Air tightness inspection method and device

An air tightness inspection and leak detector technology, applied in the aviation field, can solve the problems of inability to accurately identify the leaking riveting area, long detection time, and inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

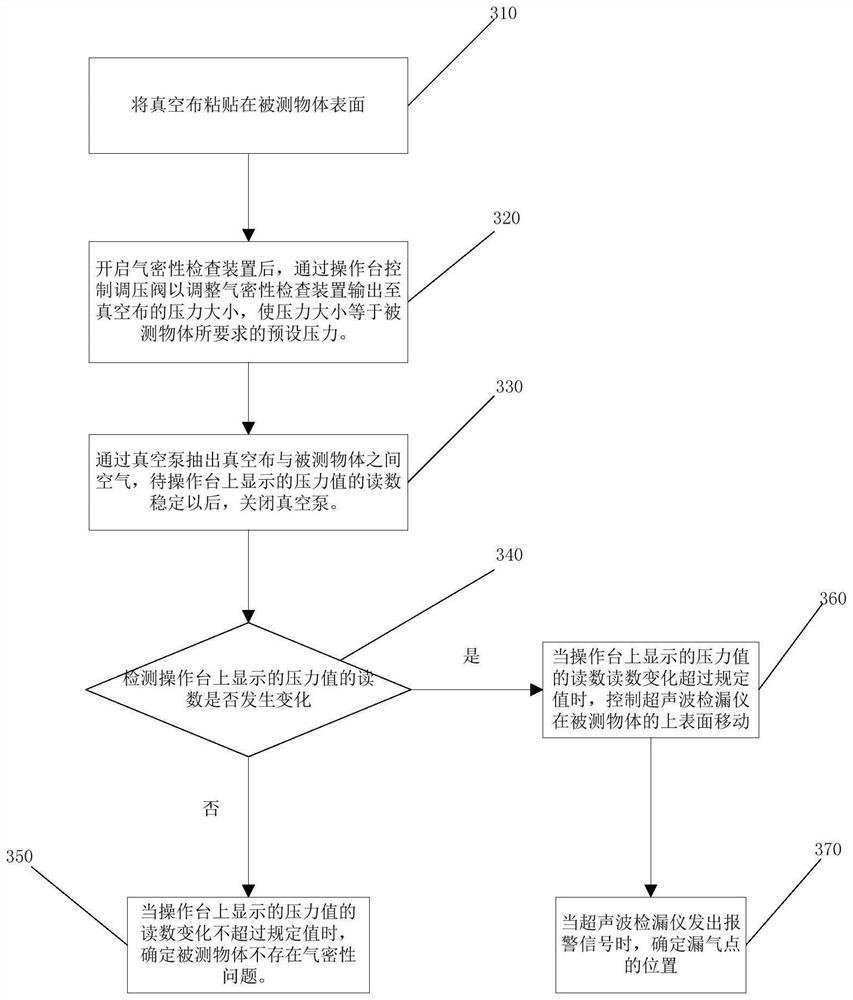

[0027] The present application will be further described in detail below through specific implementation modes in conjunction with the accompanying drawings.

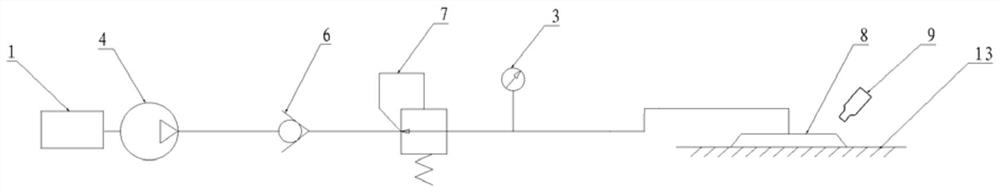

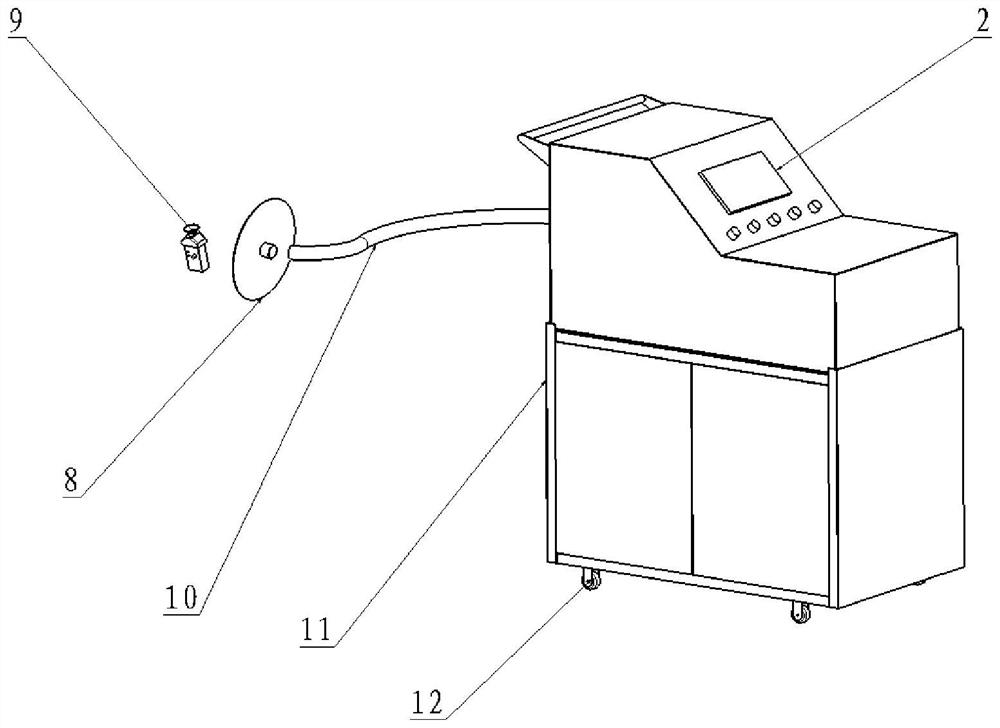

[0028] The application provides an air tightness inspection device, such as figure 1 As shown, the device includes: a power supply 1, a vacuum pressure gauge 3, a vacuum pump 4, a one-way valve 6, a pressure regulating valve 7, a vacuum cloth 8, an ultrasonic leak detector 9, connecting hoses, an operating table and a processor.

[0029] Wherein, one end of the vacuum pump 4 is electrically connected to the power supply 1, the other end of the vacuum pump 4 is mechanically connected to one end of the one-way valve 6, and one end of the pressure regulating valve 7 is connected to the one-way valve 6. The other end of the pressure regulating valve 7 is connected in parallel with the vacuum pressure gauge 3, and the other end of the pressure regulating valve 7 is mechanically connected with the vacuum cloth 8 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com