In-mold spraying system and process method thereof

A technology of internal spraying and mold cavity, which is applied to other household appliances, household components, household appliances, etc., can solve the problems of device differentiation, etc., and achieve the effects of high production efficiency, convenient operation and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

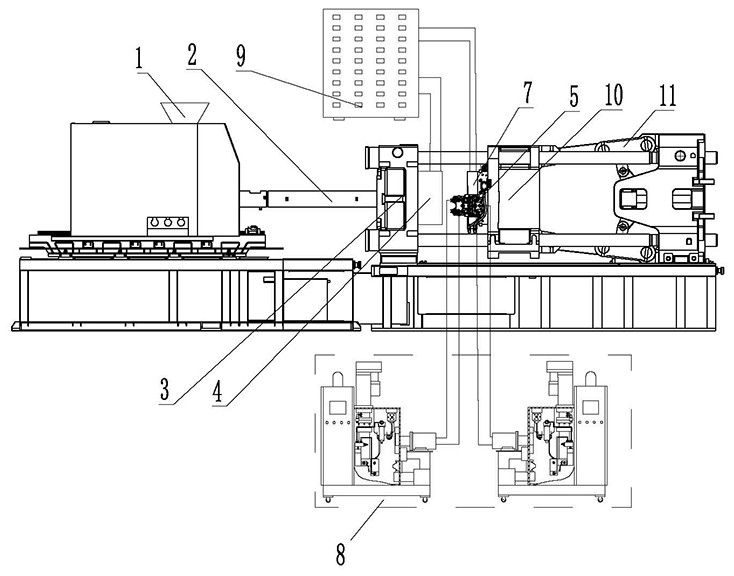

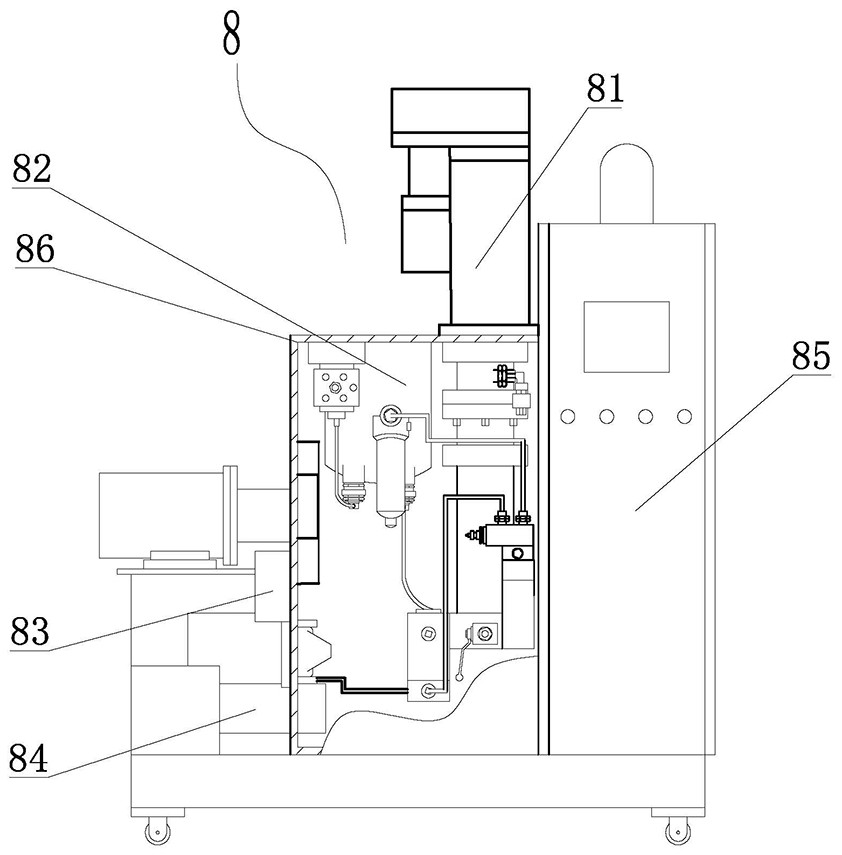

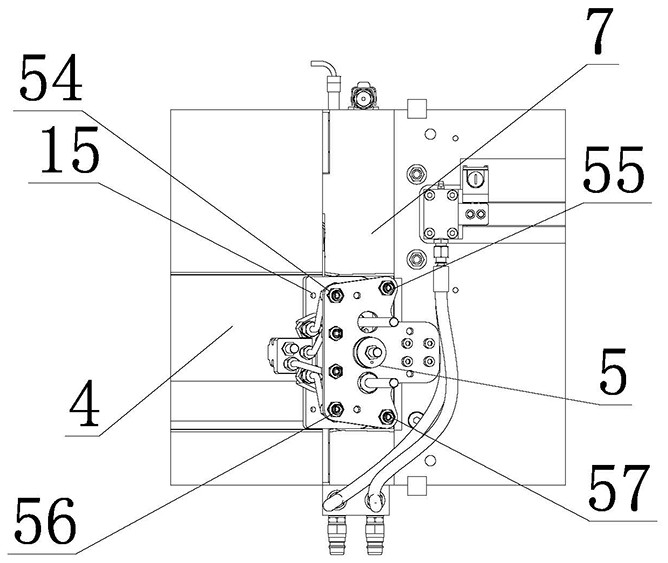

[0052] In the embodiment shown in Figure 1, an in-mold spraying system, the whole system mainly includes an injection machine 100, three half-molds, a mold temperature control unit 9, a PU injection device 8 and a double inclined mixing nozzle 5, the The injection machine 100 includes a hopper 1, an injection part 2, a front plate 3, a movable plate 10, and a mold clamping mechanism 11. The mold temperature control unit 9 controls the temperature of the three half molds to prevent the PU material from rapidly solidifying during the injection process. The three half-molds are respectively the first half-mold 4, the second half-mold 6 and the third half-mold 7, the first half-mold 4 is set on the front template 3, and the second half-mold 4 is set on the movable template 10. Half-mold 6 and third half-mold 7. Described first half mold 4 is provided with thimble 41, and ejector pin is set on the first half mold for the convenience that the workpiece that is coated with PU layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com