Long-distance transportation device for carrier plate glass and packaging method for reducing damage of long-distance transportation device

A long-distance transportation and glass technology, which is applied in the direction of transportation and packaging, packaging of vulnerable items, packaging, etc., can solve the problems of the bottom of the carrier glass being damaged by collision, high glass breakage rate, and poor quality, and achieve a low breakage rate , high yield and output, and the effect of being put into use safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

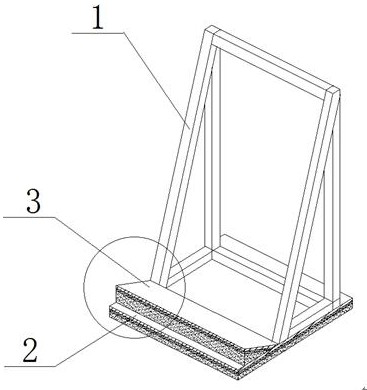

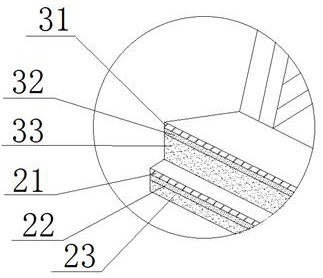

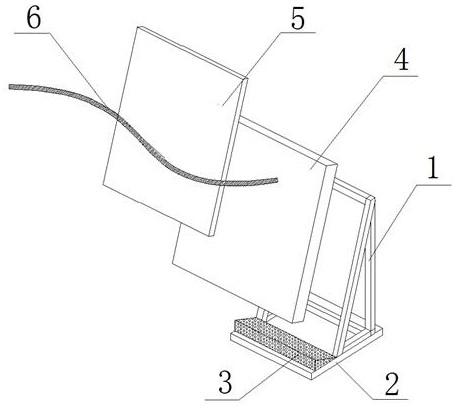

[0040] Such as figure 1 As shown, the long-distance transportation device for carrier glass according to the present invention includes a support frame 1 with an inclined side. 3, of which:

[0041] The support frame 1 has a right-angled triangle in cross-section, and includes a vertical rod vertically arranged to the bottom plate 2, a flat rod vertically arranged to the vertical rod, and a diagonal rod connected to the vertical rod and the flat rod. 4 The inclined surface in contact with the back; the inclination angle of the inclined bar is the angle at which the carrier glass 4 is placed;

[0042] The side baffle 3 has a right-angled triangle in cross section and includes a limiting surface perpendicular to the inclined surface of the support frame 1, and the limiting surface is in contact with the bottom of the carrier glass 4;

[0043] Base plate 2, which is fixed with support frame 1 and side baffle plate 3;

[0044] Wherein: the width of the support frame 1 and the s...

Embodiment 2

[0054] Preferably, the side baffle 3 and the bottom plate 2 are integrally processed, and the support frame 1 is placed on the side of the bottom plate 2 away from the side baffle 3 .

[0055] In this embodiment, in order to improve the fixing strength of the side baffle 3 and provide sufficient support for the carrier glass 4, the side baffle 3 and the bottom plate 2 are combined into one, and only the position of the support frame 1 needs to be adjusted appropriately The assembly of the transport device can be completed.

Embodiment 3

[0057] Preferably, the upper surface of the bottom plate 2 is convexly provided with a limit block that blocks the sliding of the support frame 1 .

[0058] In the above-mentioned embodiment, since the side baffle 3 and the bottom plate 2 are integrally processed, and in order to prevent the metal support frame 1 from sliding down from the bottom plate 2, it is necessary to add limit blocks around the bottom of the support frame 1; when the support frame 1 is subjected to an external force First, the position is limited by the limit block and the external force is transmitted to the bottom plate 2, and the buffer material of the bottom plate 2 is used to absorb energy, and the external force is converted into heat energy, thereby reducing damage to the carrier glass 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com