Packing device for comprehensively winding heavy object

A heavy and comprehensive technology, which is applied in the direction of packaging, transportation and packaging, and item rotation wrapping, etc., can solve the problems of reducing packaging efficiency, inability to package workpieces, and increasing labor costs, so as to save quantity, reduce physical consumption, and reduce manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

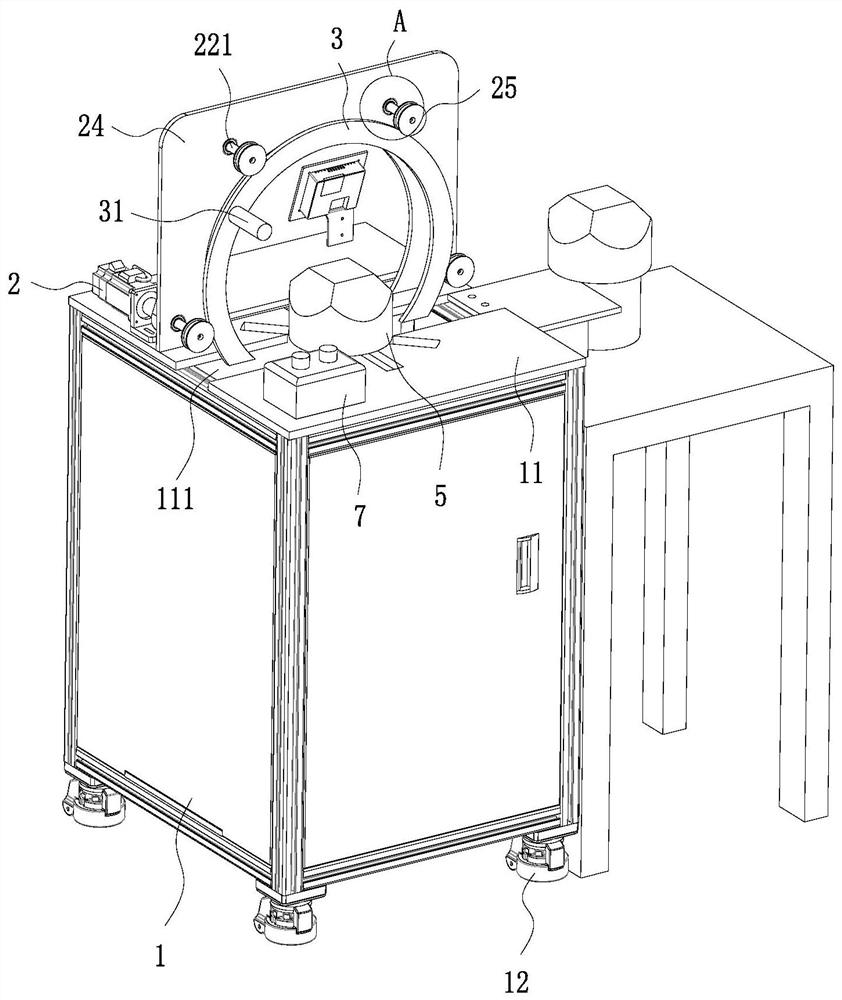

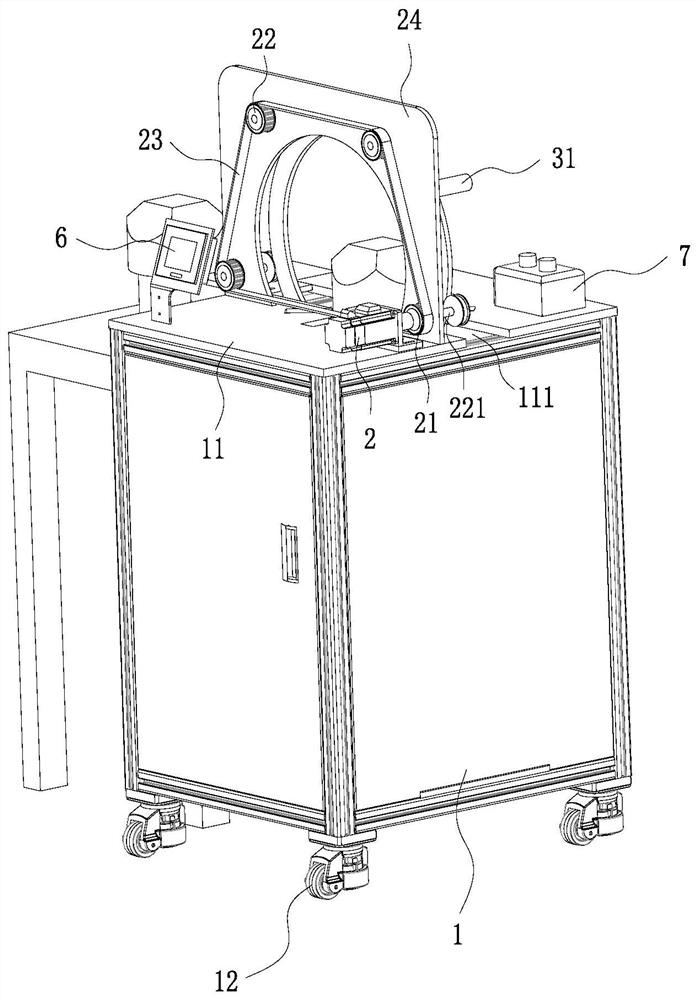

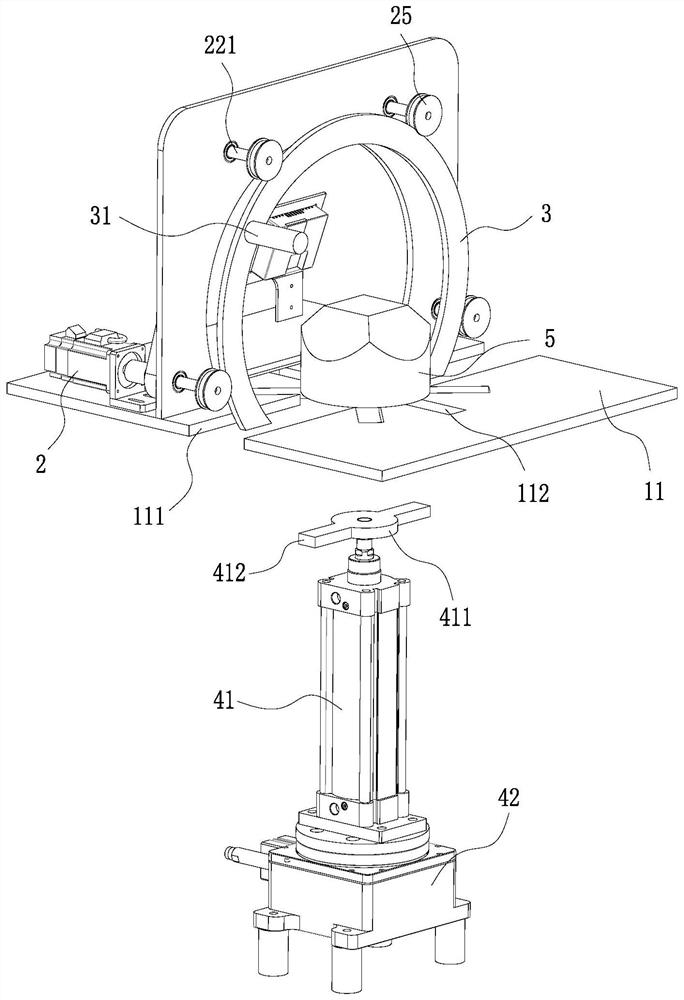

[0034] Such as Figure 1 to 5 As shown, the present embodiment shows a packaging apparatus for full wrapping weight, including a winding mechanism, a rotating mechanism, and a fixing seat 1, and the fixing seat 1 is provided with a placement plate 11 for placing the workpiece 5, the The retaining plate 24 is mounted vertically, the winding mechanism including a drive assembly and a winding assembly including a drive motor 2, a active wheel 21, a plurality of driven wheels 22 and a drive wheel 21 and a driven wheel. The belt 23 of 22, the winding assembly includes a rotating ring 3 and a winding rod 31, the drive motor 2 and the rotating ring 3, respectively, on both sides of the fixing plate 24, and the drive wheel 21 is mounted in the drive motor 2. The output end, the fixing plate 24 is provided with a plurality of runner 25, the driven wheel 22 on one side of the retaining plate 24, the driven wheel 22 and the drive wheel 21 through belt 23 Realizing the transmission, the drive ...

Embodiment 2

[0041] Such as Figure 6 to 8 As shown, the main difference between the present embodiment and the first embodiment is that the rotating mechanism includes two top-out cylinders 43, and the output end of the two top-out cylinders 43 is provided with a rod 431, the two top out The cylinder 43 is mounted on the placement plate 11, the two top-out cylinders 43 are respectively located on both sides of the avoidance groove 111, and the two top-out cylinders 43 are centrally symmetrical in the center of the workpiece 5. When the workpiece 5 is rotated, the two top-out cylinder 43 simultaneously activates the top rod 431 on the side of the workpiece 5, and the workpiece 5 is rotated under the action of the two sides 431, the winding assembly The workpiece 5 can be re-wound again until the entire workpiece 5 is completely wrapped, the city embodiment does not require manual moving workpieces 5, which can save the number of staff, and can reduce the consumption of staff. However, thereby r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com