Oven and control method thereof

A control method and baking technology, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problems of irrespective of baking time, inedible food, and inability to accurately define, so as not to pollute food, install Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

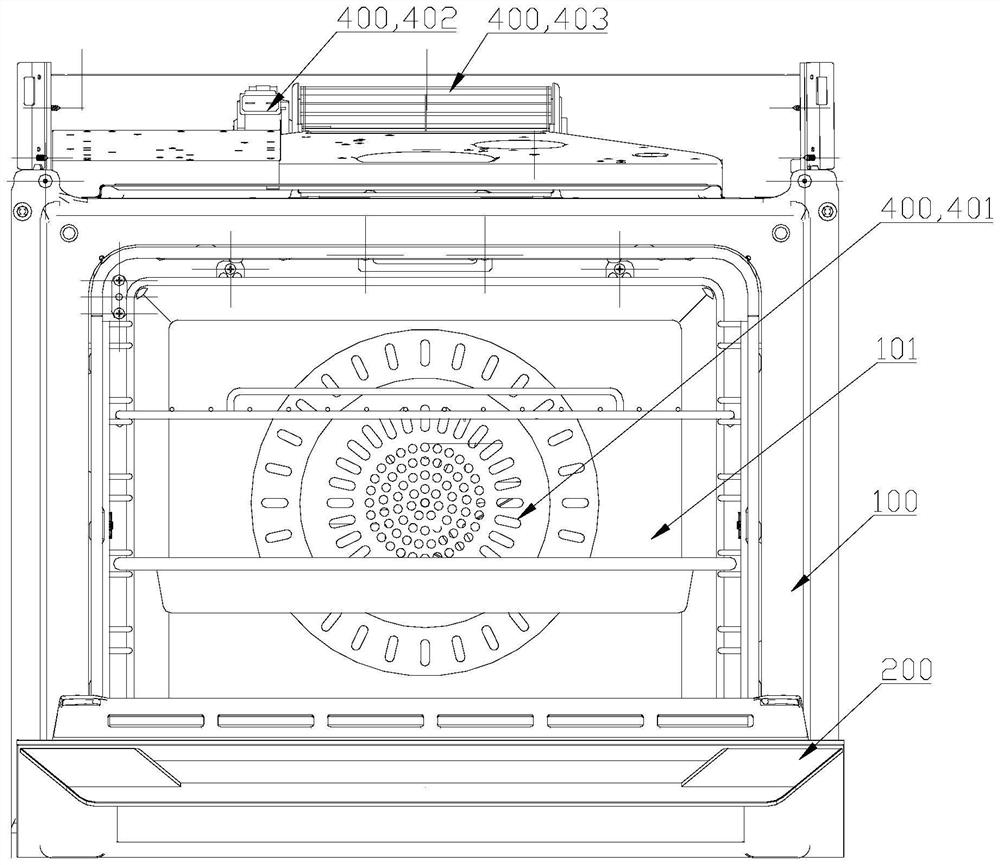

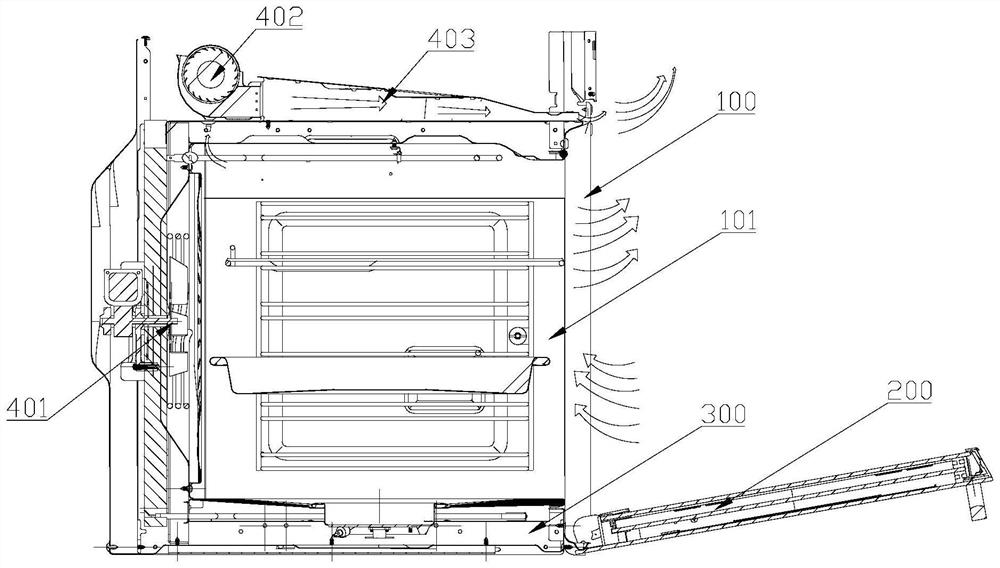

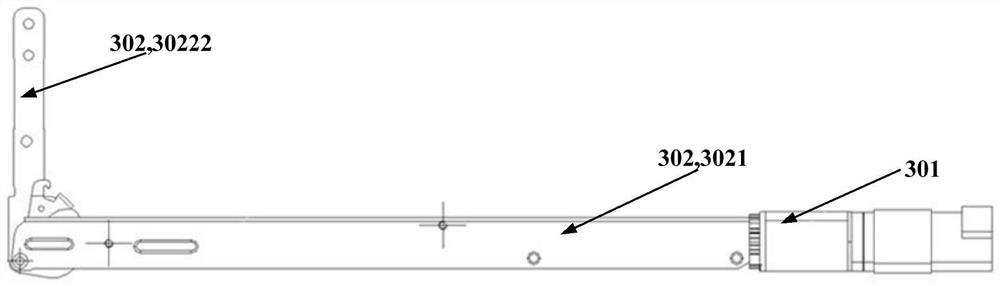

[0052] like Figure 1 to Figure 3 As shown, an oven is provided in the embodiment of the present invention, comprising: a box body 100, which has a baking chamber 101 inside, and the front end of the baking chamber 101 has an opening; a door body 200, which can pivot ground on the box body 100; the automatic door opening mechanism 300 is used to drive the door body 200 to open or close the opening of the baking chamber 101; the heat dissipation mechanism 400 is set in the box body 100, and the heat dissipation The mechanism 400 is at least used to exhaust the gas in the baking chamber 101 to the outside, so as to reduce the temperature in the baking chamber 101 .

[0053]In this embodiment, the automatic door opening and closing mechanism 300 is controlled to drive the door body 200 to open to quickly discharge the hot air in the baking chamber 101 to realize rapid cooling of the baking chamber 101. The automatic door opening and closing mechanism 300 cooperates with the heat ...

Embodiment 2

[0073] like Figure 4 and Figure 5 As shown, an oven control method is also provided in an embodiment of the present invention, which is applied to any of the ovens described above, including the following steps:

[0074] Step S1: After the baking is finished, if the temperature in the baking chamber 101 is greater than the first preset temperature, control the automatic door opening mechanism 300 to drive the door body 200 to open the opening of the baking chamber 101;

[0075] Step S2: activate the heat dissipation mechanism 400 to discharge the hot air in the baking chamber 101 to the outside;

[0076] Step S3: until the temperature in the baking chamber 101 is less than or equal to the second preset temperature, control the automatic door opening mechanism 300 to drive the door body 200 to close the opening of the baking chamber 101, wherein the first preset temperature is greater than the second preset temperature temperature;

[0077] Step S4: Control the cooling mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com