Bolt screwing monitoring method and system based on BIM

A bolt and position technology, applied in the field of bolt tightening monitoring based on BIM, can solve problems such as bolt torque inspection, bolt prestress and design value gap, bridge structure safety hazards, etc., to avoid missing screw, avoid torque shortage or torque The effect of exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described embodiments It is a part of the embodiments of this application, but not all of them. Based on the embodiments in the present application, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present application.

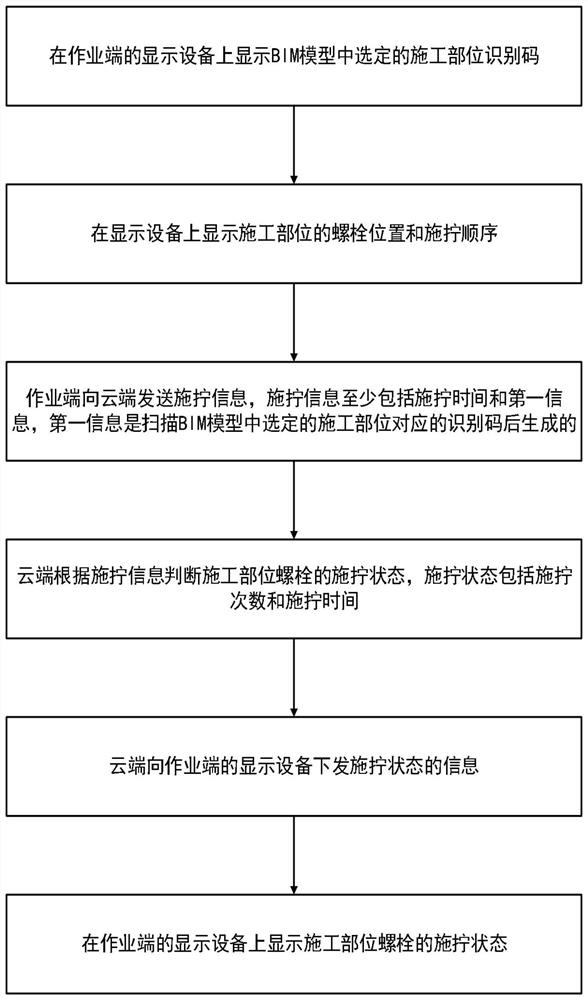

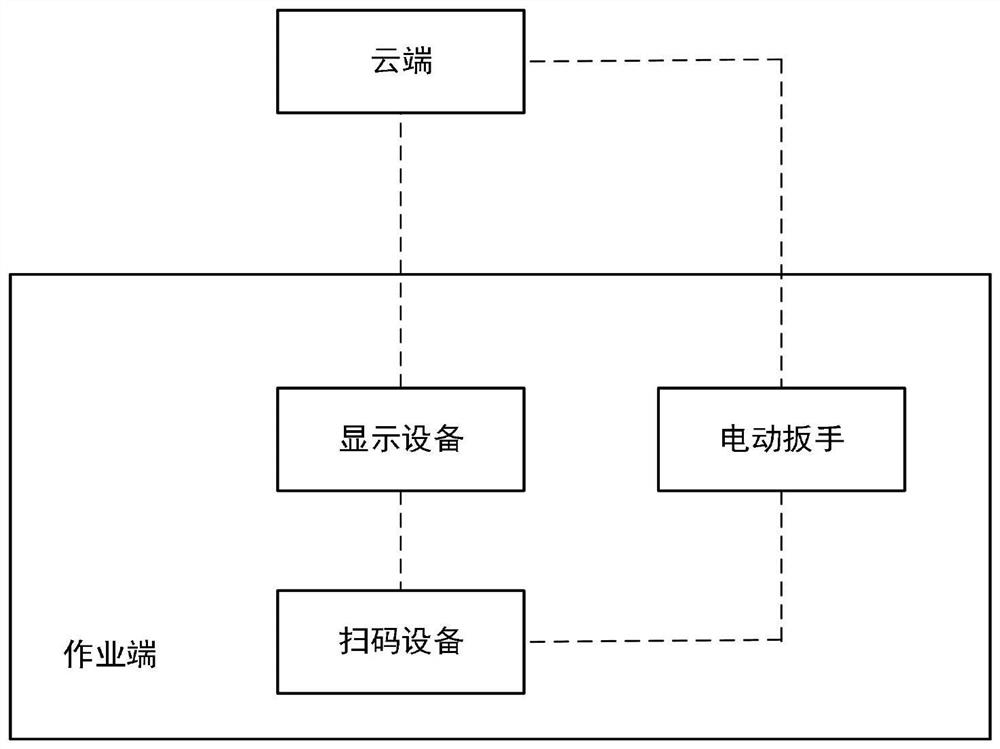

[0059] see figure 1 As shown, the embodiment of the present application provides a BIM-based bolt tightening monitoring method, which includes the following steps:

[0060]Display the identification code of the construction site selected in the BIM model on the display device at the operation end. Among them, the building information m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com