Cylinder impact test device and test method

A technology of impact test and test method, applied in impact test, measurement device, test of machine/structural components, etc., can solve problems such as high cost and long test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

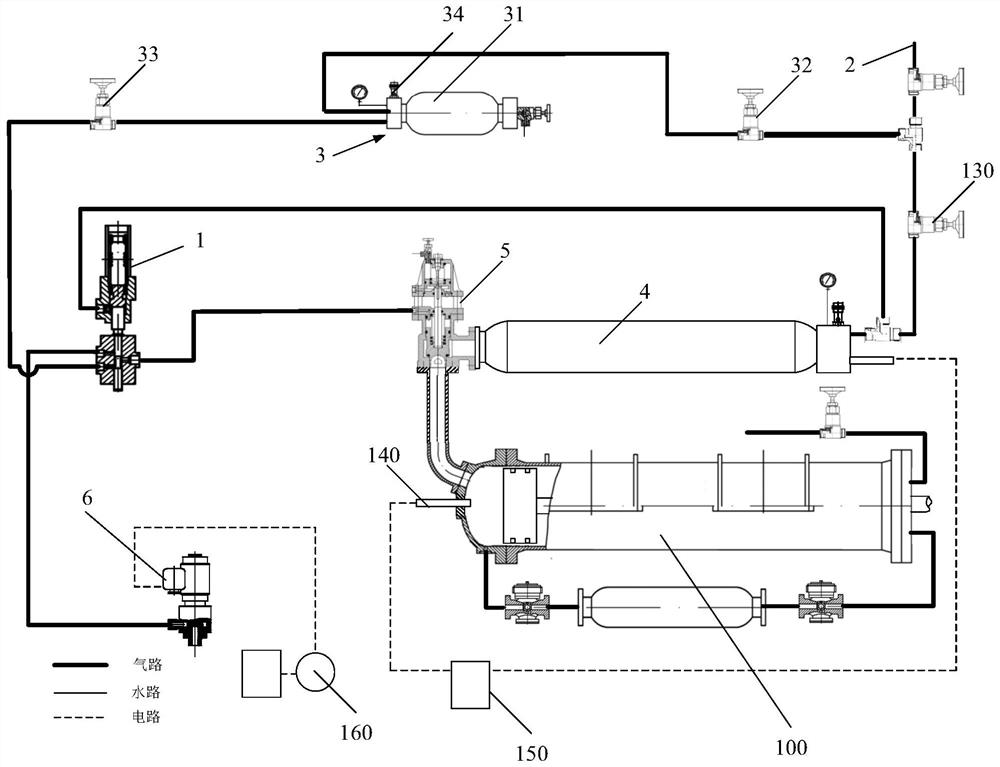

[0036] For ease of understanding, here are figure 1 Be explained, figure 1 It is a structural schematic diagram of the cylinder impact test device provided by the embodiment of the present disclosure, refer tofigure 1 It can be seen that the embodiment of the present disclosure provides a cylinder impact test device. The cylinder impact test device includes: the cylinder impact test device includes an automatic cut-off component 1, an air source 2, a closing pressure supply component 3, an impact gas cylinder 4, a start valve 5 and Test switching valve 6.

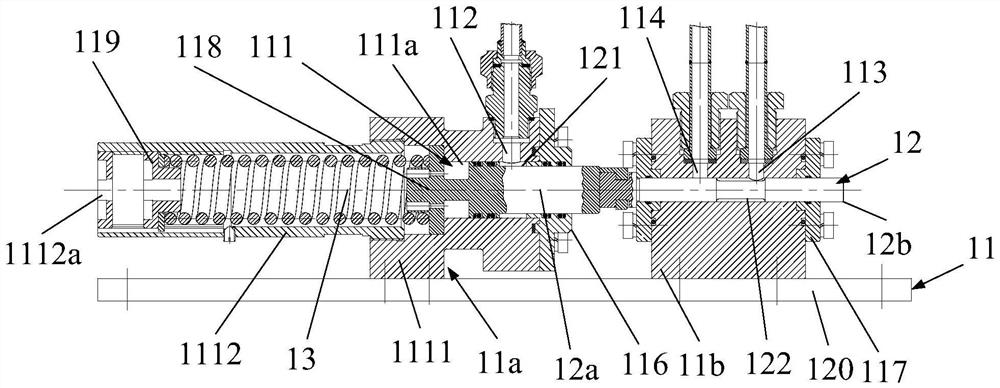

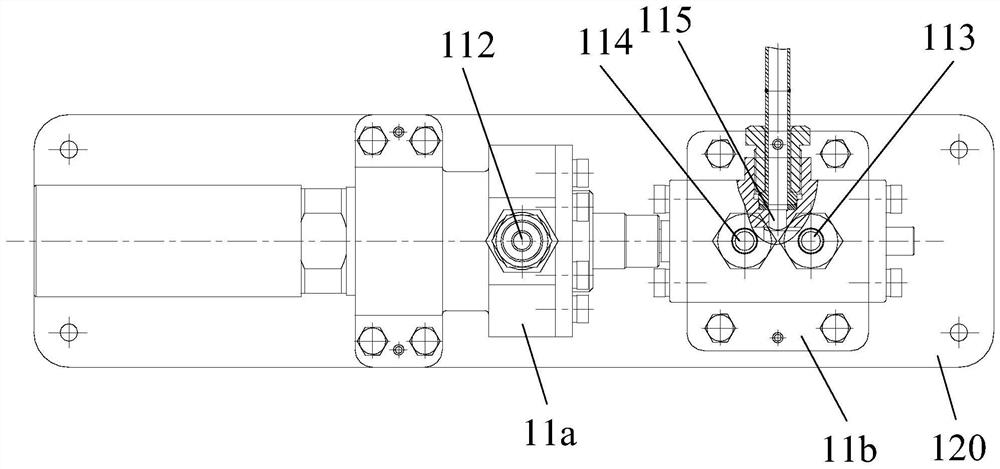

[0037] figure 2 is a schematic structural diagram of the automatic cut-off component provided by the embodiment of the present disclosure, image 3 is a top view of the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com