Triangular fixed post insulator

A post insulator and fixed technology, applied in the field of triangular fixed post insulators, can solve the problems of excessive wire sag, discharge to the ground, damage to the internal structure of the wire due to wire tension, etc. Work Intensity and Cost Funding Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

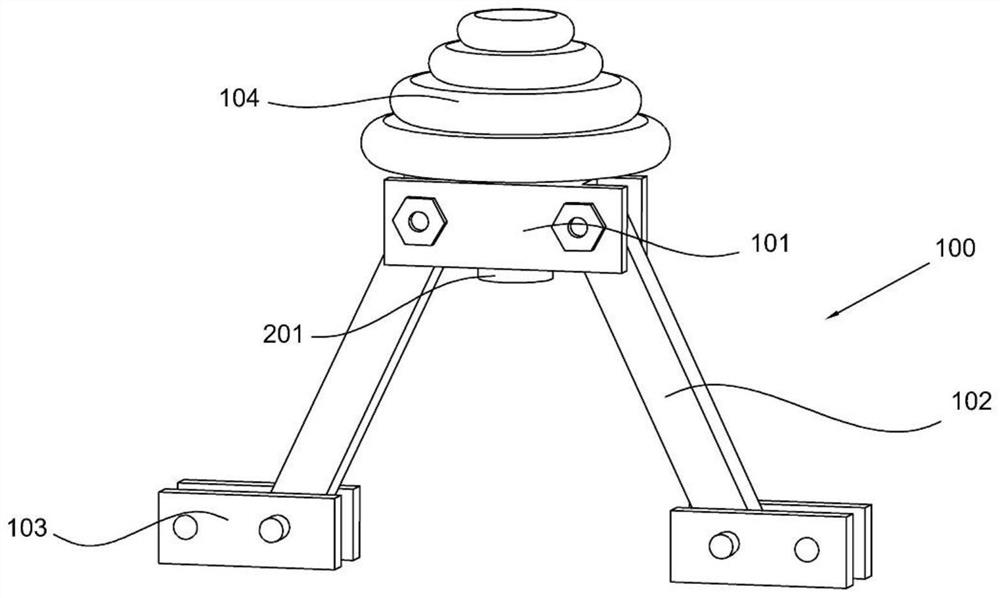

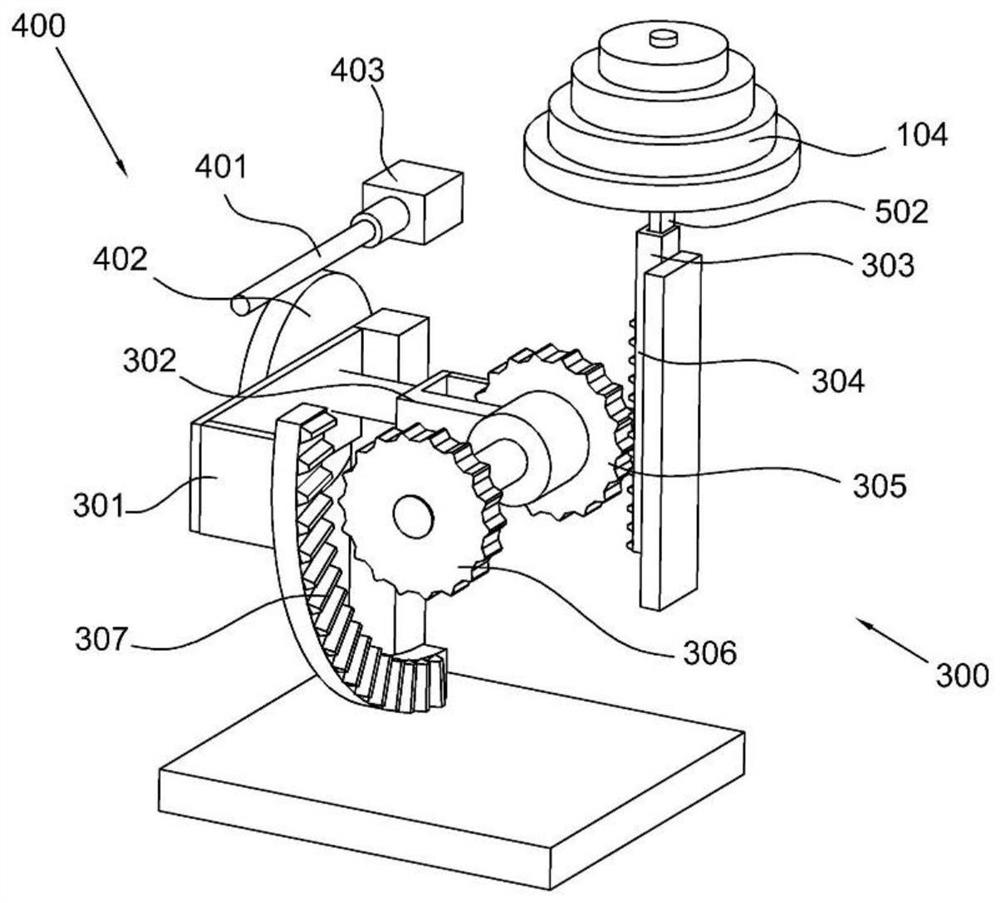

[0028] refer to Figure 1-4 , a triangular fixed post insulator, including a bracket main body 100. In this embodiment, the bracket main body 100 is a component arranged on a cross arm for support. The bracket main body 100 includes an intermediate block 101 connected with an insulator 104, The middle block 101 is block-shaped in shape, made of stainless steel or alloy steel, and its own hardness is relatively large. The two ends of the middle block 101 are also rotatably connected with support rods 102. There are two support rods 102, and the rotation of the support rods 102 The plane is a vertical plane, and a foot piece 103 is also hinged at the lower end of the support rod 102, and the foot piece 103 is threadedly connected with the cross arm.

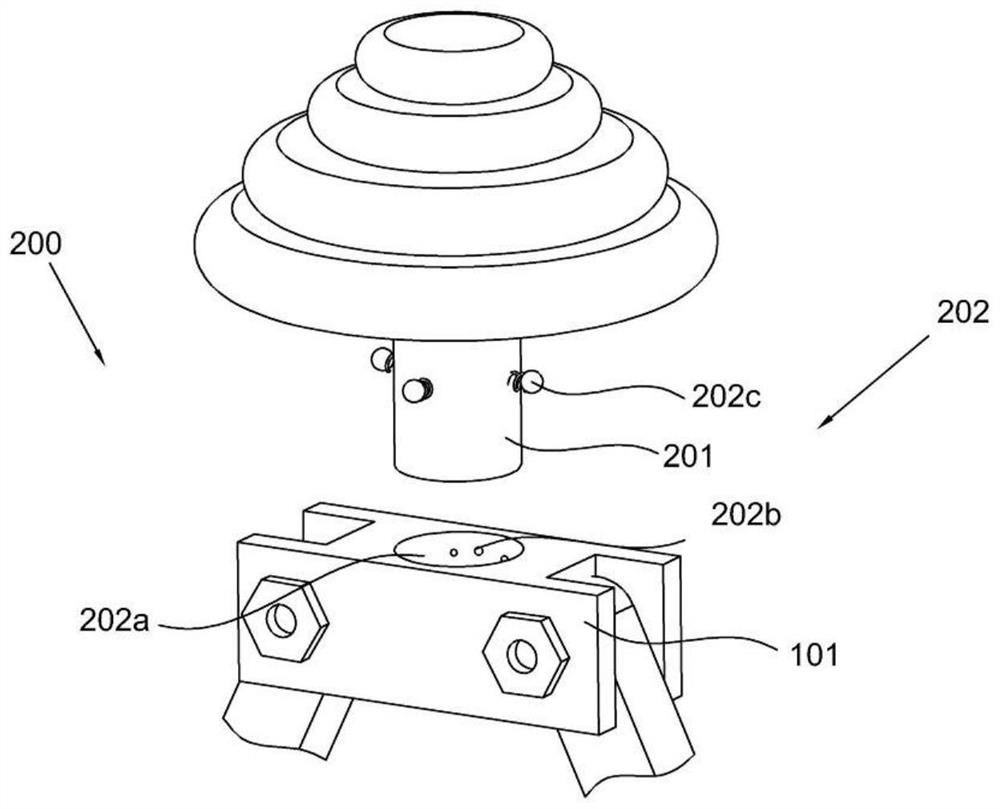

[0029] Further, the present invention also includes a mounting assembly 200. In this embodiment, the mounting assembly 200 includes a connecting rod 201 slidably connected to the middle block 101 and a locking member 202 arranged o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com