Prediction method for full characteristic curve of centrifugal pump

A full-characteristic curve, centrifugal pump technology, applied in pump control, non-variable-capacity pumps, special data processing applications, etc., can solve the problems of simulation errors in the hydraulic transient process of pumping stations, inability to effectively guide engineering design, etc. Engineering design process, saving manpower and material resources, strong theoretical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

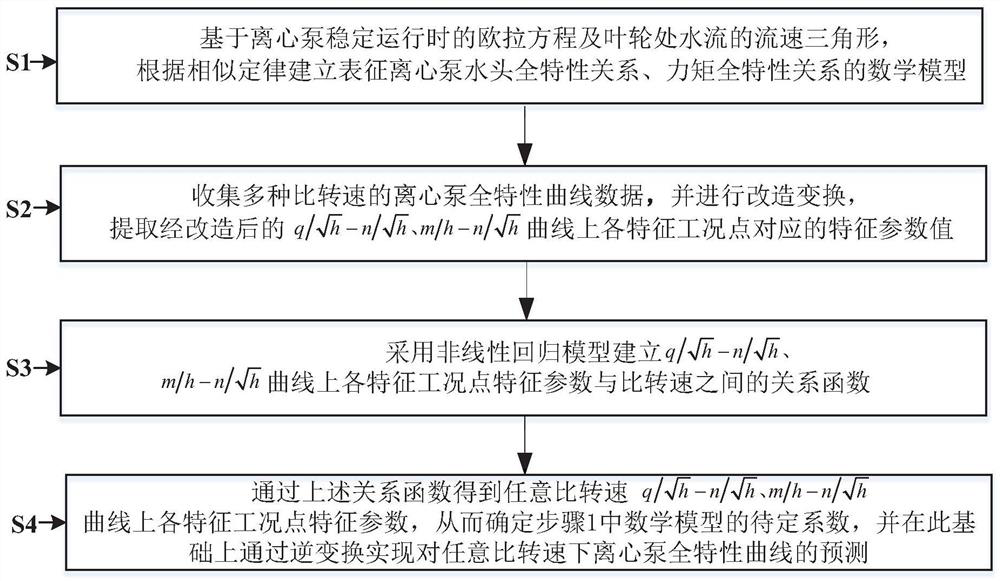

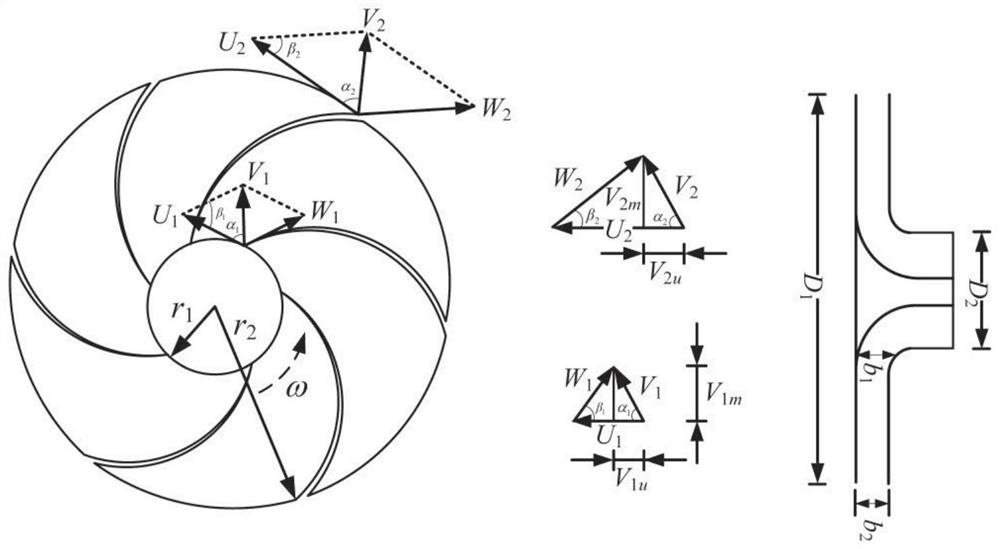

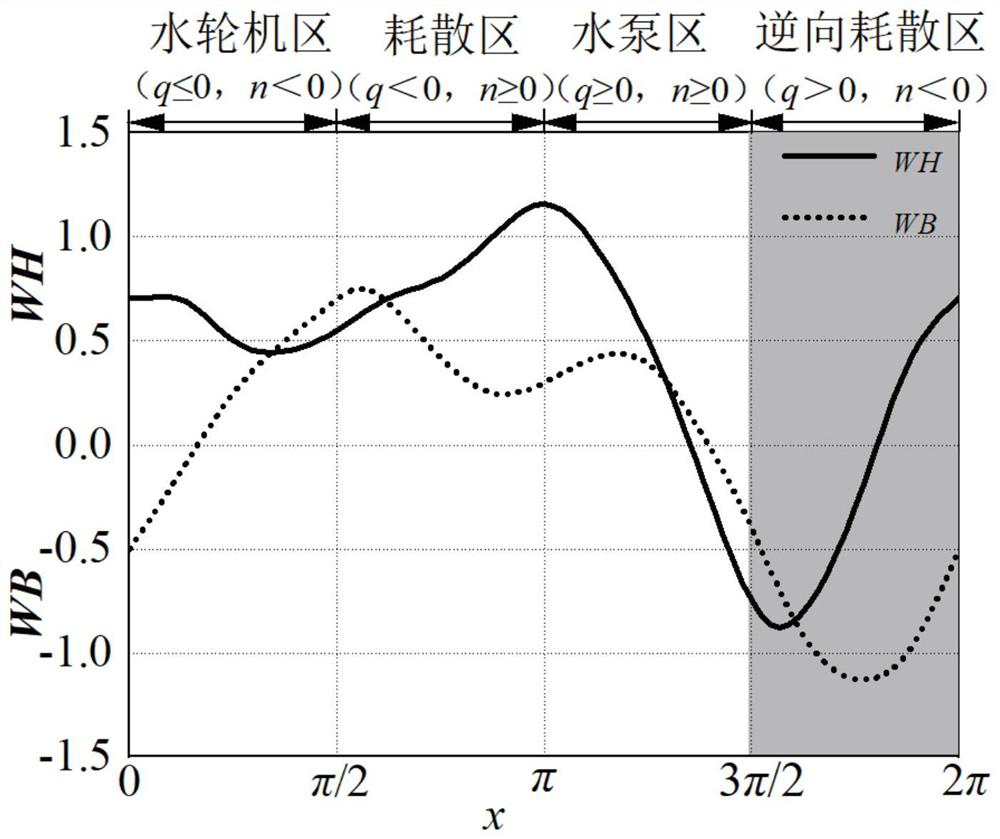

[0056] For the existing numerical simulation of the hydraulic transient process of the pumping station, the method of simply applying the full characteristic curve of the centrifugal pump with adjacent specific speeds due to the lack of the full characteristic curve of the measured centrifugal pump will bring large errors to the calculation results, which will affect the preliminary design of the pumping station. bring a lot of inconvenience. The present invention proposes a prediction method for the full characteristic curve of a centrifugal pump, based on the Euler equation and the flow velocity triangle of the water flow at the impeller when the centrifugal pump is in stable operation, and according to the law of similarity, a method representing the full characteristic relationship of the water head and the full characteristic relationship of the torque of the centrifugal pump is established. Mathematical model; collect the data of the full characteristic curve of the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com