Lightweight lifting device suitable for linear walking

A lifting device and straight-line walking technology, which is applied in the direction of walking mechanism, transportation and packaging, and load hanging components, etc., can solve the problems of high labor intensity, small space in the assembly area, and unreliable fixing methods, so as to reduce labor intensity and avoid winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

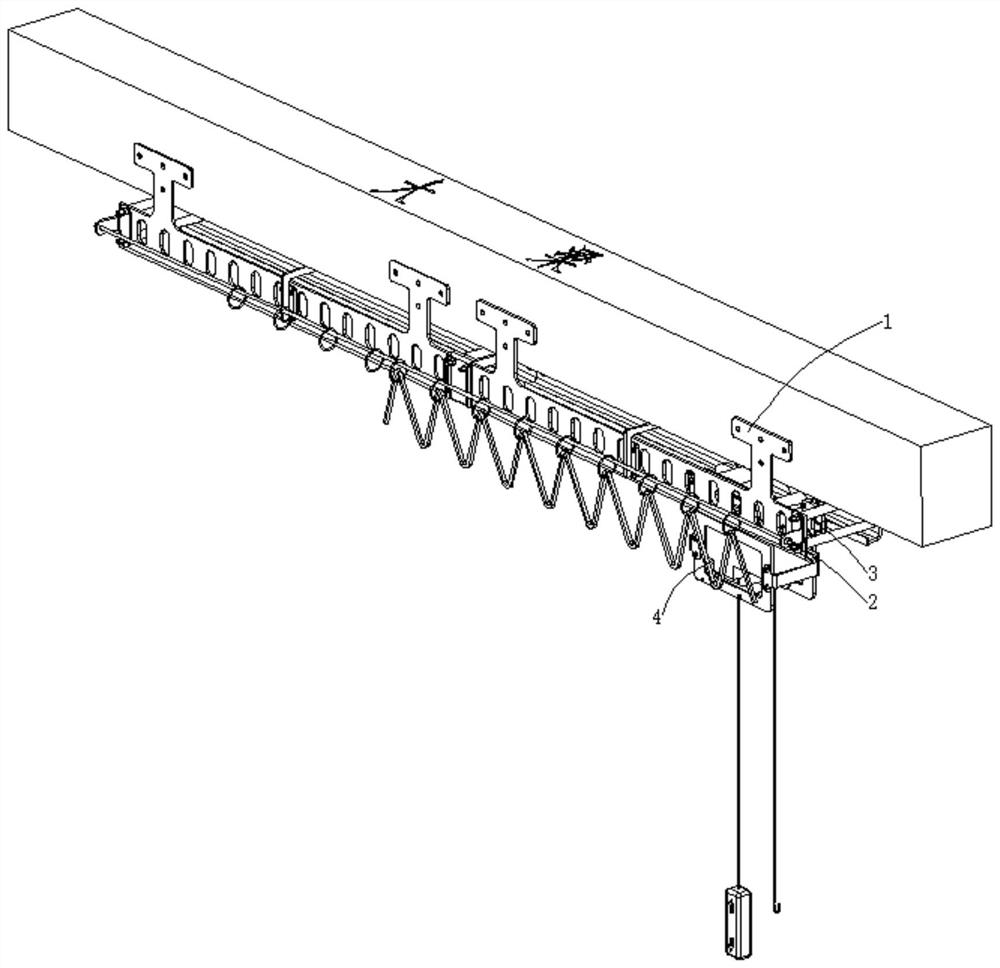

[0038] The light-weight lifting device suitable for straight-line walking of the present invention uses the electric hoist 4 to hoist the driving wheel assembly, and the worker pulls the walking trolley 3 loaded with the electric hoist 4 to move along the guide rail assembly 1, greatly reducing labor intensity.

Embodiment 2

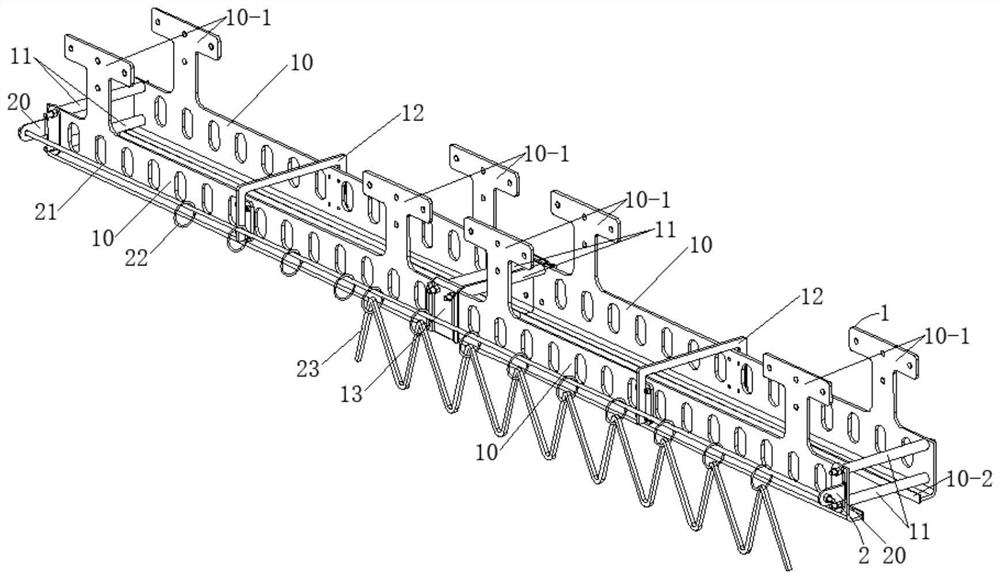

[0040] On the basis of Embodiment 1, the guide rail assembly 1 includes a bending guide plate 10, an inner limiting spacer 11, an outer limiting member 12 and a connecting piece 13, the bending guide plate 10 is arranged symmetrically, and the bending guide plate The upper end of 10 is provided with a fixed connecting plate 10-1, and the two ends of the inner limit spacer 11 are respectively fastened to the bending guide plate 10, and the symmetrically arranged bending guide plate 10 is stretched, and the outer limiter 12 The two ends are respectively fastened to the outer wall of the bending guide plate 10, and the positions of the adjacent bending guide plates 10 on the same side are connected through the connecting piece 13. The bending guide plate 10 is an assembled and spliced guide rail. Part 13 can be freely matched, the spliced guide rail is more flexible, and the installation method saves space.

[0041] The lower end of the bending guide plate 10 is bent 90° to t...

Embodiment 3

[0043]On the basis of Embodiment 1, the towing wire assembly 2 includes an outrigger 20, a guide rod 21, a hanging ring 22 and a cable 23, and the outrigger 20 is fastened to the end of the outer wall of the bending guide plate 10, The two ends of the guide rod 21 are fastened to the outrigger 20 respectively, and the hanging rings 22 are provided with a plurality of sleeves on the guide rod 21, and the cables 23 are hung by the hanging rings 22, so that the cables 23 can be accommodated and unfolded along with the movement of the walking trolley 3, so as to avoid the entanglement of the cable 23.

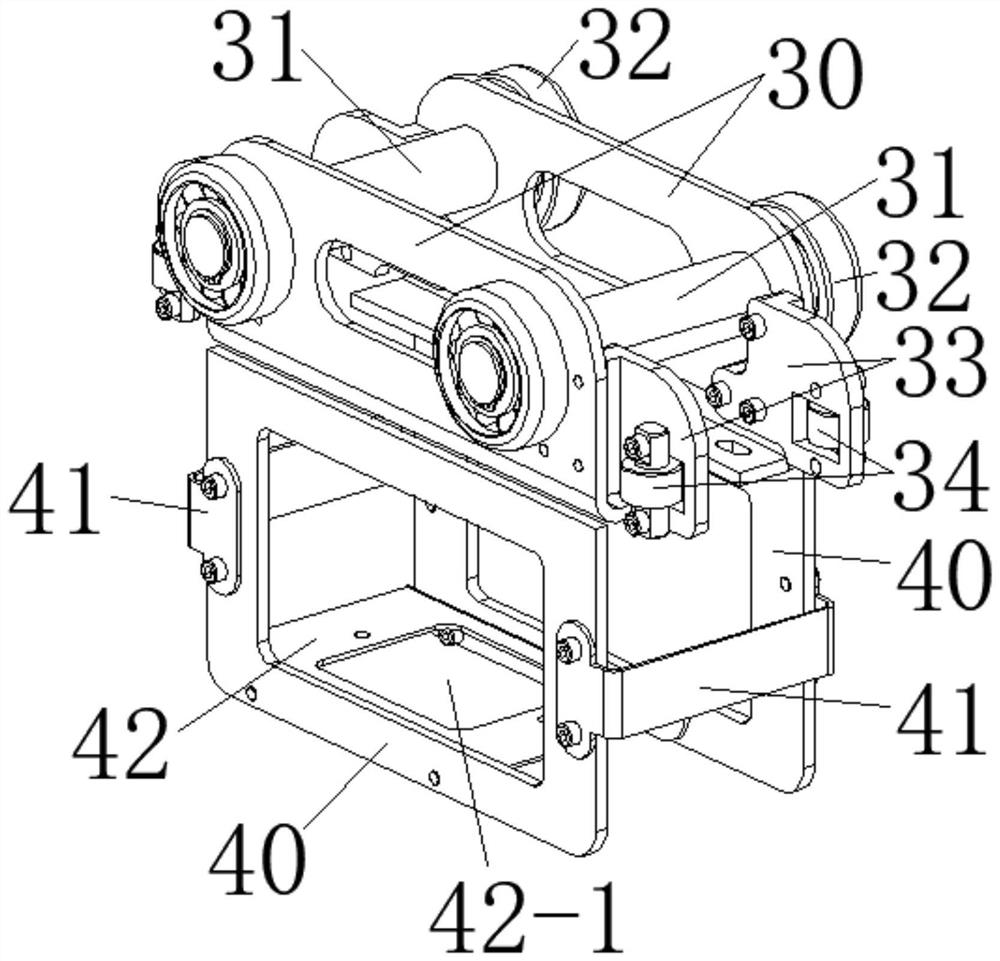

[0044] The walking trolley 3 includes a bending wheel frame 30, a wheel shaft 31, a load-bearing roller 32, a side wheel frame 33 and a limit roller 34. The bending wheel frame 30 is provided with two, and symmetrically arranged, and the two folding wheels Wheel shafts 31 are arranged between the bending wheel frames 30, and the two ends of the wheel shafts 31 are respectively rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com