Lead plug-in type junction box and installation method

A plug-in, junction box technology, applied in the direction of electrical components, etc., can solve the problems of no visual window for the insertion depth of wires, affecting work efficiency, and non-standard tightening screws. The effect of shortening the connection time of the meter and reducing the wiring time of the meter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

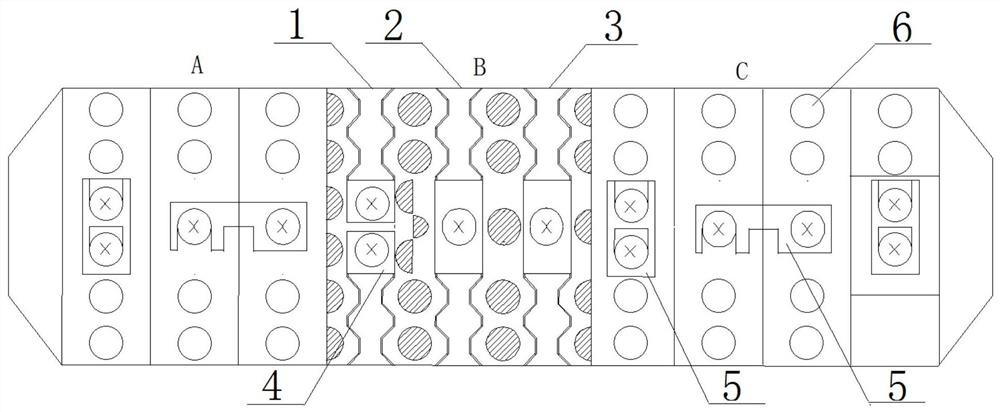

[0036] Such as figure 1 As shown, the wire plug-in junction box according to the present invention includes a junction box body, and the junction box includes three sets of voltage and current wires, which are divided into A phase, B phase and C phase from left to right, wherein B phase is set as The wire plug-in structure located inside the junction box, wherein: the wire plug-in structure includes three rows of lines arranged side by side, which are the voltage line 1, the current incoming line 2 and the current outgoing line 3, and there are plugs fixed along the placement direction of the three lines. Pull-out clip 4.

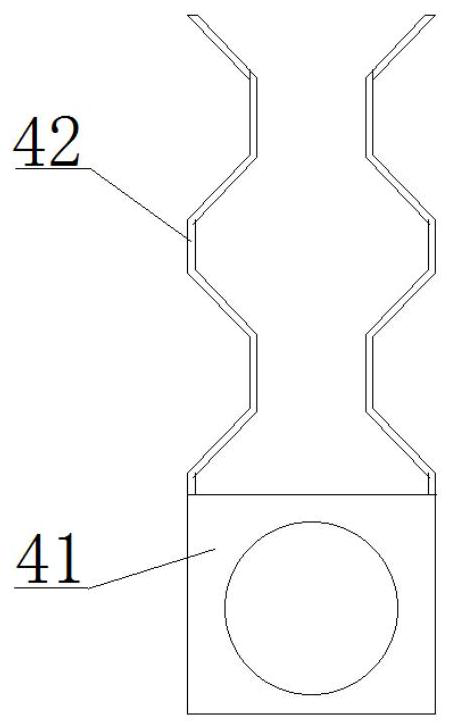

[0037] The two plug-in clips 4 on the voltage line 1 are split-type structures, including two oppositely arranged plug-in clips 4, and each side of each plug-in clip 4 is provided with a clip 42; The plug-in clips 4 on the wire 2 and the current outlet 3 are all of an integrated structure, and each plug-in clip 4 is provided with clips 42 on both sides; T...

Embodiment 2

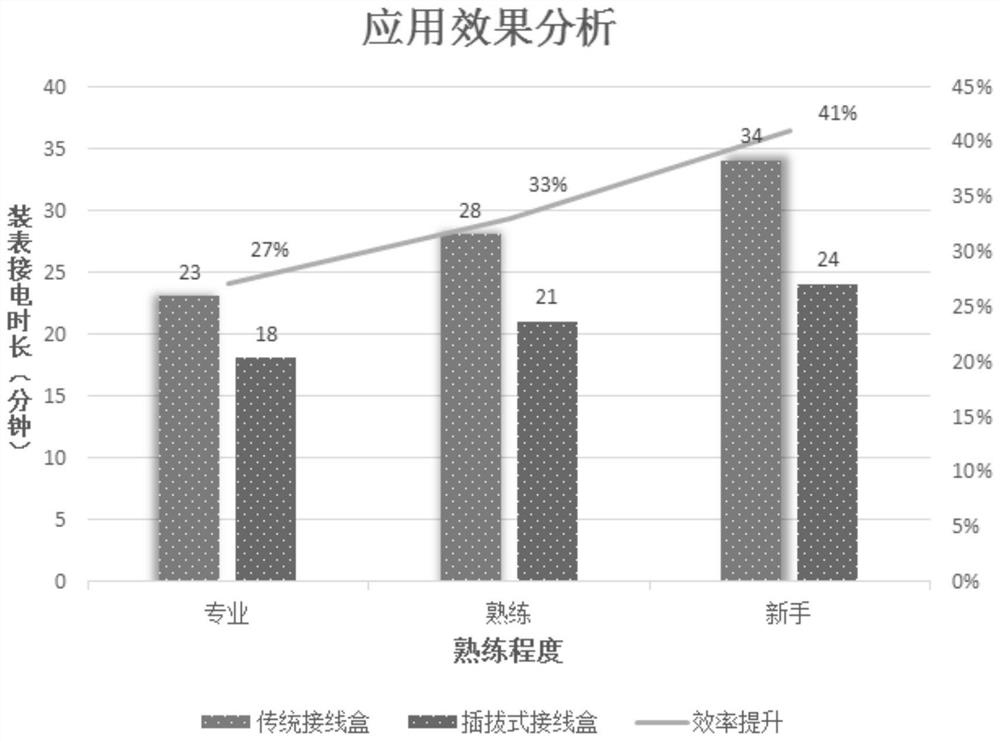

[0064] Such as image 3 As shown, the present invention proposes a wire plug-in junction box, using two clips 42 arranged longitudinally and connected to each other to form a wire fixing structure, and the wires can be directly inserted into the two clips 42 during installation. Realize the connection method of free plugging and unplugging of wires, reduce the switching rate of tools, effectively reduce the wiring time of meter installation, improve the work efficiency at the user end, and complete meter installation and power transmission for users faster. The efficiency of watch installation must be increased by at least 30%. The most effective way to improve efficiency is to reduce the time for watch installation. Therefore, the team members set the target time to 19 minutes, and the efficiency increased by 41%.

[0065] The first plug-in junction box was installed in Shandong Weifang Ao Rui Environmental Protection Co., Ltd., and the conduction of the plug-in junction box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com