Screw dismounting mechanism and dismounting device

A screw and rack technology, applied in the field of screw removal mechanism and disassembly device, can solve the problem of heavy load of the lifting mechanism and achieve the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

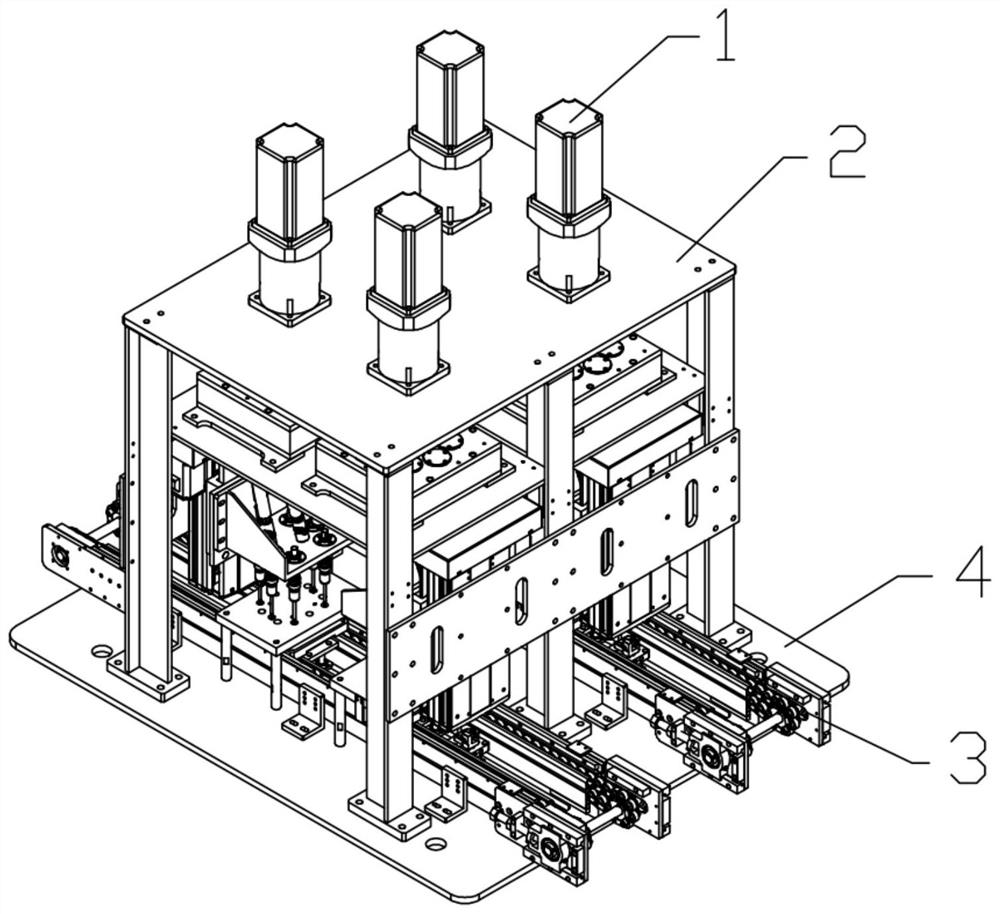

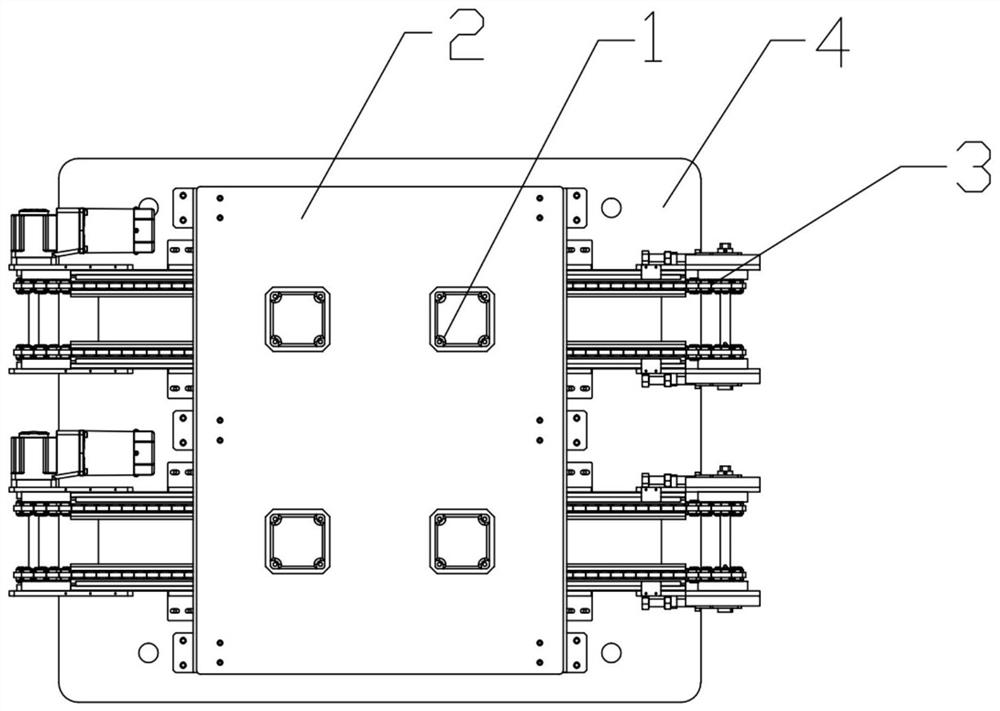

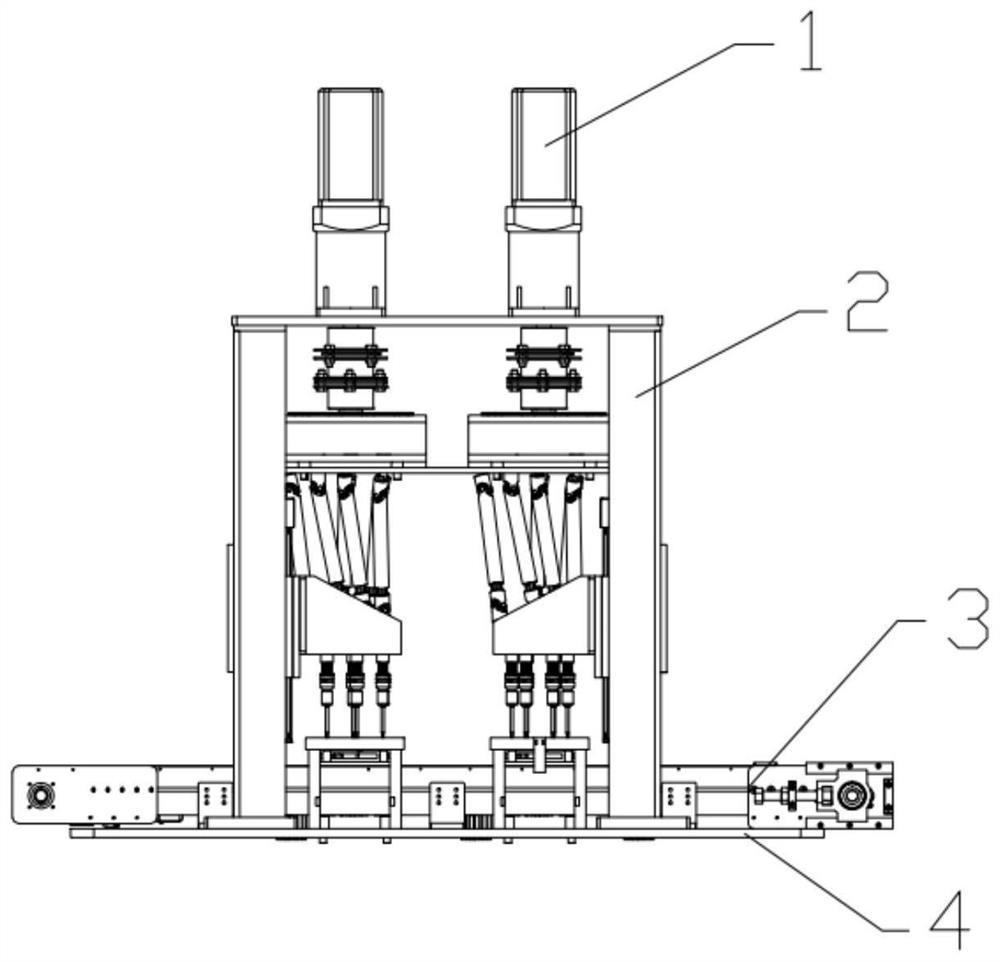

[0033] Please refer to Figure 1 to Figure 11 , the embodiment of the present invention provides a screw removal mechanism, including: a frame 2 and a screw removal assembly 1 arranged on the frame 2;

[0034] The screw removal assembly 1 includes a linear slide module 17, a support 15, a drive motor 11, a multi-axis output gearbox 13, a plurality of universal telescopic couplings 14 and a plurality of floating screwdrivers 16; the upper end of the frame 2 is arranged up and down There are a first mounting plate 21 and a second mounting plate 22; one side of the frame 2 is provided with a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com