Primer press-fitting system and method

A press-fitting and primer technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of real-time pressure and depth monitoring in the press-fitting process, unqualified press-fitting, etc. Probability, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

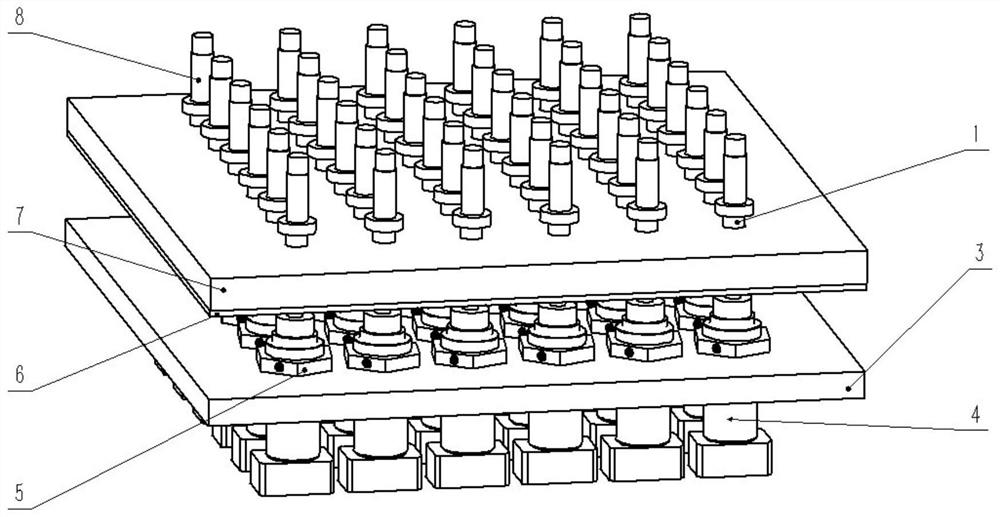

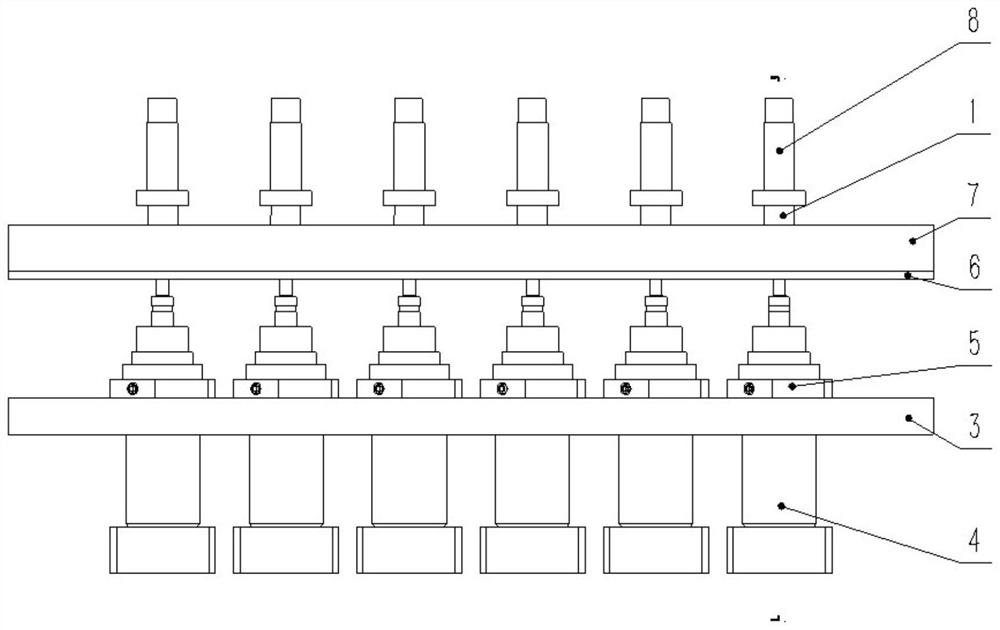

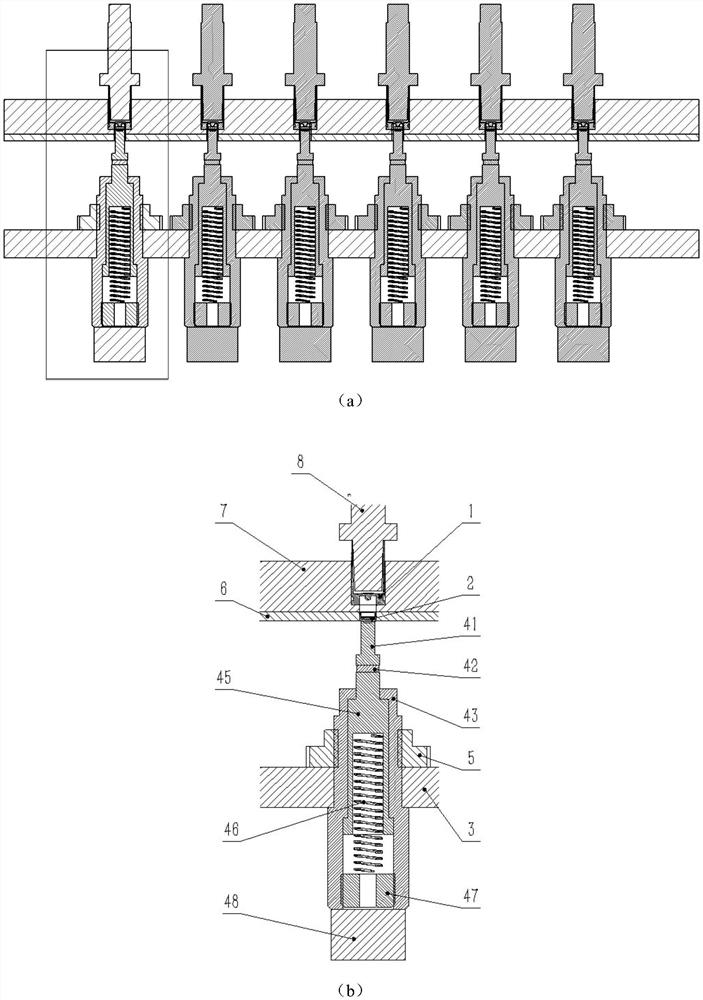

[0055] The present invention provides an embodiment, a primer press-fitting system, including: a press-fit mechanism, a pressure collection mechanism, a displacement collection mechanism, and a control mechanism. The press-fit mechanism pushes the primer into the cartridge case to complete the press-fit; The real-time press-fitting pressure during the process; the displacement acquisition mechanism collects the real-time press-fit depth during the press-fit process; the control mechanism gives feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com