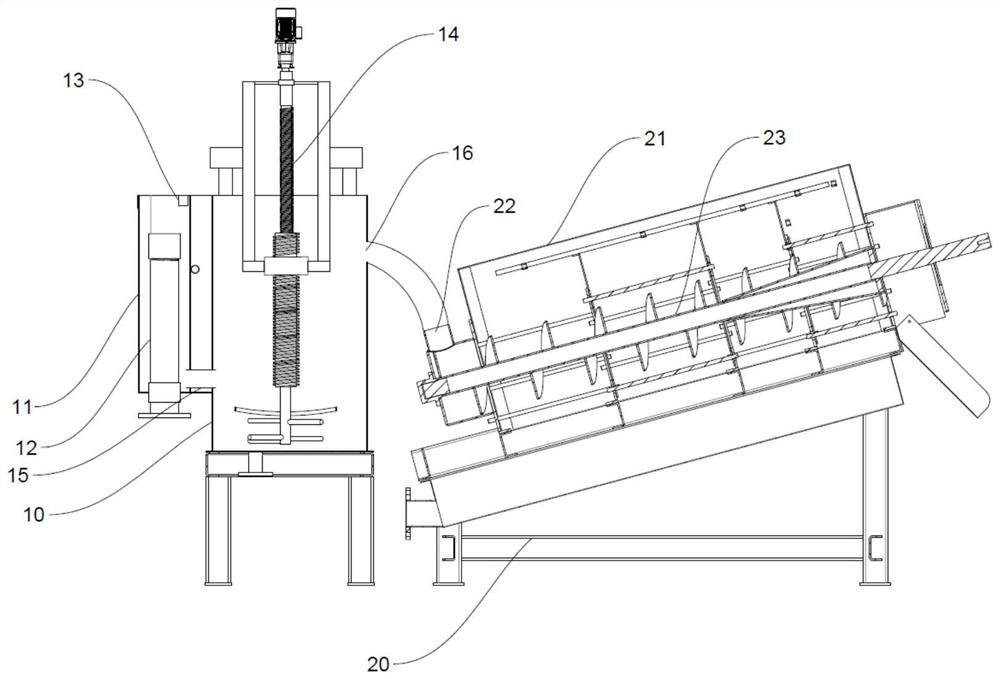

Composite sludge dewatering treatment method and equipment thereof

A sludge dehydration and treatment equipment technology, applied in water/sludge/sewage treatment, sludge treatment, water treatment parameter control, etc., can solve the problems of reducing sludge dehydration efficiency, easy sedimentation, and smaller sludge volume, etc. Achieve the effect of improving sludge dewatering efficiency, increasing flocculation speed, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

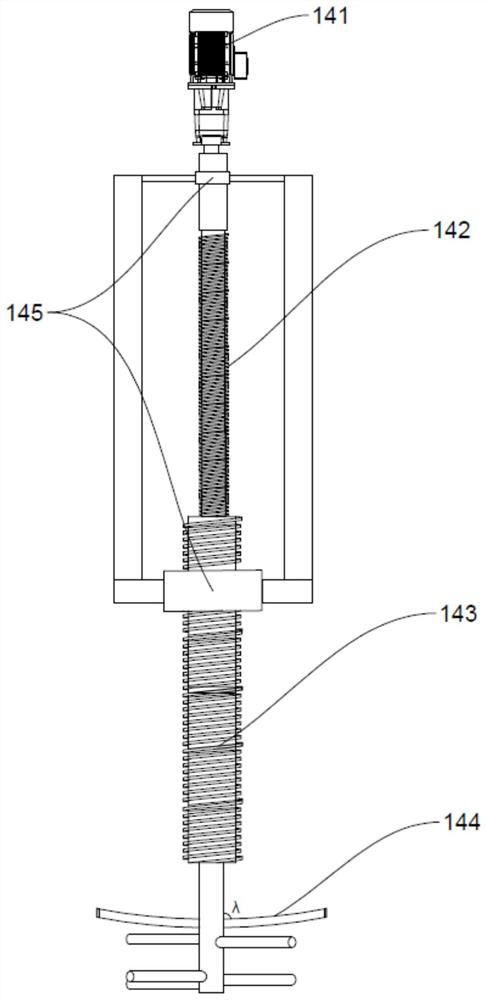

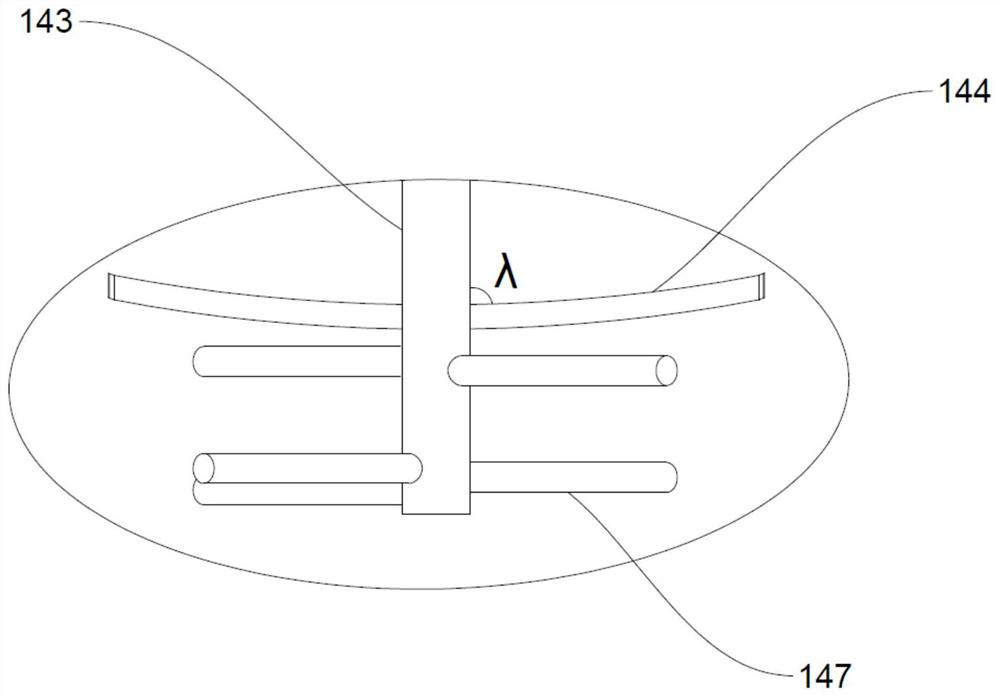

[0035] In order to solve the problems existing in the prior art, the applicant conducted an in-depth analysis on various existing solutions, as follows:

[0036] In the process of sludge dehydration of the sludge produced in the paint sewage system, the field test shows that only one sludge flocculant is added, the flocculation effect is not very good, the sludge cannot be flocculated into agglomerates, and the particles are small; so it is necessary Add caustic soda to the sludge to adjust the pH to slightly alkaline, and then add flocculant. During the reaction, in order to speed up the flocculation, the stirring paddle will be used for stirring, and the sludge will form agglomerates and form large particles. Although the flocculation effect has been improved, due to the large size of the flocs, the large-grained flocs are not only affected by their own gravity, but also by the centrifugal force of the stirring paddle, so some large-grained flocs are easy to settle; The slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com