Micro pressure optical measurement method and calibration device

A calibration device and pressure testing technology, which is applied to measuring devices, fluid pressure measurement using optical methods, measuring fluid pressure, etc., can solve problems such as the difficulty of accurate measurement of micro pressure and the contradiction of dynamic response, so as to achieve accurate measurement and calibration, and improve Sensitivity and precision, and the effect of increasing the optical path length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further detailed in connection with the accompanying drawings and examples. In this embodiment, the present invention is predicted, and a specific embodiment is given, but the scope of the invention is not limited to the following examples.

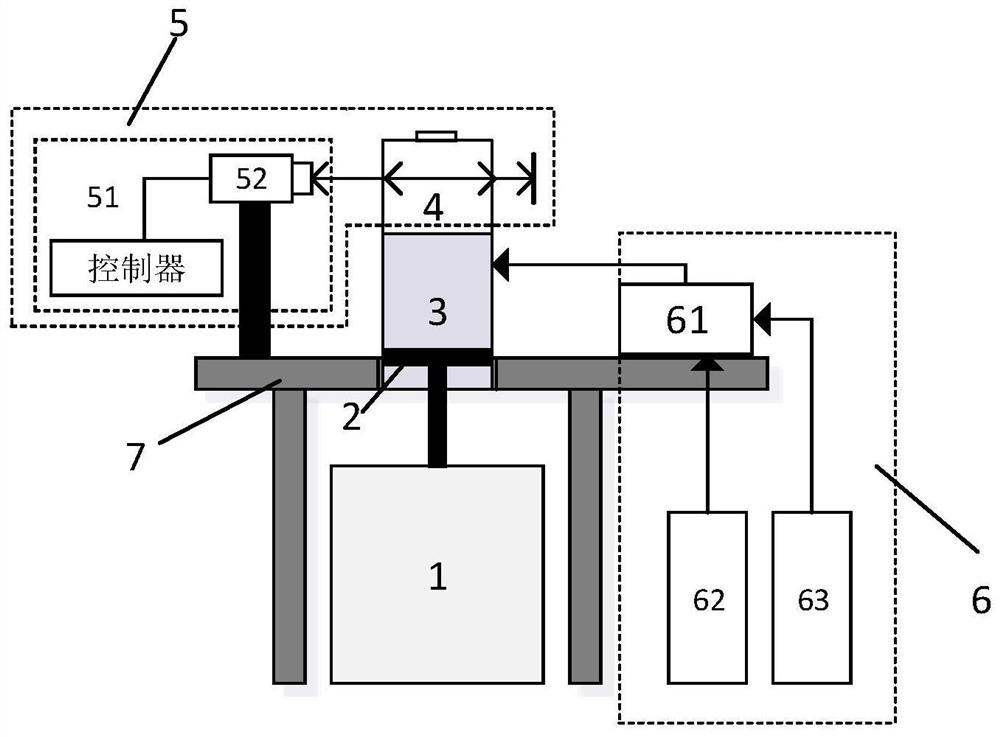

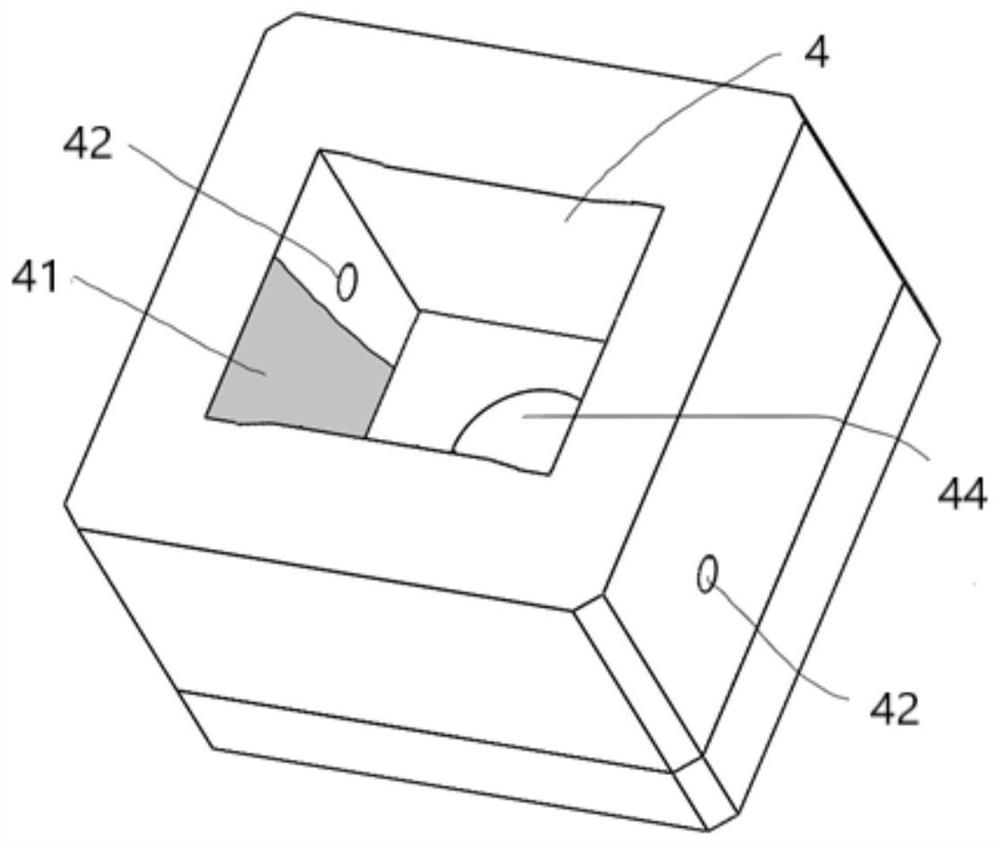

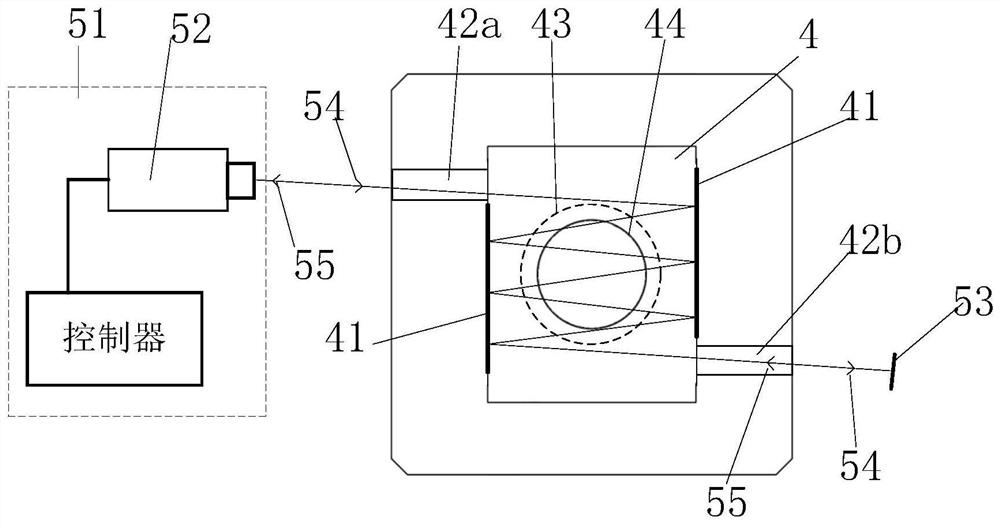

[0033] Such as figure 1 As shown, the microphilic optical measuring device disclosed herein is mainly composed of a vibration table 1, a piston 2, a variable barrier mechanism 3, a pressure test chamber 4, a laser interference measuring system 5, and a control system 6;

[0034] The pressure test chamber 4 is connected to the variable barrier mechanism 3, inner communication, the vibration table 1 is connected to the piston 2 rod, the piston 2 is in-depth variable barrier mechanism 3, and the pressure regulating mechanism 61 is connected to the vapor volume 3 for debugging volume mechanism 3. Static initial pressure. The vibrating table 1 motion drive variable allerge mechanism 3 changes its inner pressure cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com