Micro-miniature electric fuel pump post-pumping pulsating pressure monitoring system and monitoring method

An electric fuel pump and pressure monitoring technology, which is applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of unmonitored pressure pulsation after the pump, pressure pulsation cannot be monitored, etc., to improve real-time performance and accuracy, improve The effect of monitoring accuracy and improving communication quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

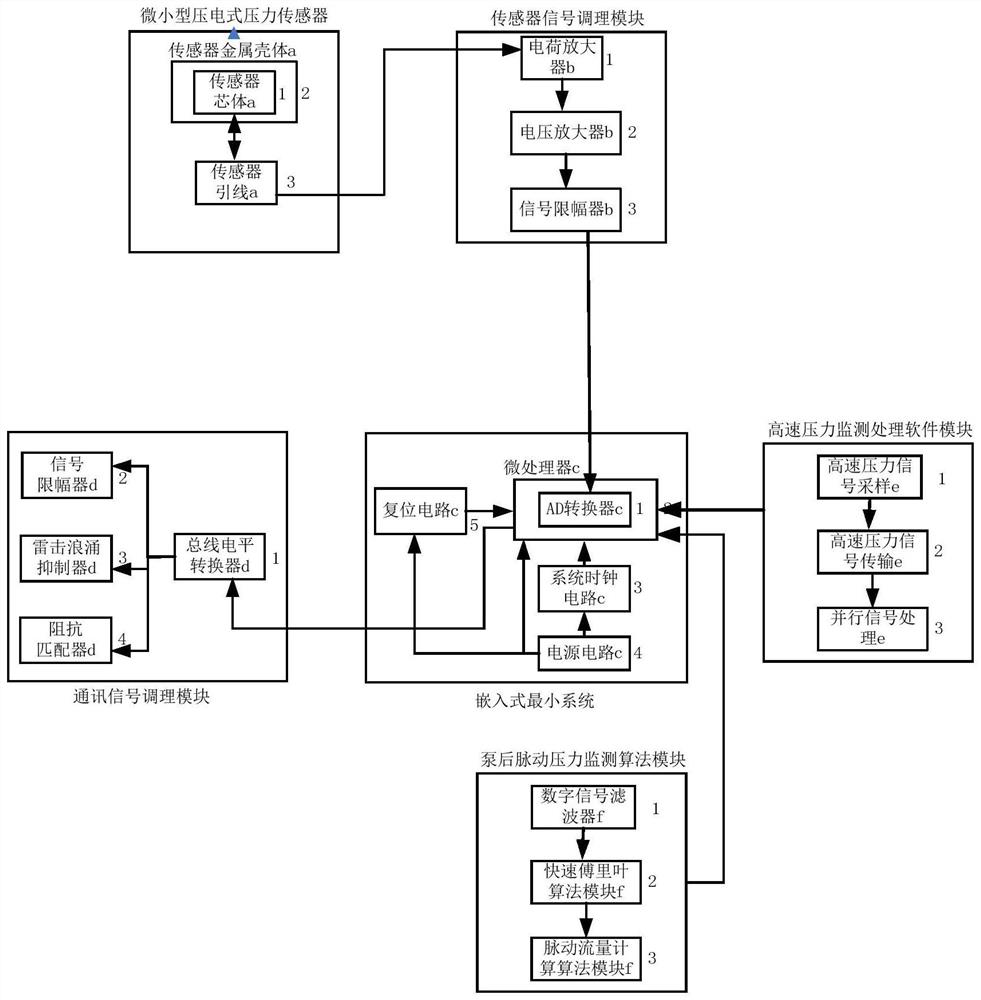

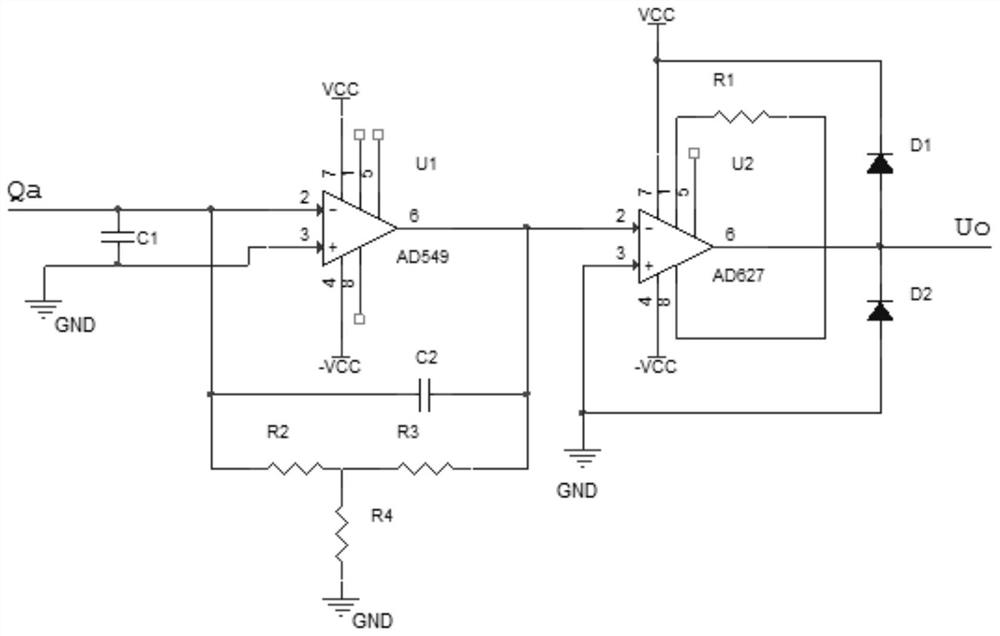

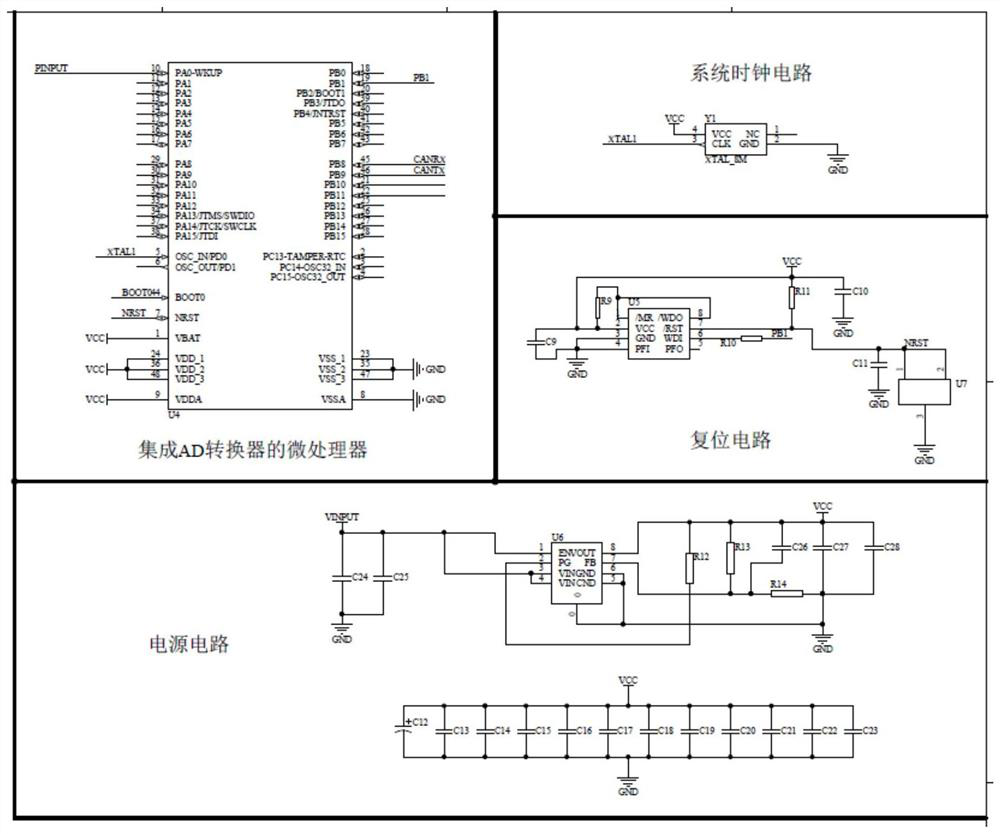

[0040] Referring to the accompanying drawings, the present invention provides a pressure monitoring system and monitoring method after a miniature electric fuel pump, which uses a high-precision and high-frequency response pressure sensor, a parallel method for high-speed data acquisition and processing, and a digital signal processing method to solve the problem of existing aviation problems. The electric fuel pump system has the problem that the pressure pulsation after the pump is not monitored or the pressure pulsation after the pump cannot be monitored at high speed. By adopting the system and method of the present invention, accurate monitoring of the pressure pulsation behind the aviation electric fuel pump at full speed can be realized, providing a basis for accurate measurement and control of the flow rate of the electric fuel pump.

[0041] like figure 1 As shown, a kind of miniature electric fuel pump pump pressure monitoring system of the present invention comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com