Elastic pre-tightening terminating stepless multidirectional large floating interconnection structure

An elastic pre-tightening and interconnection structure technology, which is applied in the direction of connection, contact parts, and parts of the connection device, can solve the problem of inability to achieve a wide range of axial floating, the inability to meet the floating amount of interconnection structures, metal panels and connections In order to achieve stable and reliable elastic modulus, wide application value and simple and reliable part structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following, in conjunction with the accompanying drawings and preferred embodiments, will discuss the elastic preload terminal stepless multi-directional large floating interconnection structure proposed according to the present invention. Specific embodiments, structures, features and effects thereof are described in detail below.

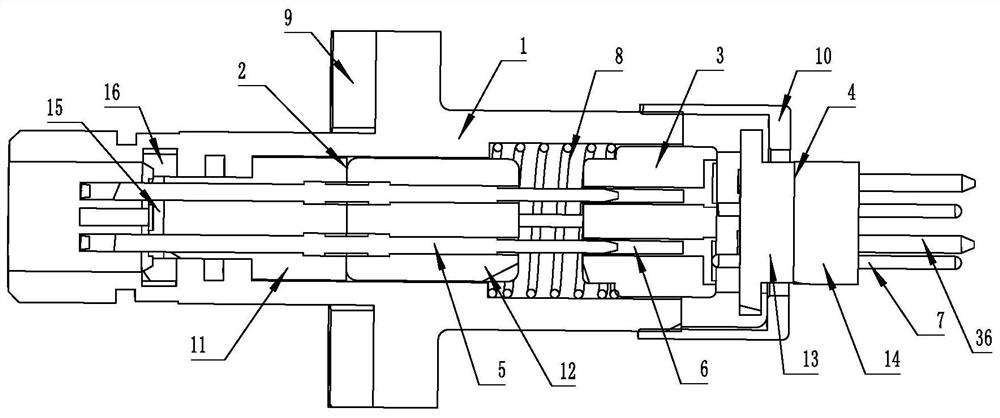

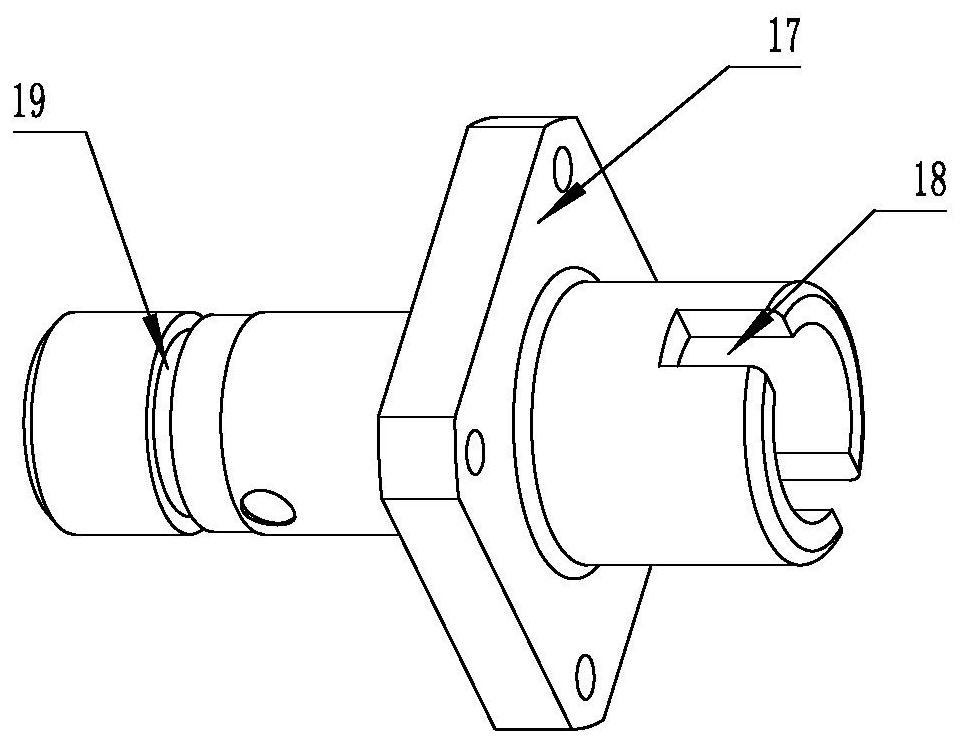

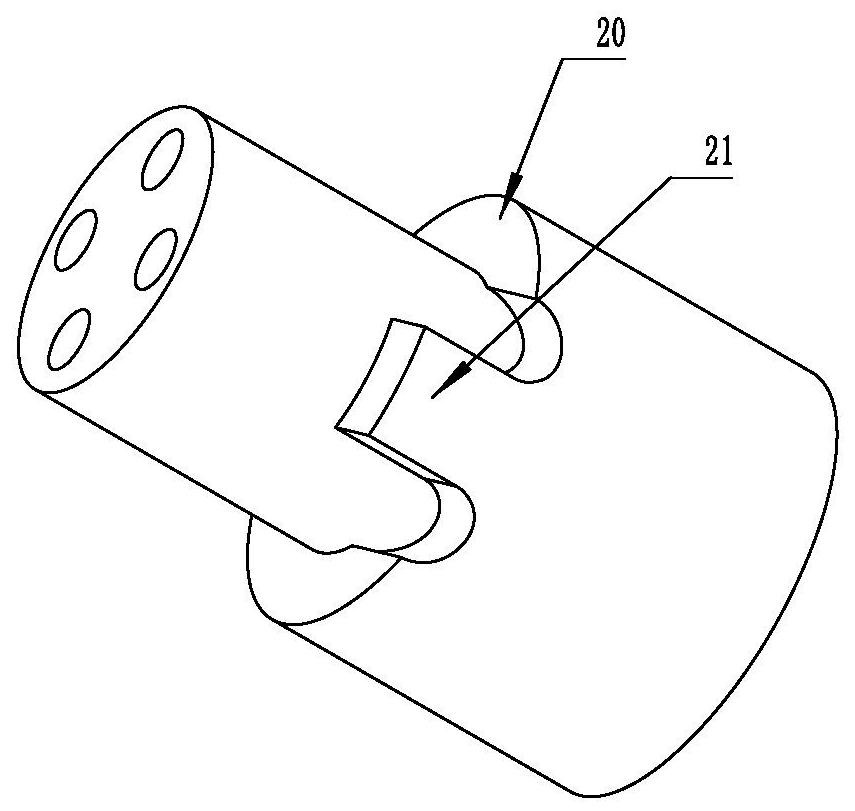

[0076] see Figure 1-12 , which is a structural schematic diagram of each part of the elastic pre-tightening terminal stepless multi-directional large floating interconnection structure of the present invention, the structure includes a housing 1, and the front insulator is sequentially installed in the housing 1 along its axial direction from front to back 2. The floating insulator 3 and the bottom insulator 4, wherein the front insulator 2 is fixedly assembled in the casing 1, the floating insulator 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com