Gear convenient to disassemble and assemble and used for mechanical equipment

A technology of mechanical equipment and gears, applied in mechanical equipment, portable lifting devices, belts/chains/gears, etc., can solve the problems of inconvenient disassembly and assembly, dust entering the joint, pollution or erosion of the joint, etc. Easy to install and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

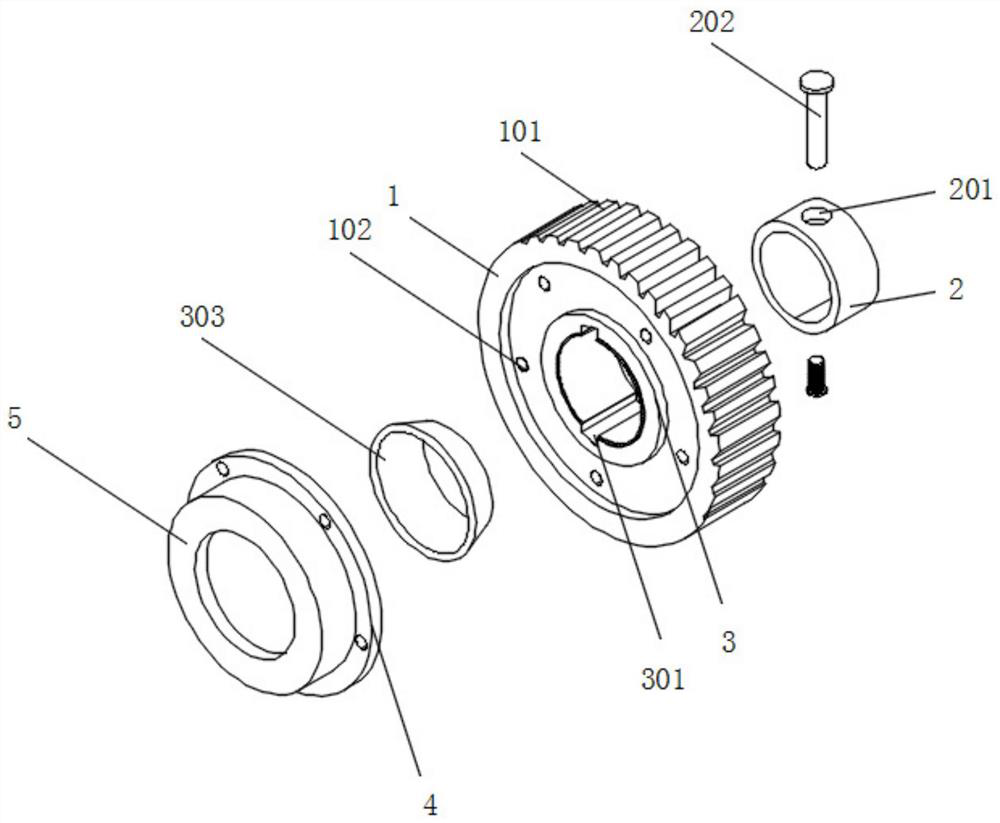

[0027] Embodiment 1 includes a gear body 1 and a fixed shaft 2. The fixed shaft 2 is installed on the back of the gear body 1. Several teeth 101 are installed on the outside of the gear body 1. The front of the gear body 1 is symmetrically provided with a first installation hole. 102. The gear body 1 is a part used for transmission. The teeth 101 provided on the outside of the gear mesh with each other to play the role of transmission. There are many types of gears, and the shapes of the gears are different. The resulting use effect It is also different, the teeth 101 play the role of connection, the top and bottom of the fixed shaft 2 are symmetrically provided with a fixed hole 201, and the inner side of the fixed hole 201 is installed with a fixed pin 202, and the fixed shaft 2 provides space for the opening of the fixed hole 201 , to provide tail vertebrae for the fixing of the gear during installation, the fixing hole 201 provides space for the fixing of the gear, and the ...

Embodiment 2

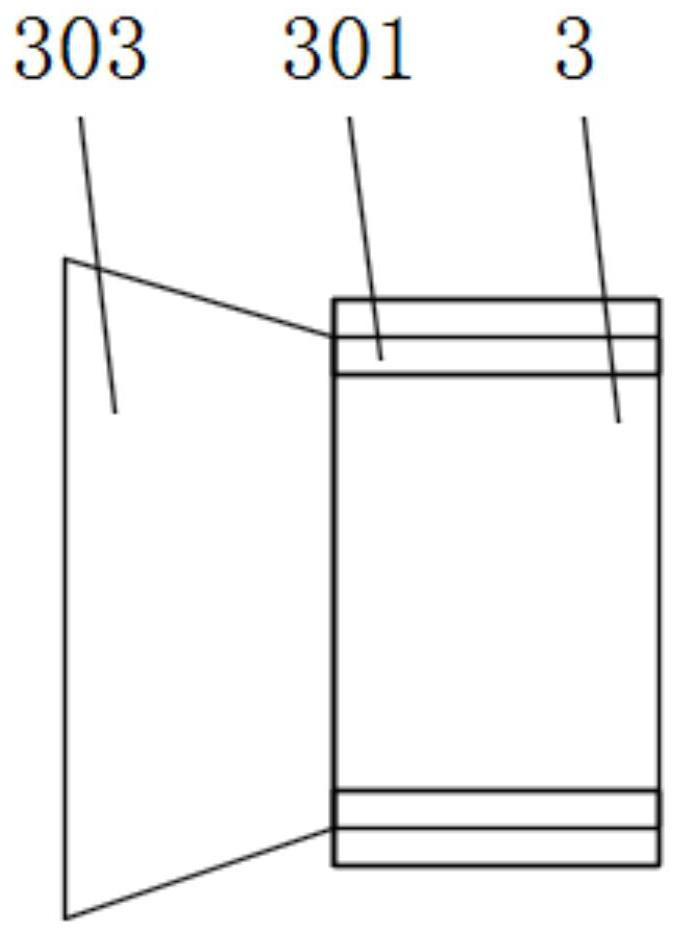

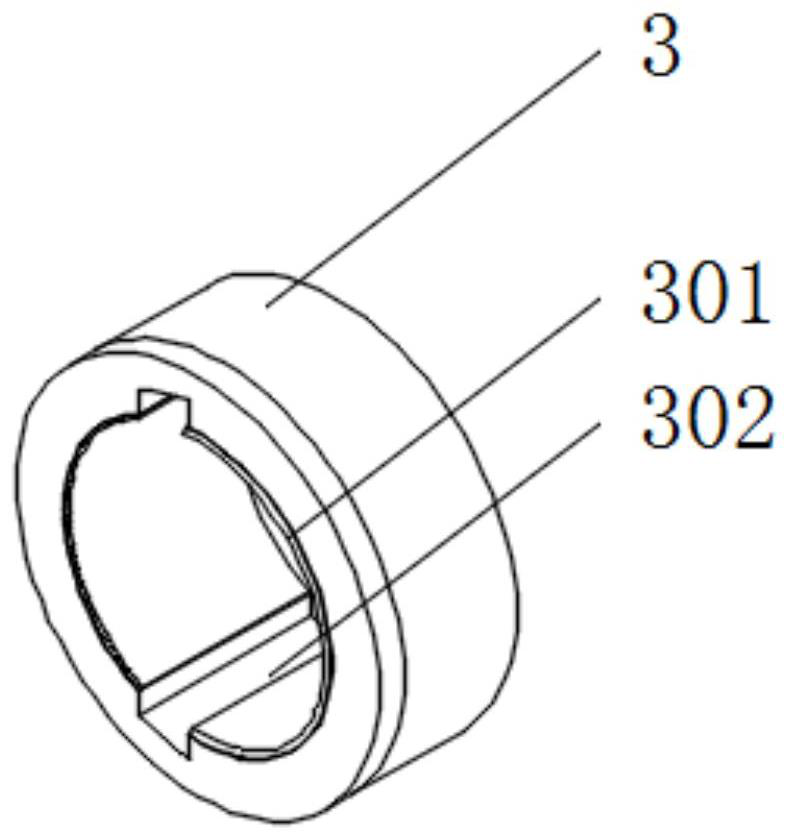

[0029] The second embodiment includes the installation shaft 3, the inside of the gear body 1 is installed with the installation shaft 3, the inner side of the installation shaft 3 is installed with a dismounting pad 302, and the top and bottom insides of the installation shaft 3 are individually and symmetrically provided with fixing grooves 301, and fixed The groove 301 is located on one side of the removal pad 302, and the front of the installation shaft 3 is installed with an installation sleeve 303. The installation shaft 3 plays a role of connection, so that the gear body 1 can be installed, and provides a function for the installation of the gear body 1, passing through the removal pad 302 to make the gear body 1 more convenient for disassembly and assembly. The inside of the installed rod and the installation shaft 3 can be prevented from rusting through the dismounting pad 302, making it difficult for the gear to be disassembled. The gear body 1 can be made It is conve...

Embodiment 3

[0031] Embodiment 3, including installation, 4 and sealing cover 5, the front of the gear body 1 is installed with a mounting part 4, and the front of the mounting part 4 is symmetrically provided with a plurality of second mounting holes 401, and the second mounting holes 401 are connected with the first mounting The holes 102 correspond to each other, and the mounting part 4 plays the role of installation, which is the installation passage position of the sealing cover 5, and enables the second mounting hole 401 to be opened at the same time, and the second mounting hole 401 provides space for the fixing of the mounting part 4, and the mounting part 4 is equipped with a sealing cover 5 on the front of the sealing cover 5, and a through hole 501 is provided on the front of the sealing cover 5. The sealing cover 5 plays a role of sealing and can prevent dust from entering the inner connection of the installation shaft 3. There are through holes 501, and the through holes 501 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com