Fermented milk beverage and preparation method thereof

A technology for fermented milk beverages and fermented milk, which is applied to bacteria and lactobacilli used in dairy products and food preparations, can solve the problems of inability to kill the taste, affect the taste of beverages, and the fermented flavor is not prominent, and achieves an improved overall flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

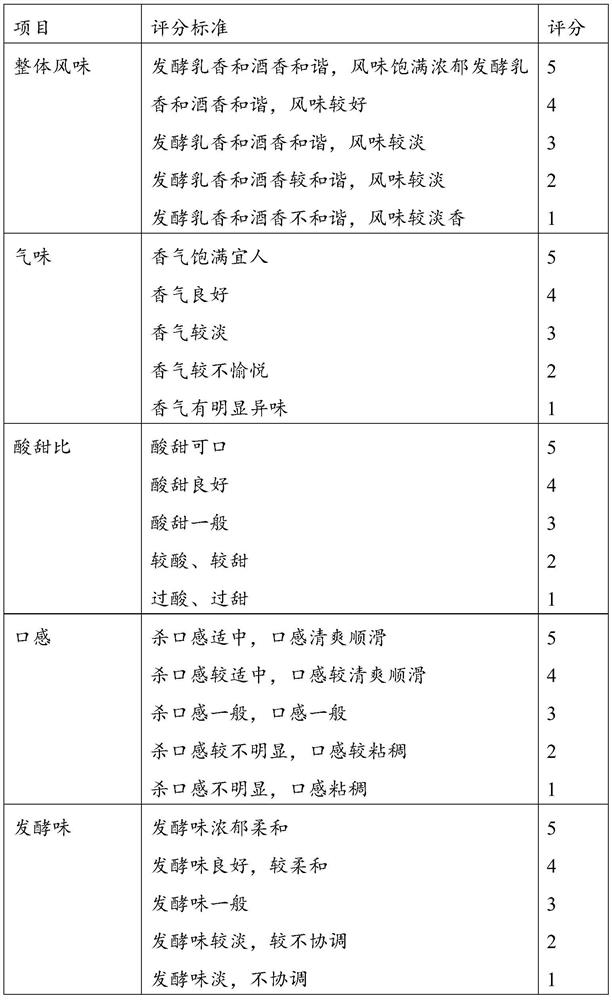

Examples

Embodiment 1

[0027] Preheat 100 parts of raw milk to 60-65°C, homogenize under 18-20Mpa pressure, 90°C, sterilize for 300s, then cool down to 25-30°C, add 0.005-0.008 parts of lactic acid bacteria to ferment for 15-17 hours to obtain fermented milk Milk, cooled to below 10°C for later use; after mixing 15 parts of concentrated pineapple juice, 7 parts of crystalline fructose, 0.25 parts of soybean polysaccharide, 0.25 parts of pectin, 0.06 parts of anhydrous citric acid, and 77 parts of water, the Stir for 15-20 minutes to prepare the prepared liquid, then lower the temperature to 15-30°C for later use; mix 25 parts of fermented milk and 75 parts of the prepared liquid evenly at 10-30°C, adjust the acid to pH 3.75-3.8 after constant volume, Raise the temperature to 55-75°C, homogenize at 15-25Mpa until the mixture is uniform, then sterilize at 90°C for 300s, then cool down to 25-30°C, add 0.008 parts of Kluyveromyces marx (Kr. Ruver's yeast (Danisco) 0.005 portion fermented for 48h. Final...

Embodiment 2

[0029] Preheat 90 parts of raw milk and 10 parts of honey to 60-65°C, homogenize under 18-20Mpa pressure, sterilize at 90°C for 300s, then cool down to 37°C, add 0.005-0.008 parts of lactic acid bacteria to ferment for 10-12 hours To obtain fermented milk, cool it below 10°C for use; mix 15 parts of concentrated grapefruit juice, 0.05 parts of carboxymethyl cellulose (CMC), 0.15 parts of soybean polysaccharide, 0.35 parts of pectin, 0.06 parts of anhydrous citric acid, and 85 parts of water After mixing, stir at 60-75°C for 15-20 minutes to prepare the preparation liquid, then cool down to 15-30°C for later use; mix 20 parts of fermented milk and 80 parts of preparation liquid at 10-30°C, Adjust acid to pH 3.8-3.9, heat up to 55-75°C, homogenize at 15-25Mpa until the mixture is uniform, then sterilize at 90°C for 300s, then cool down to 25-30°C, insert Kluyveromyces marxe ( Hansen) 0.008 parts, Saccharomyces cerevisiae (Le Sifu) 0.03 parts fermented for 24h. Finally, the ferm...

Embodiment 3

[0031] Preheat 100 parts of reconstituted milk to 60-65°C, homogenize under 18-20Mpa pressure, sterilize at 90°C for 300s, then cool down to 25-28°C, add 0.005-0.008 parts of lactic acid bacteria and ferment for 15-17 hours to obtain fermented milk Milk, cooled to below 10°C for later use; mix 10 parts of concentrated grape juice, 7 parts of high fructose syrup, 0.15 parts of soybean polysaccharide, 0.35 parts of pectin, 0.06 parts of anhydrous citric acid, 0.02 parts of lactic acid, and 83 parts of water. Stir at 60-75°C for 15-20 minutes to prepare the blended solution, then cool down to 15-30°C for later use; mix 10 parts of fermented milk and 90 parts of the blended liquid at 10-30°C, adjust the acidity to pH after constant volume 3.6~3.65, heat up to 55~75°C, homogenize at 15~25Mpa until the mixture is homogeneous, then sterilize at 90°C for 300s, then cool down to 25~30°C, insert Kluyveromyces marx (Kr. Hansen) 0.008 parts, 0.03 parts of Saccharomyces cerevisiae (Le Sifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com