Composite molding method for carbon fiber sports shoe sole

A composite molding, carbon fiber technology, applied in the direction of shoemaking machinery, footwear, footwear, etc., can solve the problems of foot nail bending, uneven force at the foot nail connection, fracture, etc., to avoid easy bending, The effect of improving strength and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

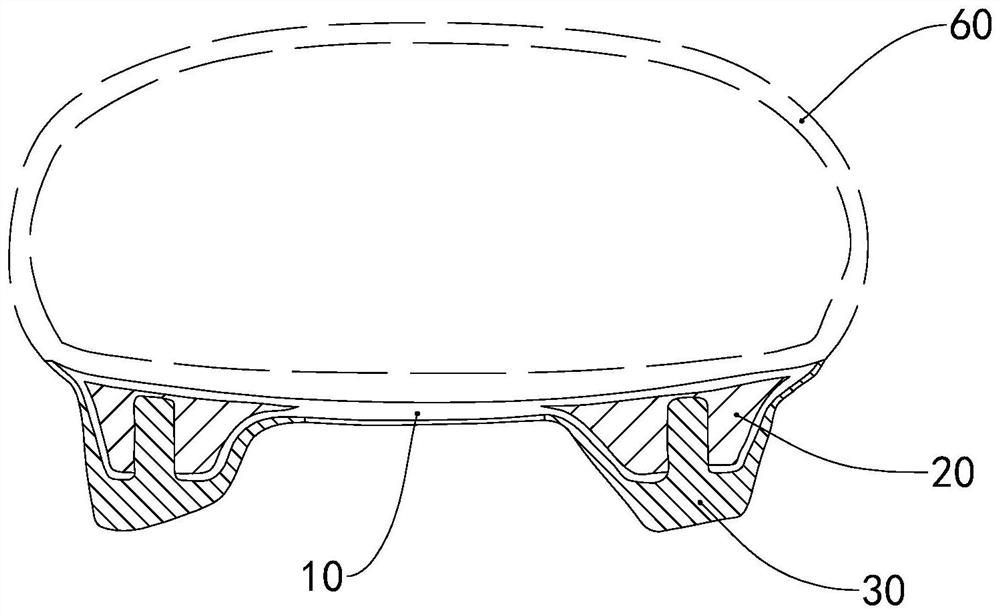

[0032] The present embodiment provides a composite molding method for a carbon fiber sports shoe sole, the method comprising the following steps:

[0033] Step 1: Prepare carbon plate 10, TPU foot nail inner nail 20, TPU foot nail outer nail 30 and carbon fiber prepreg.

[0034] Among them, the carbon plate 10 can be an existing carbon plate, which is a carbon fiber composite material, which is generally formed of epoxy resin and carbon fiber. The epoxy resin can be softened in the hot pressing process and form a specific shape with the shape of the mold cavity. shape, the carbon plate is stronger than FRP after curing. The carbon plate 10 is uncured before thermoforming, where uncured includes completely uncured or incompletely cured.

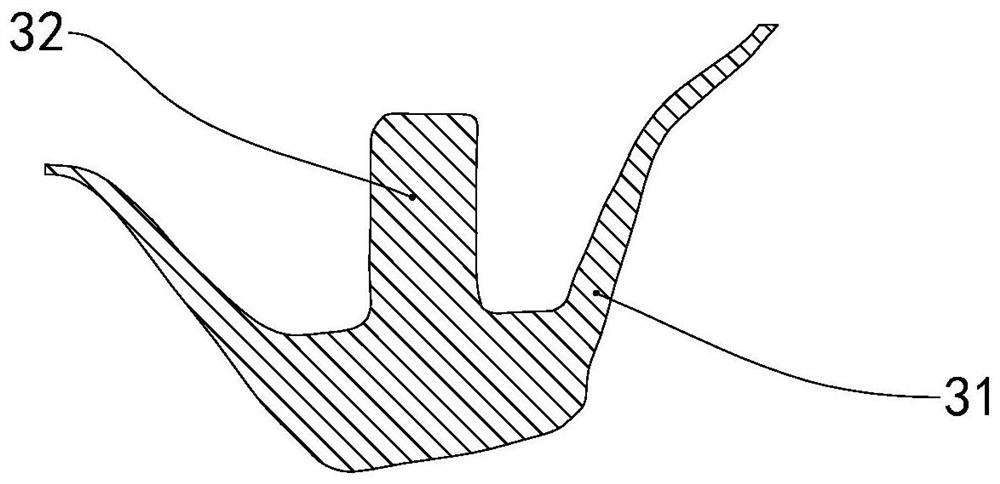

[0035] The structure of the TPU foot nail inner nail 20 is as follows figure 2 As shown, the structure of the TPU foot nail outer nail 30 is as follows image 3 shown. The TPU foot nail inner nail 20 and the TPU foot nail outer nail 30 ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com