Feeding system hoisting mechanism

A technology of feeding system and feeding device, which is applied in cranes, hoisting devices, transportation and packaging, etc., can solve the problems of difficult work, easy dripping, excessive energy consumption, etc., and achieves easy operation and maintenance, good Cooperate and facilitate the effect of feeding system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The hoisting mechanism of the feeding system of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

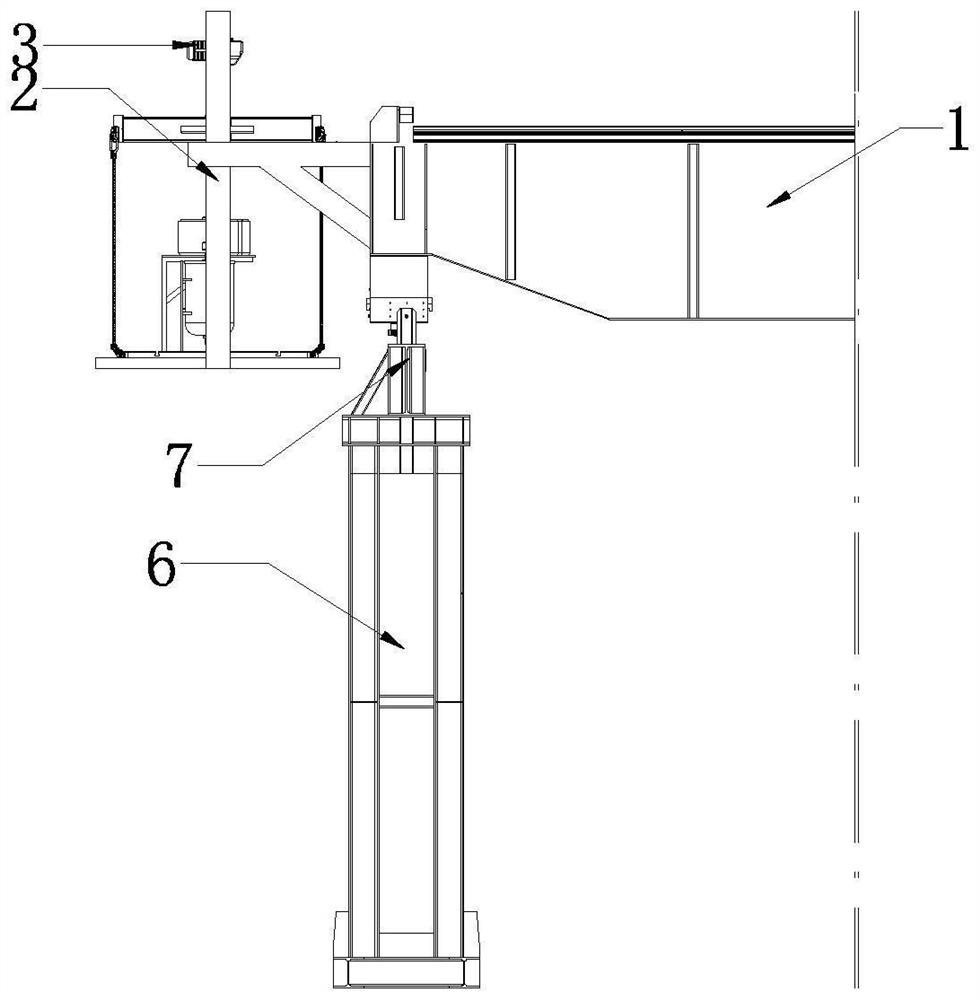

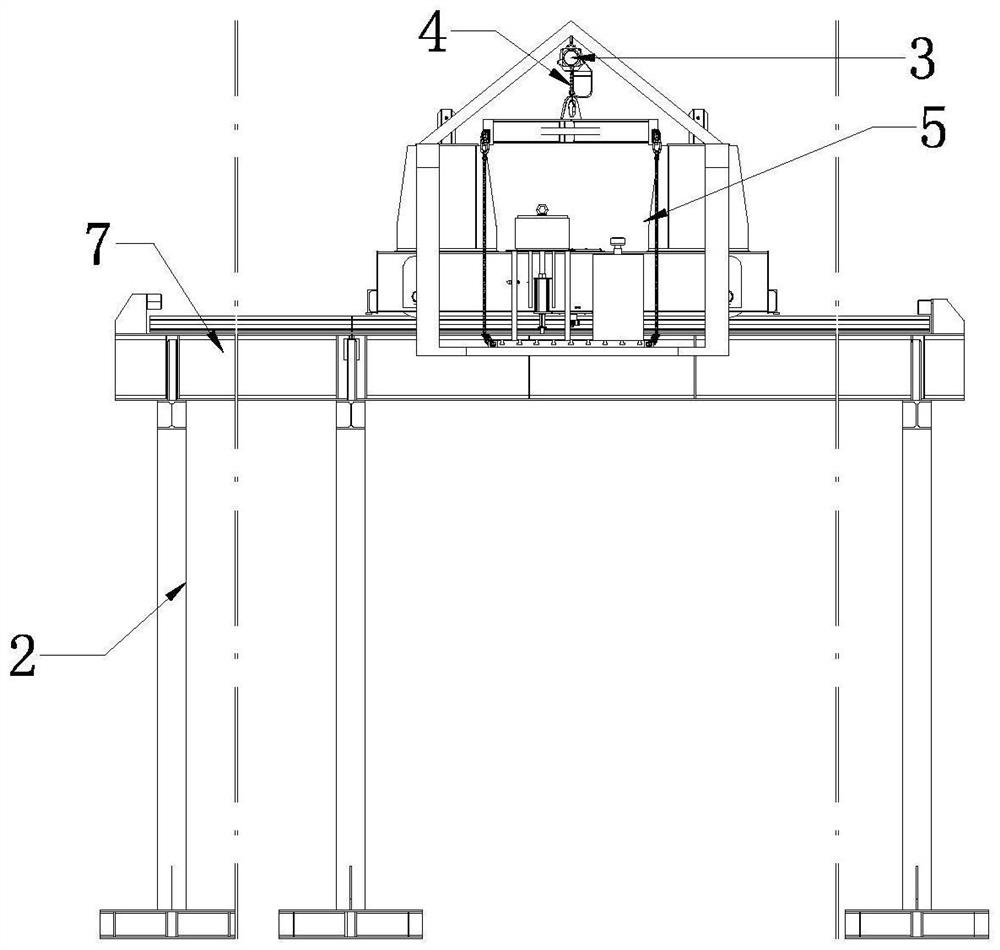

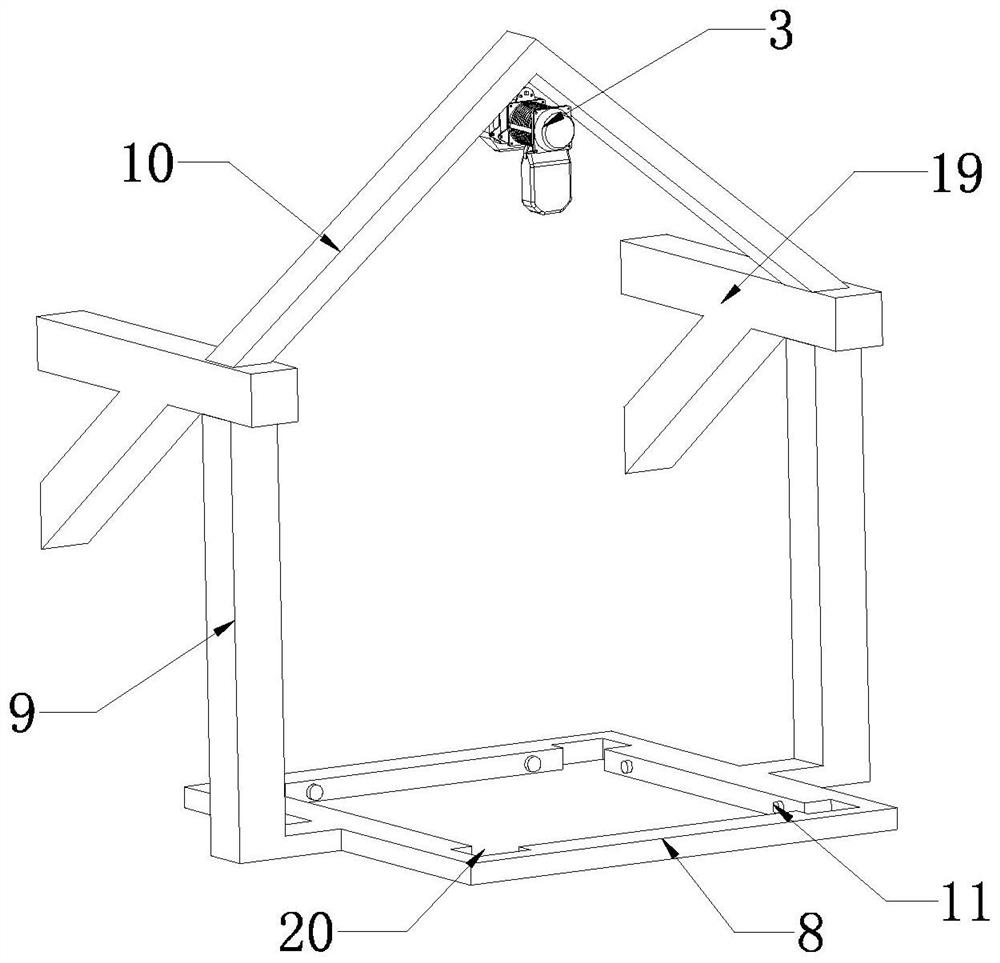

[0021] For the automatic painting operation in the factory building of large bridges, as mentioned in the background technology, it is usually necessary to install the painting robot on the crane so that the painting robot can move back and forth in the factory building to achieve painting. The feeding system of the present invention is hoisted The mechanism is a new solution to the defect that the existing feeding system is fixed on the main body of the crane-type painting robot. As shown in the figure, it includes a hoisting bracket fixedly installed on the left end of the upper beam 1 of the crane 2 and the remote control electric hoist 3 fixedly installed on the top of the hoisting bracket 2, and the upper beam 1 is equipped with a figure 1 The left-right direction of the directions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com