Fabricated building prefabricated slab capable of rapidly installing pipelines

A prefabricated, prefabricated panel technology, applied in construction, building components, building structures, etc., can solve the problems of inconvenient installation and operation, unfavorable development of building prefabricated panels, and unfavorable prefabricated panel industry development, and achieve the effect of easy installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

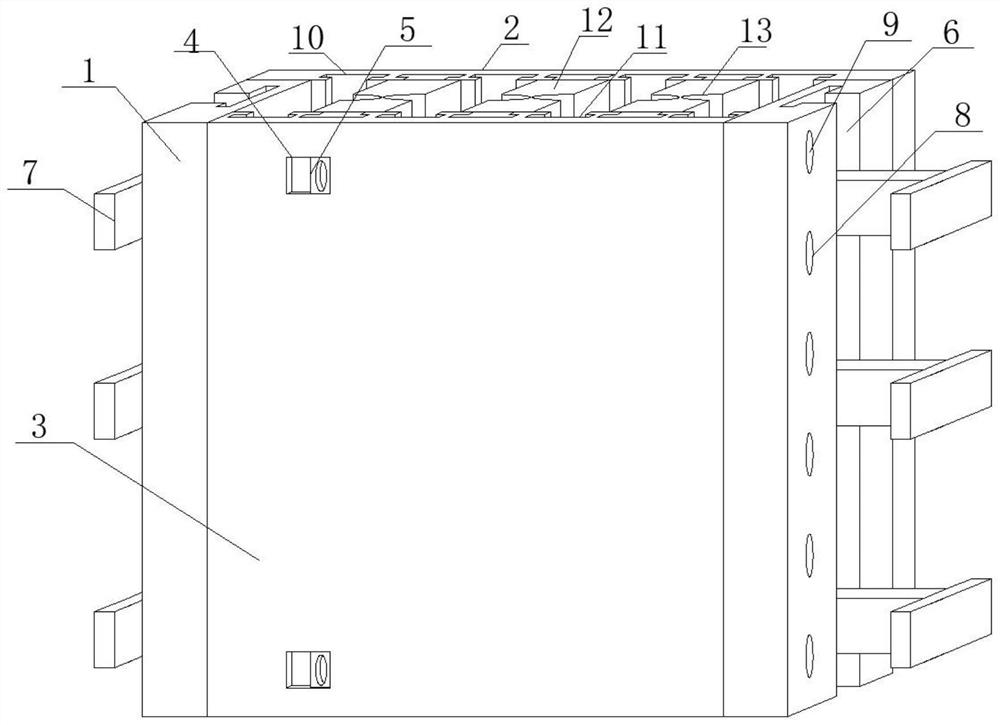

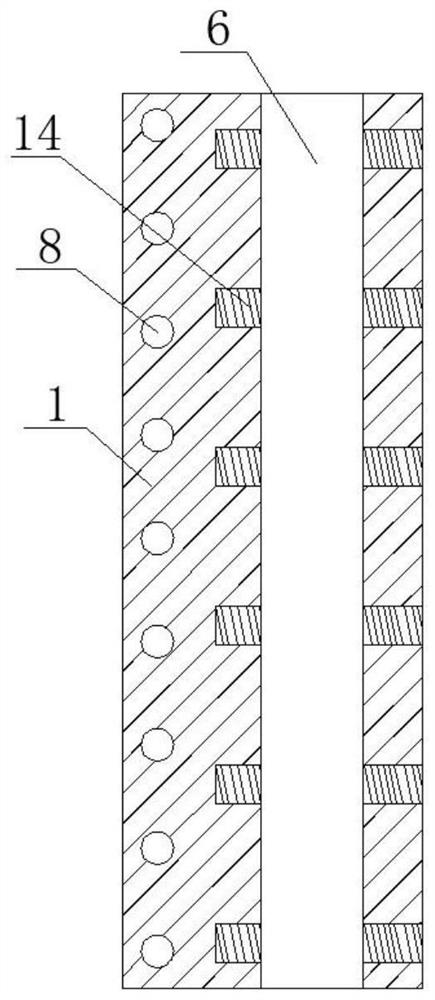

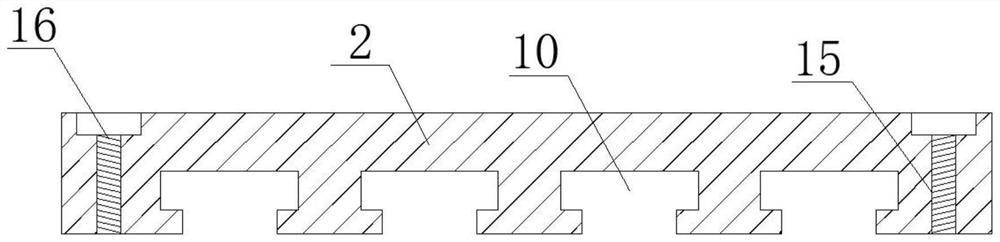

[0028] see Figure 1-2 , in an embodiment of the present invention, a prefabricated prefabricated building panel capable of quickly installing pipes, including a supporting side panel 1, one side of the supporting side panel 1 is butted with a fixed back panel 2, and the sides of the supporting side panels 1 are butted There is a sealed front plate 3, and the number of supporting side plates 1 is multiple, and the multiple supporting side plates 1 are arranged symmetrically in parallel in groups of two, and the sides of a group of supporting side plates 1 are vertically docked and arranged on the fixed back plate 2. One side is close to the edge position, the sealing front plate 3 and the fixed rear plate 2 are arranged parallel to each other, and the two sides of the sealing front plate 3 are vertically docked and arranged between a group of supporting side plates 1, and the side is far away from the fixed rear plate 2 One side of the sealing front plate 3 is symmetrically pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com