In-hole directional stone crushing device adopting high-voltage electric pulse and construction method thereof

A high-voltage electric pulse and stone crushing technology, which is applied in the direction of foundation structure engineering, sheet pile walls, blasting, etc., can solve problems affecting project quality and efficiency, increase mechanical piling strength, increase working hours, etc., and achieve the goal of increasing energy Utilization rate, reduced workload, enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

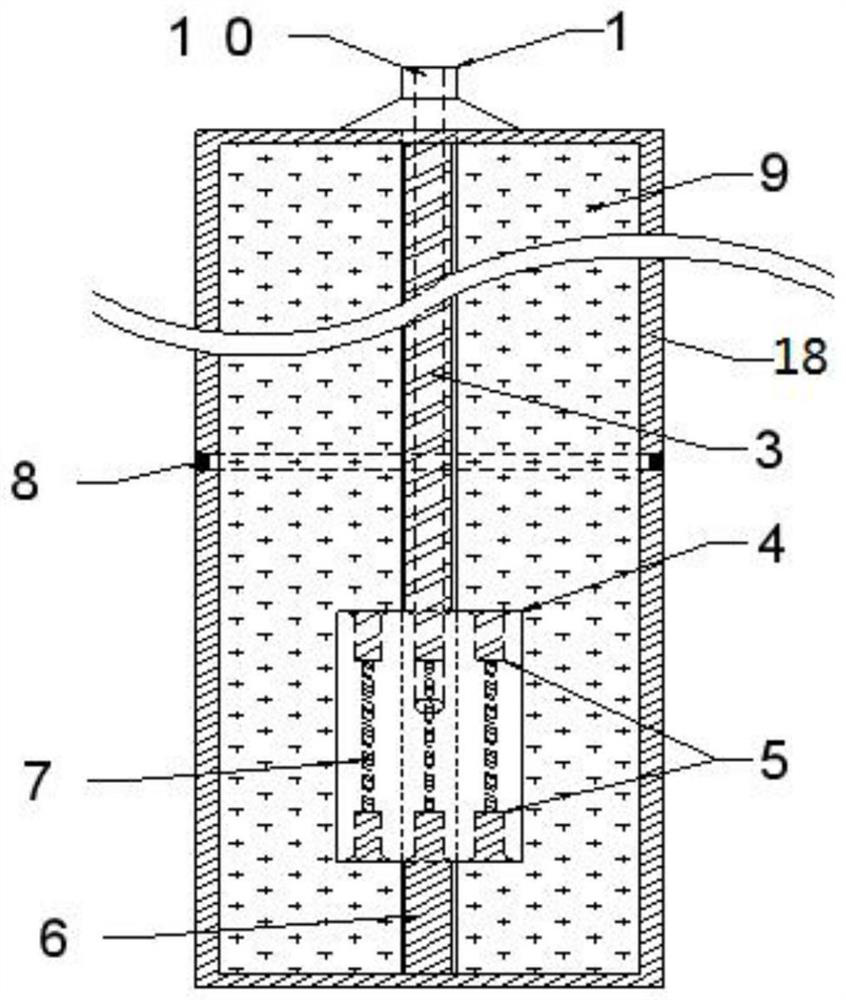

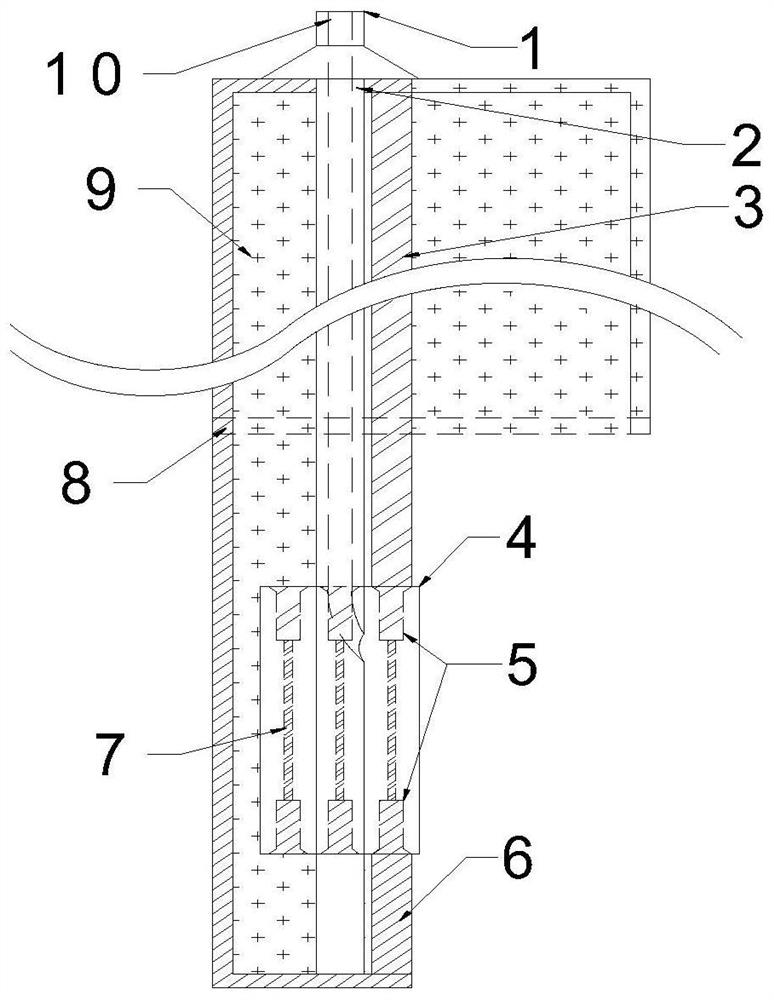

[0036] Such as Figure 1-7 As shown, an in-hole directional lithotripsy device using high-voltage electric pulses includes a device housing 18 on which a high-voltage electric pulse component, a wire replacement component, a liquid explosive injection component and an insulating The material 9 has four major parts; the insulating material 9 is filled in the inner cavity of the device housing 18, and the middle part of the device housing 18 is embedded with a sealing rubber ring 8 on the outside, and the high-voltage electric pulse assembly, wire replacement Components and some parts on the liquid explosive liquid injection assembly are biased inside the device housing 18; the liquid explosive liquid injection assembly injects the liquid mixed explosive 14 into the hole to be blasted, and the injected liquid mixed explosive 14 Located below the sealing rubber ring 8 .

[0037] Specifically, the injected liquid mixed explosive 14 refers to a mixture of liquid explosive (includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com