Process method for installing two-section magnet yoke of hydraulic generator

A technology for hydroelectric generators and installation methods, which is applied in the direction of electromechanical devices, electrical components, manufacturing stator/rotor bodies, etc., can solve problems such as a large number of installation tools, harmful deformation of the upper yoke, and long straight-line installation time limit, etc., and achieve installation quality The effect of improving, reducing the installation period, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

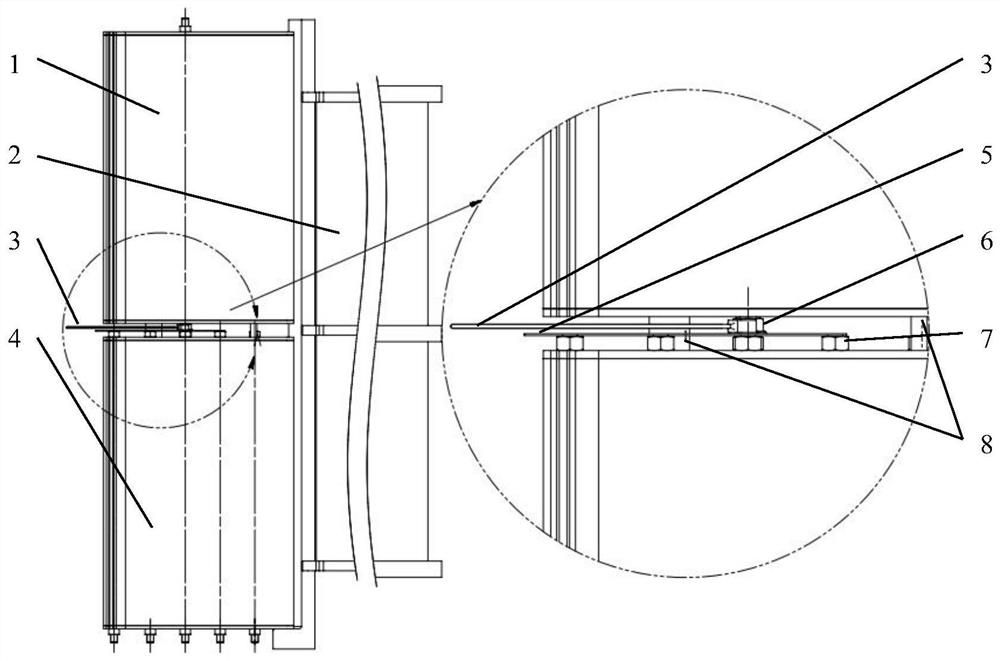

[0019] Such as figure 1 , figure 2 As shown, the present invention provides a process method for installing a two-stage yoke of a hydro-generator, which can complete the installation of the two-stage yoke without jacking up or falling back the upper yoke, saving the cost of installation tools and reducing labor intensity , Reduce the installation cycle and improve the installation quality. Technical scheme of the present invention is:

[0020] 1) Stack the lower yoke 1 on the rotor bracket 2, use positioning pins, lamination keys, etc. for positioning, and continuously adjust the roundness and height of the lower yoke 1 as the height of the lamination increases;

[0021] 2) Use the pneumatic wrench to compress the lower yoke 1 every 600mm height;

[0022] 3) After the lamination reaches the final height of the lower yoke 1, the lower yoke 1 is finally compressed by a hydraulic tensioner.

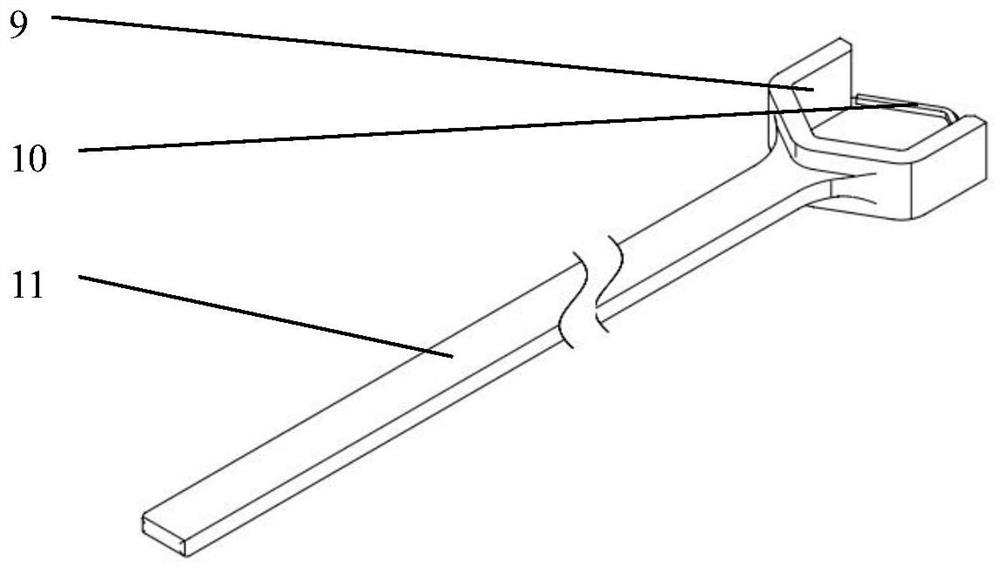

[0023] 4) Install the inter-segment support block 8 of the yoke, measure the actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com