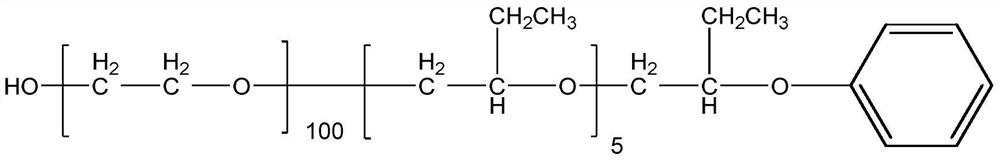

[0040] Deionized water 50, ethylene glycol 50, multi-effect compound preservative 0.02, defoamer (EX-504) 0.001; among them, the multi-effect compound preservative is polyether, polytricarboxylic acid, sebacic acid according to 1: 0.1:1 mixed; the polyether structure is:

[0041]

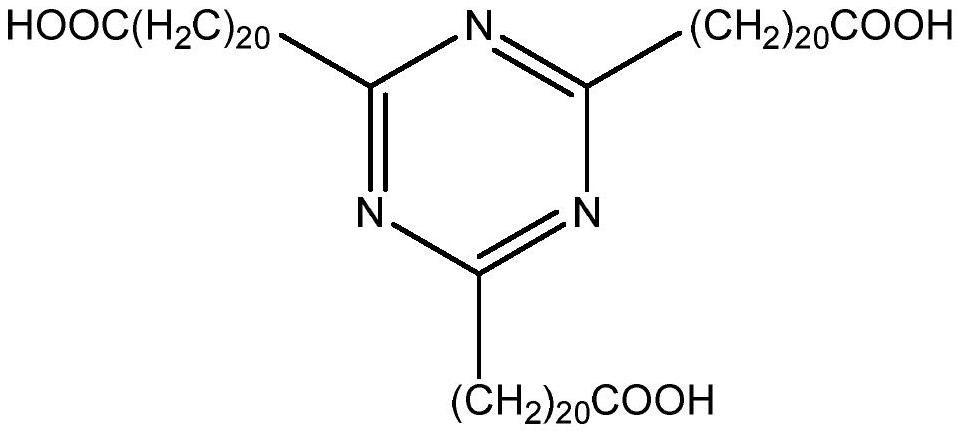

[0042] The polytricarboxylic acid structure is:

[0043]

[0044] A preparation method of low-conductivity coolant, comprising the following steps:

[0045] A: Prepare deionized water, test its conductivity to ensure that it meets the requirements of first-class water, mix 50 grams of deionized water and 50 grams of ethylene glycol at 25 ° C, and stir for 30 minutes to form solution 1;

[0046] B: At 50°C, mix 0.02 grams of multi-effect preservative, in which polyether, polytricarboxylic acid, and sebacic acid are mixed at a ratio of 1:0.1:1,...

Embodiment 2

[0053] Embodiment 2, a kind of low-conductivity coolant, comprises the raw material of following parts by weight (this embodiment is in gram):

[0054] Deionized water 10, ethylene glycol 10, multi-effect compound preservative 10, defoamer (CK-C155) 0.005; among them, the multi-effect compound preservative is polyether, polytricarboxylic acid, octadecanedioic acid Made by mixing 1:0.1:1;

[0055] The polyether structure is:

[0056]

[0057] The polytricarboxylic acid structure is:

[0058]

[0059] A preparation method of low-conductivity coolant, comprising the following steps:

[0060] A: Prepare deionized water, test its conductivity to ensure that it meets the requirements of first-class water, mix 10 grams of deionized water with 90 grams of ethylene glycol at 60 ° C, and stir for 10 minutes to form solution 1;

[0061] B: At 70°C, mix 10 grams of multi-effect preservative, in which polyether, polytricarboxylic acid, and octadecanedioic acid are mixed in a ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com