Method for loading metal clusters on photocatalyst

A photocatalyst and metal-loading technology, applied in the field of photocatalysis, can solve the problems of large particle size, poor uniformity, and easy agglomeration of crystal grains, and achieve the effects of simple loading process, improved utilization rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 200mg TiO 2 , 10mg nano-Ag particle dispersion, add water to 30ml, stir and disperse, put it in a 50ml hydrothermal kettle. Set the hydrothermal temperature to 100°C, the stirring speed to 100rpm, and the reaction time to 14h. After cooling, wash with deionized water for 3 times to prepare TiO loaded with Ag clusters. 2 Composite photocatalytic materials.

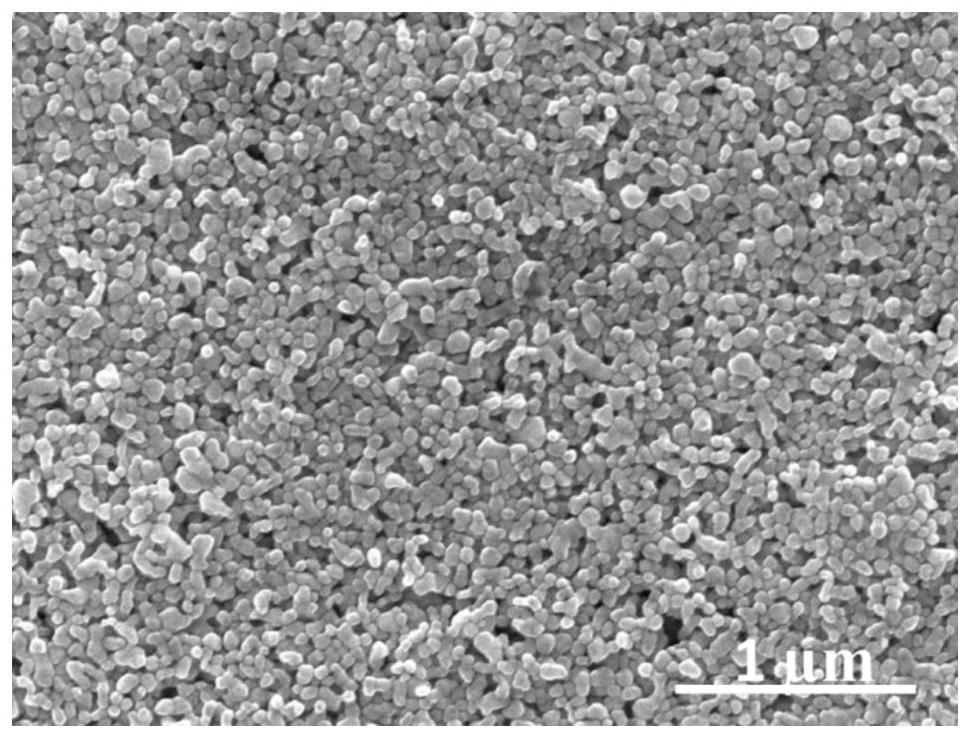

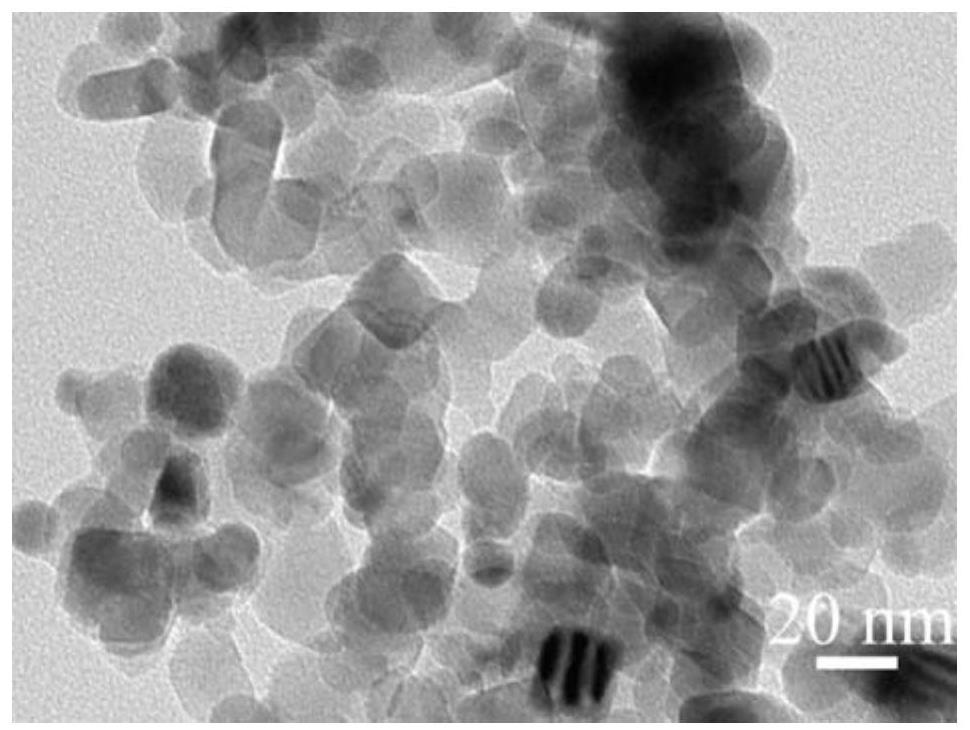

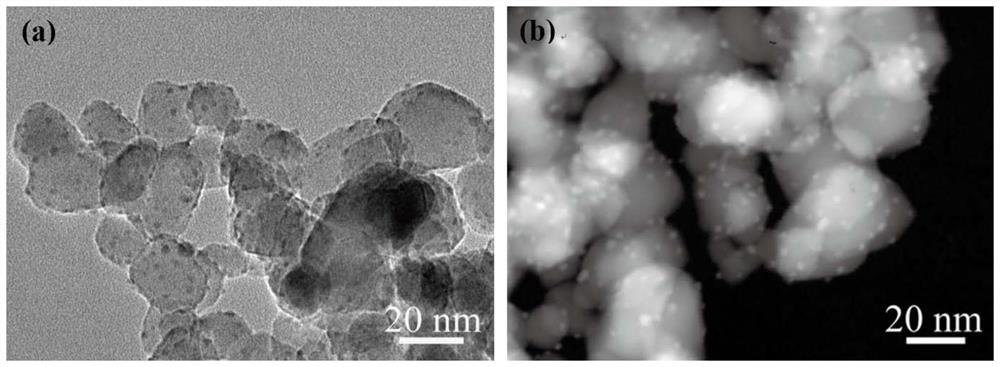

[0035] figure 1 is the SEM image of the Ag nanoparticles of the precursor, figure 2 TiO before loading Ag 2 TEM image of the photocatalyst. image 3 TiO after loading Ag 2 TEM and STEM images of the photocatalyst. From figure 1 It can be seen that the average size of Ag nanoparticles as a precursor is about 17nm. Depend on image 3 It can be seen that after the hydrothermal reaction, the larger Ag nanoparticles have disappeared, and only TiO 2 The particles are loaded with smaller Ag clusters with an average particle size of about 2 nm, which are uniformly distributed on the TiO 2 particle surface. ...

Embodiment 2

[0037] Weigh 12gNaOH, 200mg TiO 210mg of nano Ag particle dispersion liquid, add water to make up to 30ml, stir and disperse, put it into a 50ml hydrothermal kettle. Set the hydrothermal temperature to 130°C, the stirring speed to 300rpm, and the reaction time to 24h. After cooling, wash with deionized water until neutral to obtain Na 2 Ti 3 o 7 / Ag cluster composites, where Na 2 Ti 3 o 7 The nano-Ag clusters loaded on the surface of the nanotubes are evenly distributed, and the size is about 2nm ( Figure 4 ).

Embodiment 3

[0039] Weigh 200mg g-C 3 N 4 , 10mg nano-Ag particle dispersion, add water to 30ml, stir and disperse, put it in a 50ml hydrothermal kettle. Set the hydrothermal temperature to 150°C, the stirring speed to 300rpm, and the reaction time to 16h. After cooling, wash with deionized water for 3 times to prepare g-C loaded with Ag clusters. 3 N 4 Composite photocatalytic material ( Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com