Bearing, swing bearing, and swing bearing device for reciprocating motion

An outer bearing and inner bearing technology, applied in the field of swing bearings, machine tools, and reciprocating swing bearing devices, can solve the problems of high production cost, and the swing bearing cannot be adaptively adjusted to prolong its life, and achieves improved accuracy and contact stress. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0105] first embodiment

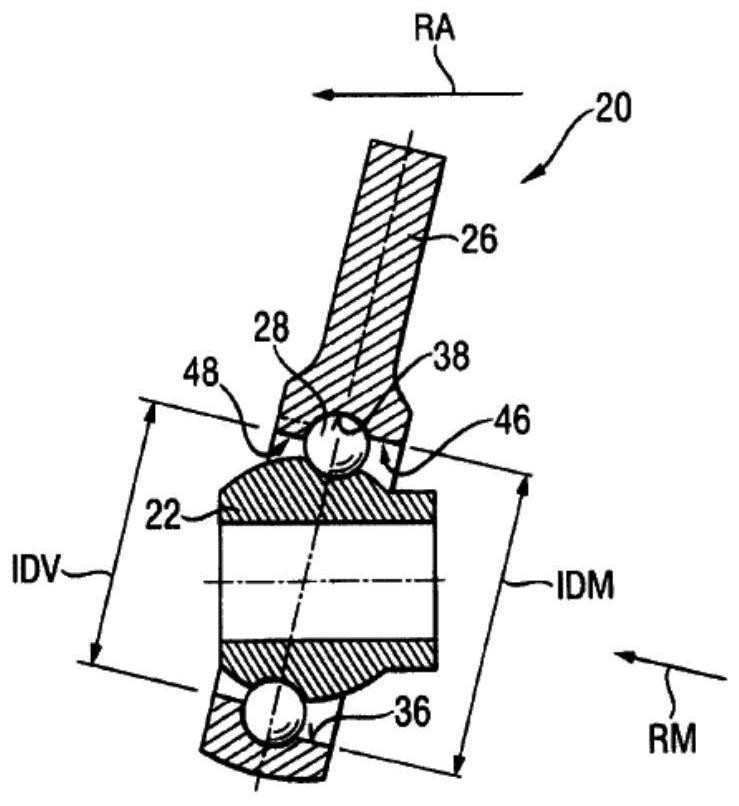

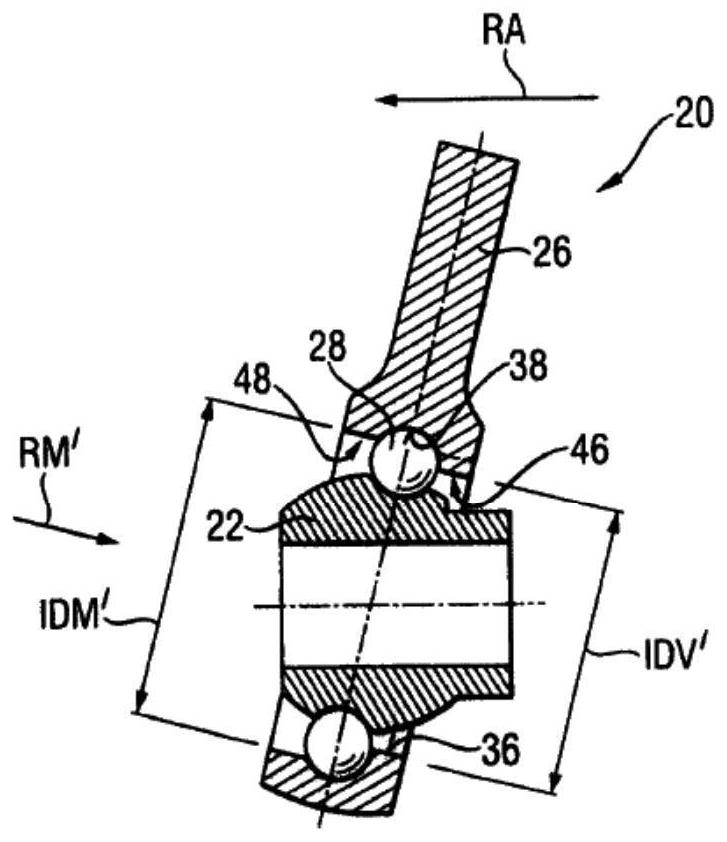

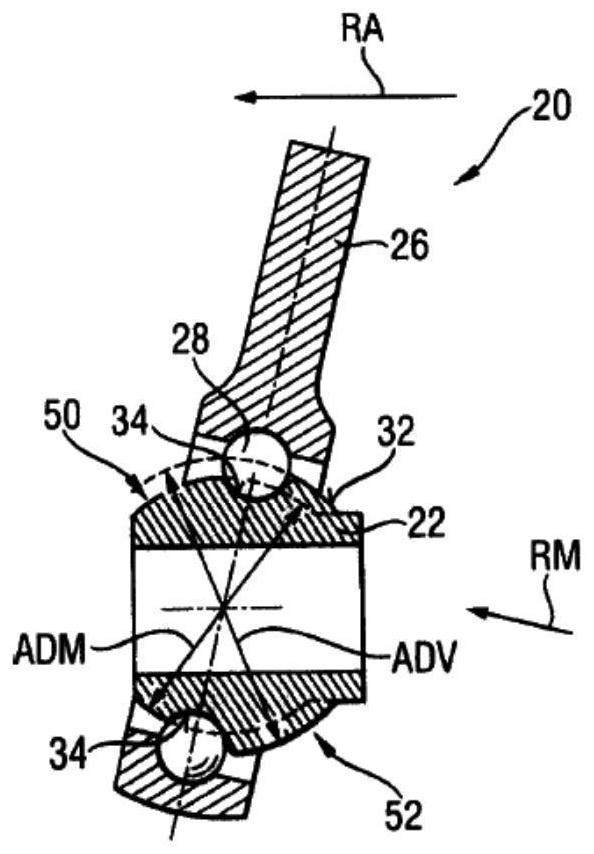

[0106] Such as Figure 7 to Figure 12 As shown, a composite bearing designed by the present invention.

[0107] Combined bearings are used in general machinery, such as rolling mills, underground drilling, crushing and grinding equipment, plunger pumps, internal combustion engines, electric tools, wind power equipment, helicopter rotor mechanisms and other fields.

[0108] in accordance with Figure 7 to Figure 12 As the first embodiment of the bearing, the combined bearing has an outer bearing ring 1 and an inner bearing ring 2 coaxial with the outer bearing ring 1, and as a multi-row rolling body 3, 123, 124 can be used in the raceway surface of the inner cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com