Cartridge stern and assembling method of cartridge stern

An assembly method and stern technology, which is applied to ammunition, offensive equipment, projectiles, etc., can solve the problems of reducing the assembly efficiency of artillery shells and inconvenient assembly of guided artillery shells, and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0037] It should be noted that the shell stern of the embodiment of the present invention can effectively reduce the rotational speed of the shell, improve the measurement accuracy of motion parameters, and further enhance the control effect.

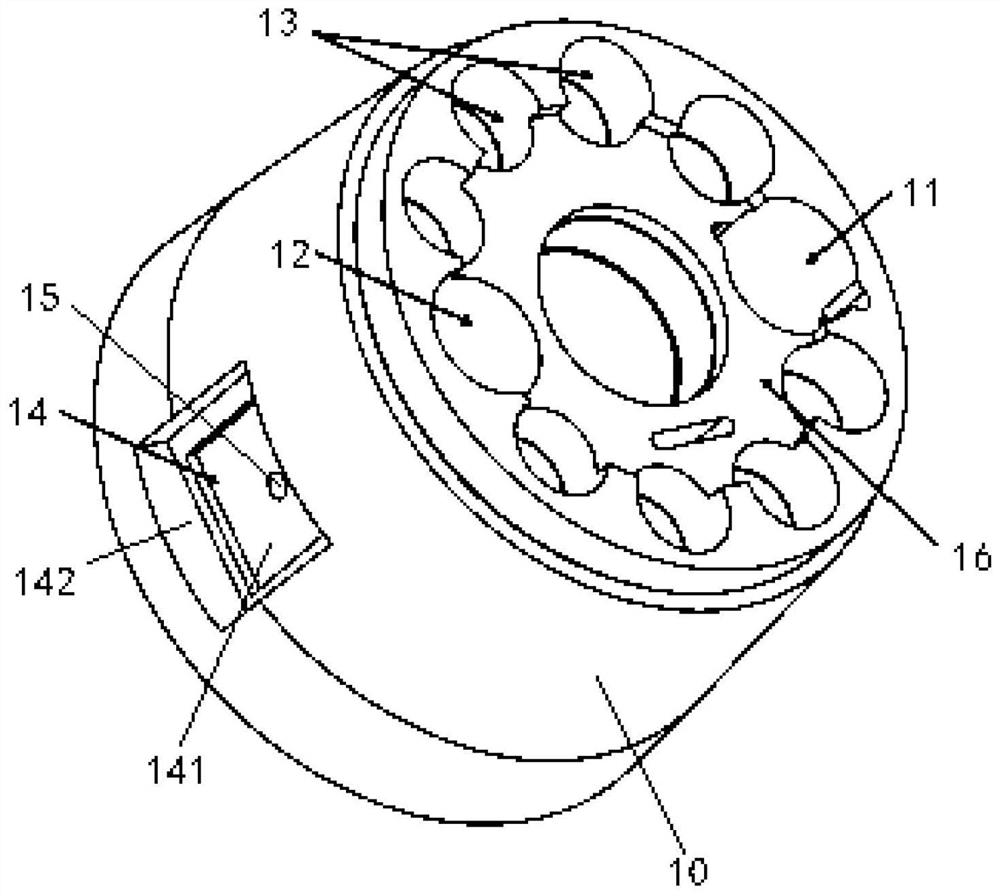

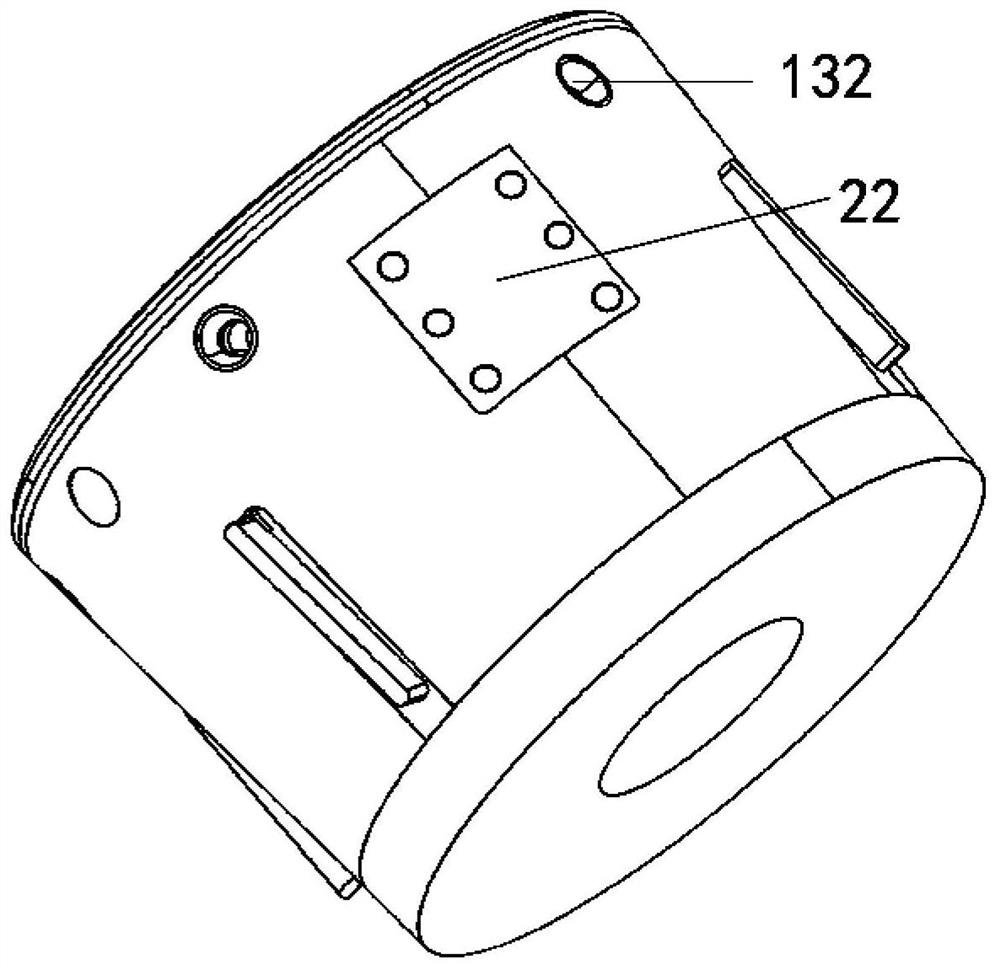

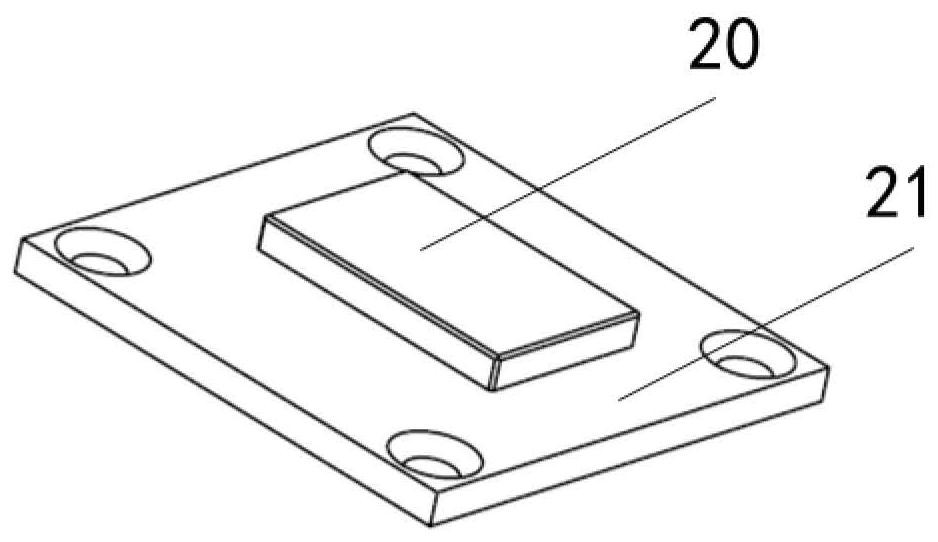

[0038] like Figure 1 to Figure 5As shown, an embodiment of the present invention provides a shell stern. The shell stern includes a casing 10 , a satellite measurement module, an electronic cabin module 30 , a plurality of pulse motors 40 and an energy cabin module 50 . Wherein, the housing 10 includes a body, an electronic cabin cavity 11, an energy cabin cavity 12, a plurality of installation cavities 13 and an antenna installation slot 14 positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com