Iron/polydopamine/carbon composite catalyst with double properties of reduction and oxidation as well as preparation method and application of iron/polydopamine/carbon composite catalyst

A composite catalyst, polydopamine technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low catalytic performance, zero-valent iron and its composite materials. Poor stability, easy oxidation and other problems, to achieve the effect of improving catalytic performance, improving transfer efficiency, and high reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides an iron / polydopamine / carbon composite catalyst with both reduction and oxidation properties, and its specific preparation steps are as follows:

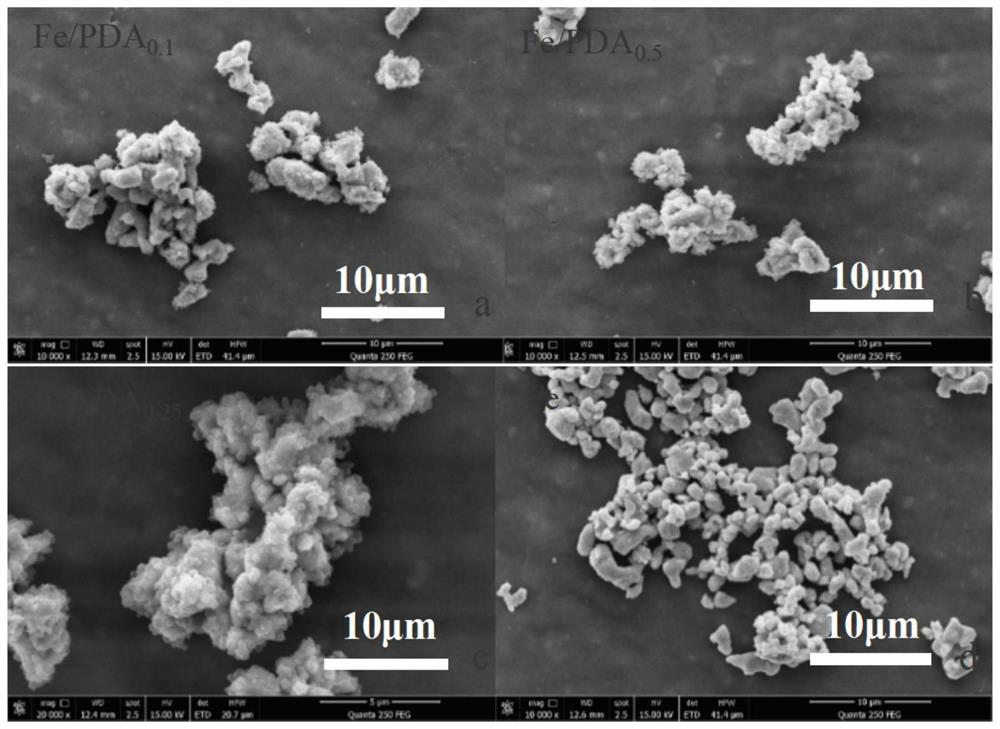

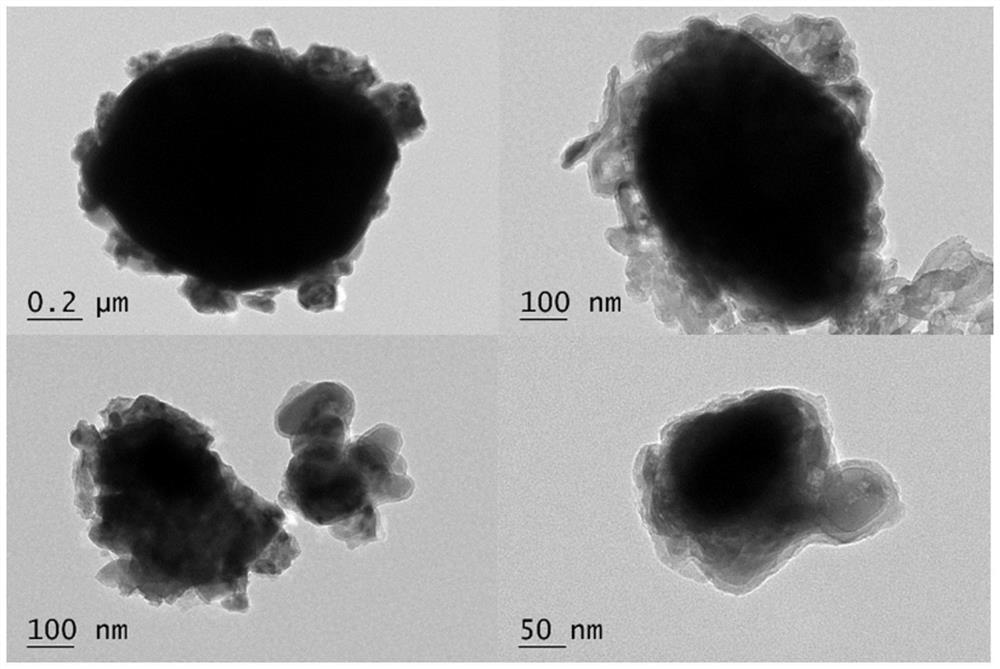

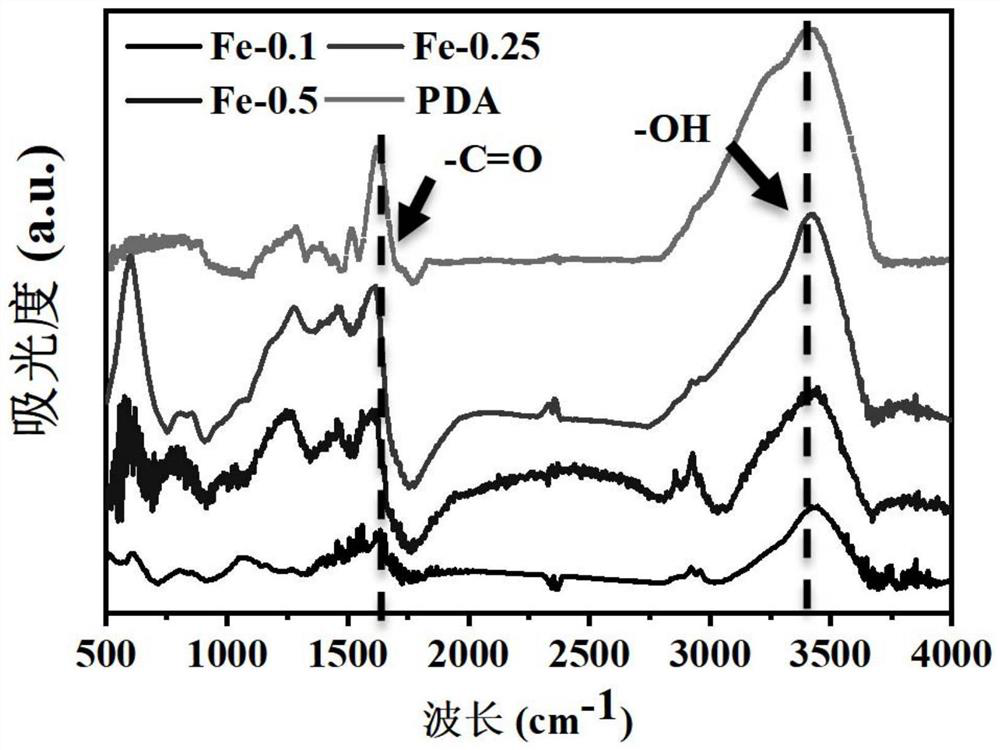

[0053] (1) Preparation of Fe / PDA composite structure: Take 1.5g of micron-sized zero-valent iron and ultrasonically disperse it in a Tris-HCl buffer solution with a pH of 8.5 and a concentration of 8mM. Under the participation of oxygen, self-polymerization was carried out for 24 hours, and after separation and washing, it was freeze-dried at -80°C for 12 hours in a vacuum environment to obtain a Fe / PDA composite structure with a core-shell structure. The mass ratio of dopamine and Fe inner core is 0.25 in the present embodiment, i.e. n=(1.59M 3 +M 2 ):M 1 = 0.25.

[0054] (2) Preparation of Fe / PDA 0.25 / C composite catalyst: take the Fe / PDA composite structure prepared in step (1) and place it under nitrogen, calcinate at 300°C for 3 hours, and obtain Fe / PDA after carbonization of the PDA surface ...

Embodiment 2

[0066] This example provides an iron / polydopamine / carbon composite catalyst with dual properties of reduction and oxidation. The specific preparation steps are basically the same as those in Example 1. The main differences between the two are:

[0067] 1) n=0.1 of the present embodiment, the prepared catalyst is Fe / PDA 0.1 / C composite catalyst.

Embodiment 3

[0069] This example provides an iron / polydopamine / carbon composite catalyst with dual properties of reduction and oxidation. The specific preparation steps are basically the same as those in Example 1. The main differences between the two are:

[0070] 1) n=0.5 of the present embodiment, the prepared catalyst is Fe / PDA 0.5 / C composite catalyst.

[0071] Embodiment 1~3 is compared, as Figure 5 , 7 As shown in and 9, when n=0.25, the degradation performance of the composite catalyst is optimal, combining Figure 9 Analysis of its electron transfer efficiency found that Fe / PDA 0.25 The / C composite catalyst is about 5 times higher than that of pure iron, which greatly accelerates the degradation rate. When the proportion of polydopamine continues to increase, the electron transfer efficiency of the catalyst is almost saturated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com